The Enduring Shield: HDPE Geomembranes in Modern Geosynthetic Engineering

HDPE Geomembranes stand as a cornerstone technological know-how inside the geosynthetics industry. Representing a state-of-the-art fusion of polymer science and large-scale engineering, these impermeable liners grant vital containment options throughout diverse, traumatic environments. Their ascendancy is no longer unintended however rooted in a special mixture of bodily robustness, chemical resilience, and long-term performance, making them the material of preference for tasks the place failure is now not an option.

1. HDPE Geomembranes: The Molecular Foundation of Performance

The splendid residences of HDPE geomembranes originate at the molecular level. HDPE is a semi-crystalline thermoplastic polymer characterised with the aid of its excessive diploma of polymerization and minimal chain branching. This linear shape lets in polymer chains to pack tightly together, ensuing in:

1.1 HDPE Geomembranes - High Density (0.940–0.965 g/cm³)

Directly contributing to choicest tensile strength, puncture resistance, and dimensional balance in contrast to lower-density polyethylenes (LDPE, LLDPE).

1.2 HDPE Geomembranes - Elevated Crystallinity (Typically 60-80%)

The ordered crystalline areas impart stiffness, hardness, and superior barrier properties, whilst the amorphous areas grant some flexibility.

1.3 HDPE Geomembranes - Outstanding Chemical Resistance

HDPE reveals incredible inertness. It is exceptionally resistant to a widespread array of aggressive chemicals, which includes sturdy acids, robust alkalis, salts, and many natural solvents. This makes it best for containing leachate, industrial manner liquids, brine solutions, and acid mine drainage.

1.4 HDPE Geomembranes - Low Permeability

The tight molecular packing creates an awesome barrier to beverages and gases. Measured by means of water vapor transmission charges (ASTM E96) or precise chemical permeation coefficients (ASTM F739), HDPE persistently demonstrates extraordinarily low values, making sure dependable containment.

1.5 HDPE Geomembranes - Excellent Environmental Stress Crack Resistance (ESCR)

A essential overall performance indicator, ESCR (ASTM D5397, ASTM D1603) measures the material's capacity to face up to cracking below sustained tensile stress in the presence of surfactants or different crack-promoting agents. Premium HDPE geomembrane liner is formulated with strong resin structures to obtain very excessive ESCR ratings, quintessential for long-term integrity beneath load.

2. HDPE Geomembranes Manufacturing Precision: From Resin to Roll

Producing HDPE geomembrane sheet includes state-of-the-art extrusion processes, primarily:

2.1 Blown Film Extrusion: Molten HDPE resin is extruded vertically via an annular die, forming a non-stop tube inflated with the aid of inner air pressure. This creates a bubble which is cooled, collapsed, and wound onto rolls. This approach inherently creates a bi-axially oriented sheet, frequently yielding greater tear strengths and higher thickness uniformity throughout the width in contrast to flat die.

2.2 Flat Die (Cast) Extrusion: Resin is extruded horizontally thru a straight, wide-slot die without delay onto a large-diameter casting roll or via a water bathtub for cooling. This method lets in for very excessive line speeds and specific thickness manipulate however may also show off barely much less transverse orientation than blown film.

