Landfill

Landfill Definition

A landfill is an engineered waste containment system designed to isolate municipal, industrial, or hazardous waste from surrounding soil, groundwater, and atmosphere through controlled structural layers, impermeable barriers, and long-term environmental protection measures.

Technical Parameters and Engineering Specifications

Modern landfill systems are governed by strict technical parameters to ensure environmental compliance and long service life.

| System Component | Typical Specification | Reference Standard |

|---|---|---|

| Primary Liner Thickness | 1.5–2.5 mm HDPE | GRI-GM13 / ASTM |

| Hydraulic Conductivity | ≤ 1×10⁻¹³ m/s | ASTM D5887 |

| Leachate Collection Layer | 300–500 mm gravel or geonet | EN / ASTM |

| Geotextile Protection | 300–800 g/m² nonwoven | ASTM D5261 |

| Slope Stability Factor | ≥ 1.3 (static) | Geotechnical Design |

Structural Layers and Material Composition

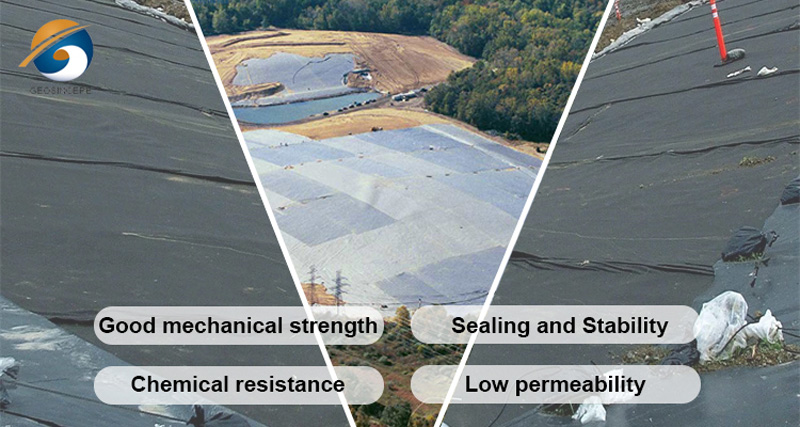

A landfill system functions as a composite structure composed of multiple engineered layers.

Waste Mass: Compacted municipal or industrial waste

Daily / Intermediate Cover: Soil or alternative cover materials

Leachate Collection System: Drainage gravel, pipes, or geonets

Geomembrane Liner: HDPE or LLDPE impermeable barrier

Geosynthetic Clay Liner (Optional): Secondary containment

Compacted Subgrade: Prepared foundation layer

Manufacturing and System Preparation Process

Geomembrane Manufacturing

Polymer resin formulation with stabilizers

High-temperature extrusion and calendering

Thickness calibration and surface texturing

Online inspection and quality control testing

Landfill System Installation Process

Subgrade compaction and grading

Deployment of geotextile protection layers

Geomembrane liner placement and welding

Non-destructive and destructive seam testing

Leachate drainage layer installation

Industry Comparison: Landfill vs Other Waste Disposal Systems

| System Type | Environmental Control | Capital Cost | Typical Use |

|---|---|---|---|

| Engineered Landfill | High | Medium | Municipal & industrial waste |

| Open Dumping | Low | Low | Unregulated disposal |

| Incineration | Medium | High | Hazardous waste reduction |

| Recycling Facility | High | High | Material recovery |

Application Scenarios and Stakeholders

Landfill systems are specified and executed by multiple professional roles.

EPC Contractors: Turnkey landfill construction projects

Municipal Authorities: Urban solid waste management

Industrial Operators: Hazardous and by-product disposal

Distributors & Importers: Supply of geomaterials and liners

Core Engineering Pain Points and Solutions

Leachate Leakage: Mitigated through composite liner systems

Groundwater Contamination: Controlled by ultra-low permeability barriers

Slope Instability: Addressed using textured geomembranes and analysis

Long-Term Degradation: Managed via UV- and chemical-resistant materials

Risk Warnings and Mitigation Strategies

Improper welding can compromise liner integrity

Inadequate drainage increases hydraulic head pressure

Unprotected liners risk puncture during waste placement

Insufficient monitoring may delay leak detection

Procurement and Selection Guide

Identify waste classification and regulatory requirements

Define liner thickness and material type

Select compatible geotextiles and drainage layers

Verify manufacturer certifications and test reports

Evaluate installation support and QA/QC procedures

Plan long-term monitoring and maintenance strategy

Engineering Case Example

A municipal landfill expansion project utilized a double-liner system consisting of 2.0 mm HDPE geomembrane, geosynthetic clay liner, and leachate collection geonets. The system achieved regulatory approval and ensured groundwater protection over a projected 40-year operational period.

Frequently Asked Questions (FAQ)

Q1: What is the main purpose of a landfill liner?

To prevent leachate migration.Q2: Which liner material is most common?

HDPE geomembrane.Q3: How long does a landfill last?

Typically 30–50 years or more.Q4: Is a single liner sufficient?

Depends on waste classification.Q5: What causes liner failure?

Poor installation or mechanical damage.Q6: Are geotextiles mandatory?

Yes, for protection and filtration.Q7: Can landfills handle hazardous waste?

With enhanced containment systems.Q8: How is leachate managed?

Through drainage and collection pipes.Q9: Is gas management required?

Yes, for methane control.Q10: Can materials be tested before procurement?

Yes, samples and reports are standard.

Call to Action

For landfill system design support, material specifications, or procurement quotations, request technical documentation, engineering consultation, or material samples from qualified suppliers.

E-E-A-T Author Credentials

This content is developed by professionals with extensive experience in landfill engineering, geosynthetic materials, and environmental infrastructure projects, referencing international standards and real-world EPC applications.