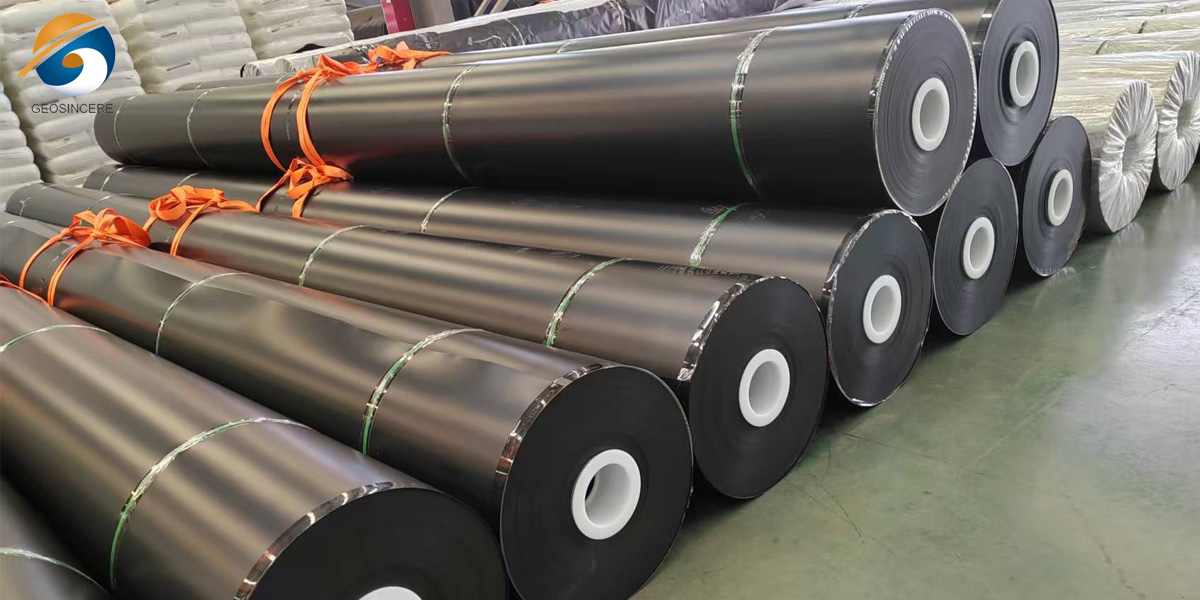

Critical manufacturing parameters consist of particular temperature manage during extrusion, meticulous cooling regimes to optimize crystallinity and reduce residual stresses, and rigorous on-line thickness monitoring (typically the use of beta-gauge systems). The ensuing rolls, frequently 1.5mm to 3.0mm thick and 5m to 9m wide, need to show off steady thickness, clean or textured surfaces as specified, and be free from gels, pinholes, and inclusions.

3. The Imperative of HDPE Geomembranes Quality Assurance and Standards

Given their fundamental function, HDPE geomembranes are ruled by way of stringent worldwide requirements and high-quality manage protocols. Key requirements include:

3.1 GRI-GM13: The Geosynthetic Research Institute's Standard Specification for Test Methods, Test Properties and Testing Frequency for High Density Polyethylene HDPE Smooth geomembrane and Textured Geomembrane. This is the most extensively referenced procurement specification globally, defining minimal values and take a look at frequencies for houses like thickness, density, soften index, tensile properties, tear resistance, puncture resistance, carbon black content material & dispersion, oxidative induction time (OIT - ASTM D3895/D5885), stress crack resistance (ASTM D5397), and seam peel & shear power (ASTM D6392, D4437).

3.2 ASTM Standards: Numerous ASTM International requirements cowl unique check techniques applicable to HDPE geomembranes (e.g., D5199 for thickness, D792 for density, D1505 for density gradient, D6693 for tensile properties, D4833 for puncture, D5884 for tear resistance).

3.3 Certification: Reputable producers bear third-party certification packages (e.g., GSI-GCL, CertiPUR, site-specific certifications) involving ordinary audits and unbiased checking out to confirm steady compliance with specifications.

Critical resin residences monitored encompass Melt Flow Index (MFI - ASTM D1238), indicating molecular weight and processability, and OIT, a key indicator of antioxidant content material and long-term oxidative stability. Carbon black (typically 2-3%) is vital for UV resistance, requiring incredible dispersion (ASTM D5596) to stop localized degradation points.

4. HDPE Geomembranes Installation: Where Engineering Meets Craftsmanship

The high-quality houses of HDPE geomembranes can solely be absolutely realized thru flawless installation, worrying specialised expertise:

4.1 Subgrade Preparation: The basis have to be meticulously graded, compacted, and smoothed to put off sharp protrusions, rocks, or voids that ought to motive localized stress factors or punctures. Proper drainage layers below the liner can also additionally be required.

4.2 Panel Deployment & Alignment: Rolls are cautiously deployed, aligned, and allowed to thermally acclimate and relax, minimizing wrinkles and stresses earlier than seaming. Minimizing discipline seams enhances integrity.

4.3 Seaming: The most integral operation. Primary strategies are:Dual Hot Wedge Fusion (ASTM D6392): Heated wedges soften the surfaces of two overlapped sheets; stress rollers fuse them together, developing two parallel fusion seams with an air channel for testing.

4.4 Extrusion Filament Welding (ASTM D6392): Molten HDPE liner is extruded alongside the overlap between two sheets, bonding them together. Used for complicated details, patches, and repairs.

4.5 Thermal Fusion (for Textured): Specialized tools the usage of heated factors or warm air to fuse textured surfaces.

4.6 Chemical Fusion: Solvent-based adhesives used for precise purposes or repairs (less frequent for foremost seams). Rigorous non-destructive checking out (NDT - e.g., air lance trying out of twin seams, vacuum field trying out ASTM D5641, spark checking out ASTM D6365) and damaging seam checking out (peel/shear - ASTM D6392) are mandatory.

4.7 Anchoring & Protection: Secured inside anchor trenches and included through cowl soils (e.g., in landfills) or ballast (e.g., floating covers) or concrete buildings as per design. Careful placement of protecting geotextiles or sand layers above and beneath is frequently crucial.

5. HDPE Geomembranes Diverse Applications: The Ubiquity of Containment

The special houses of HDPE geomembranes force their deployment in severa high-stakes applications:

5.1 HDPE Geomembranes for Environmental Protection:

Landfill Liners & Caps (Base & Final): Primary and secondary liners stopping leachate migration into groundwater; caps decrease infiltration and manipulate landfill gas.

Contaminated Land Remediation: Capping and separating polluted soil or groundwater plumes.

Wastewater & Treatment Lagoons: Containing influent, effluent, and sludge.

Potable Water Reservoirs: Preventing illness and evaporation.

5.2 HDPE Geomembranes for Mining & Energy:

Heap Leach Pads: Containing aggressive cyanide or acid options used in metallic extraction.

Tailings Impoundments: Securing mine waste slurries, frequently in seismically lively areas.

Pond Liners (Process Water, Sedimentation, Decant): Critical for water administration and air pollution control.

Secondary Containment: Bunding for gasoline tanks and chemical storage.

5.3 HDPE Geomembranes for Water Resources:

Irrigation Canals & Ponds: Reducing seepage losses.

Aquaculture Ponds: Maintaining water degrees and quality.

Reservoirs & Dams: Seepage control, rehabilitation, and new construction.

Salt Evaporation Ponds.

5.4 HDPE Geomembranes for Industrial & Agricultural:

Secondary Containment: Spill prevention for industrial facilities.

Decorative Water Features.

Manure Storage Lagoons.

Floating Covers (Gas Collection, Evaporation Control).

6. HDPE Geomembranes Advantages Over Alternatives and Considerations

While PVC, LLDPE, fPP, and EPDM are additionally used, HDPE affords wonderful advantages:

- Superior Chemical Resistance: Especially to hydrocarbons and sturdy oxidizers in contrast to LLDPE or fPP.

- Highest Rigidity & Puncture Resistance: Crucial for aiding heavy cowl soils or waste loads.

- Best Long-Term Durability & ESCR: Proven provider existence exceeding 50+ years below splendid conditions.

- Wider Temperature Range: Performs properly in each excessive and low ambient temperatures.

- Cost-Effectiveness for Large Areas: Lower fabric fee per unit vicinity in contrast to many alternatives.

However, issues include:

- Lower Flexibility: Requires cautious subgrade prep and coping with to keep away from stress cracking at some stage in set up over uneven surfaces.

- Thermal Expansion/Contraction: Requires plan lodging (e.g., folds, wrinkles) and suitable anchoring.

- Seaming Complexity: Requires exceptionally knowledgeable welders and rigorous QA/QC.

7. HDPE Geomembranes Ensuring Longevity: The Role of Formulation and Protection

Long-term overall performance hinges on:

- Premium Resins: Utilizing excessive molecular weight, bimodal resins for optimum mechanical residences and ESCR.

- Advanced Stabilization Packages: Combinations of predominant (hindered phenolics) and secondary (phosphites, thioesters) antioxidants, alongside with UV stabilizers (HALS Hindered Amine - Light Stabilizers), grant protection towards thermal oxidation all through processing and long-term environmental degradation (UV, heat).

- Carbon Black: Essential UV protection; nice dispersion is paramount.

- Physical Protection: Proper cowl soil placement (avoiding giant angular rocks), use of shielding geotextiles, and minimizing publicity to direct daylight earlier than protecting notably prolong provider life.

8. The Future: HDPE Geomembranes Innovation and Refinement

HDPE geomembrane science continues to evolve:

- Enhanced Resins: Development of even higher-performance resins with accelerated low-temperature affect power or ESCR.

- Coextrusion: Layers with special residences (e.g., a conductive layer for leak vicinity surveys - ASTM D7007, or a shielding layer).

Advanced Texturing: Optimizing floor profiles for greater interface friction angles with soils and geosynthetics, integral for slope stability.

- Sustainability: Focus on resin sourcing, manufacturing efficiency, and end-of-life recyclability pathways.

9. Conclusion

GEOSINCERE Geosynthetics HDPE geomembranes are a ways greater than easy plastic sheets; they are engineered containment structures worrying a deep grasp of polymer science, manufacturing precision, rigorous best control, and meticulous installation. Their unparalleled aggregate of chemical resistance, mechanical strength, impermeability, and verified durability underpins their crucial function in safeguarding the environment, managing necessary resources, and assisting industrial approaches globally. From the depths of landfills to the vastness of mining operations and the imperative infrastructure of water management, HDPE geomembranes characteristic as the indispensable, enduring protect upon which modern-day containment engineering relies. As fabric science advances and software needs develop extra complex, HDPE geomembranes will absolutely proceed to adapt, reinforcing their role as a critical geosynthetic solution.