Geosynthetic Clay Liners Landfill Liner Material

Geosynthetic Clay Liners (GCLs) are indeed innovative and highly effective materials used as landfill liners. They are designed to provide superior containment and environmental protection in waste disposal sites. GCLs combine the geotechnical properties of natural clays with the enhanced performance of geosynthetics, resulting in a versatile and reliable barrier system.

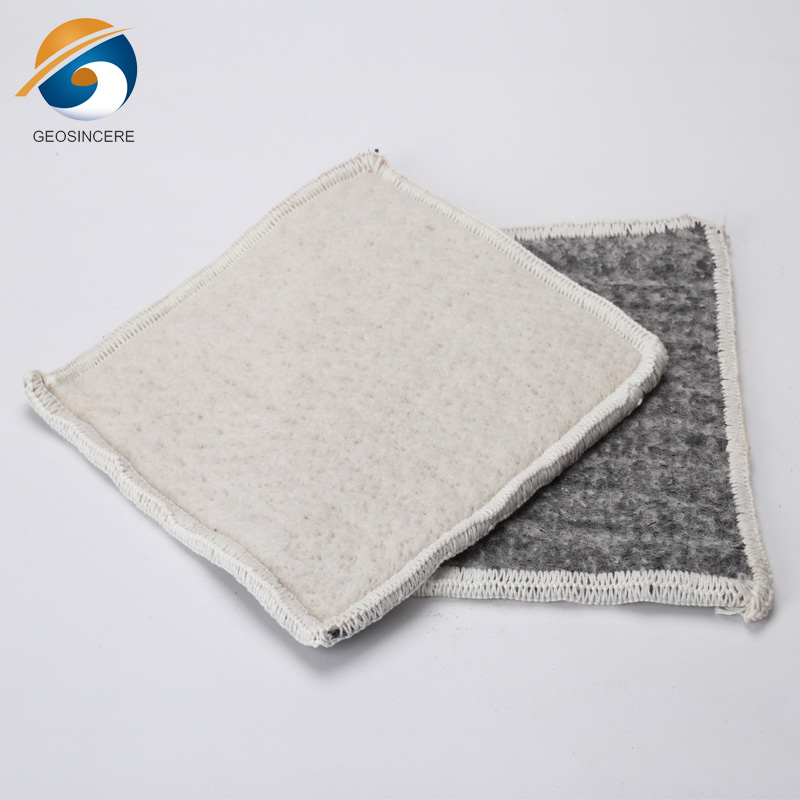

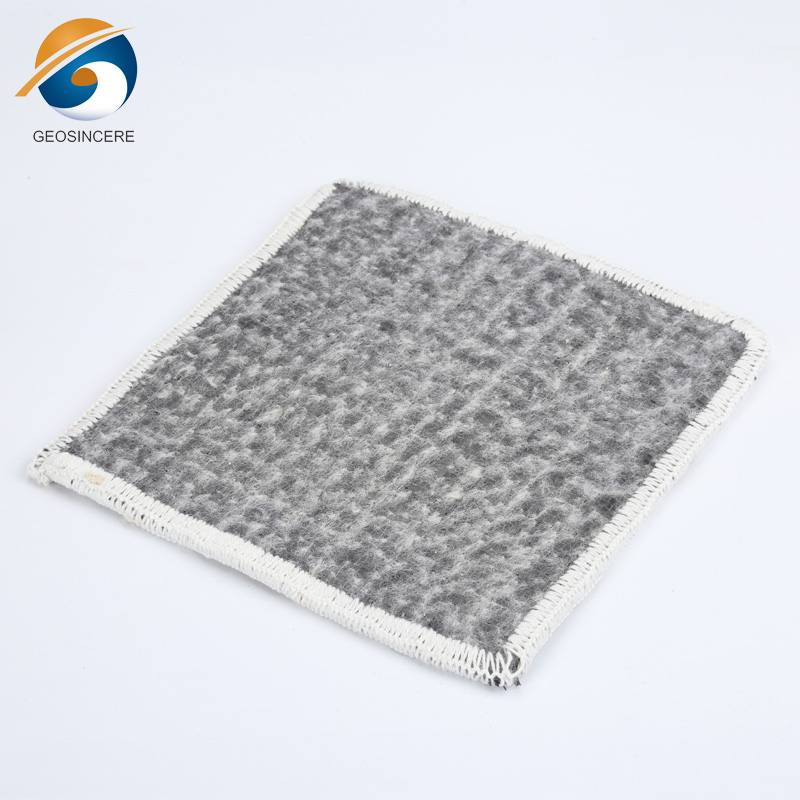

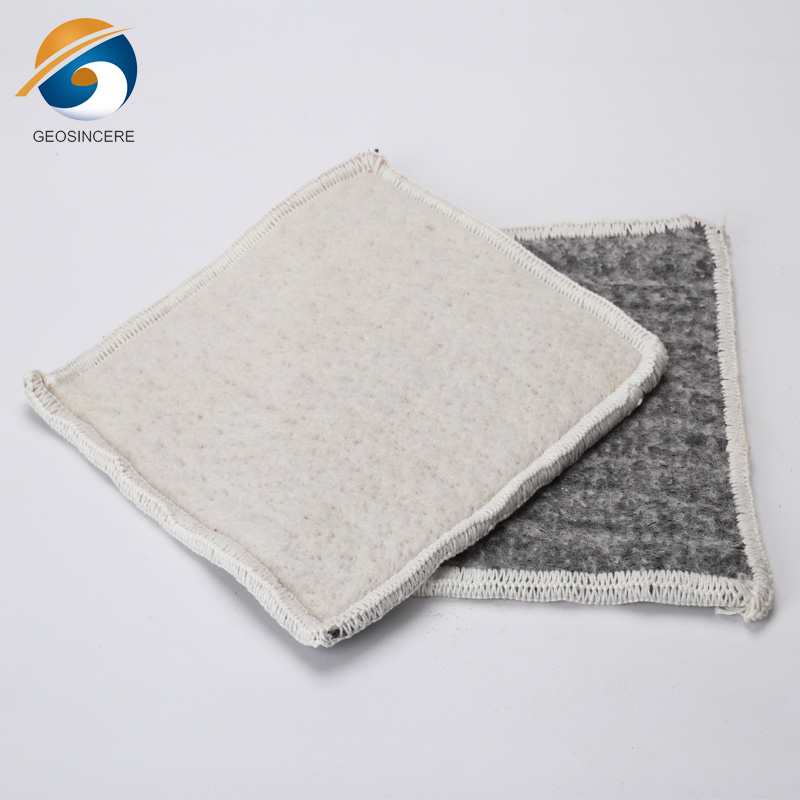

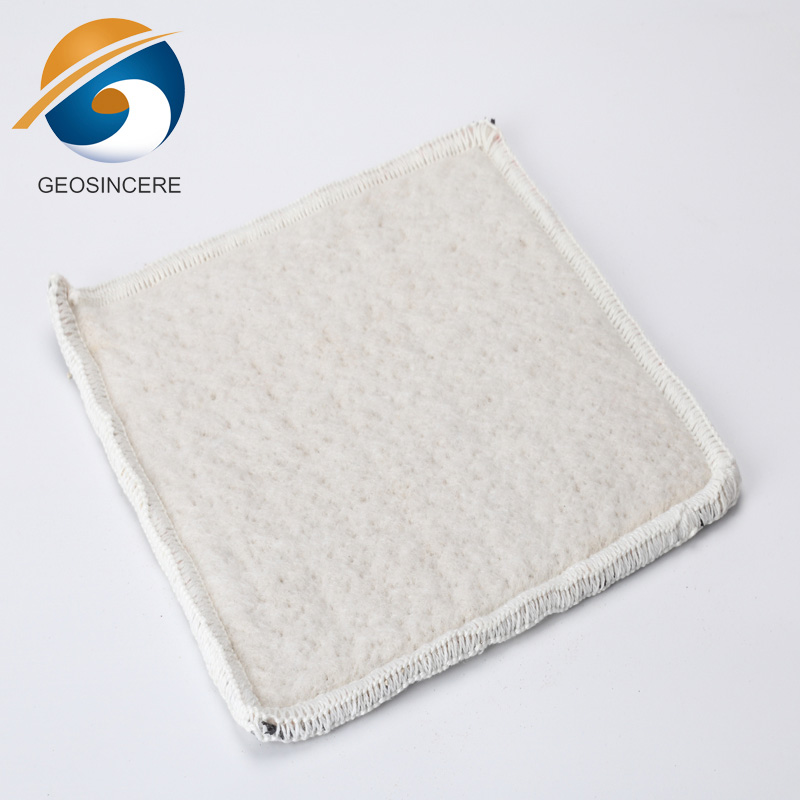

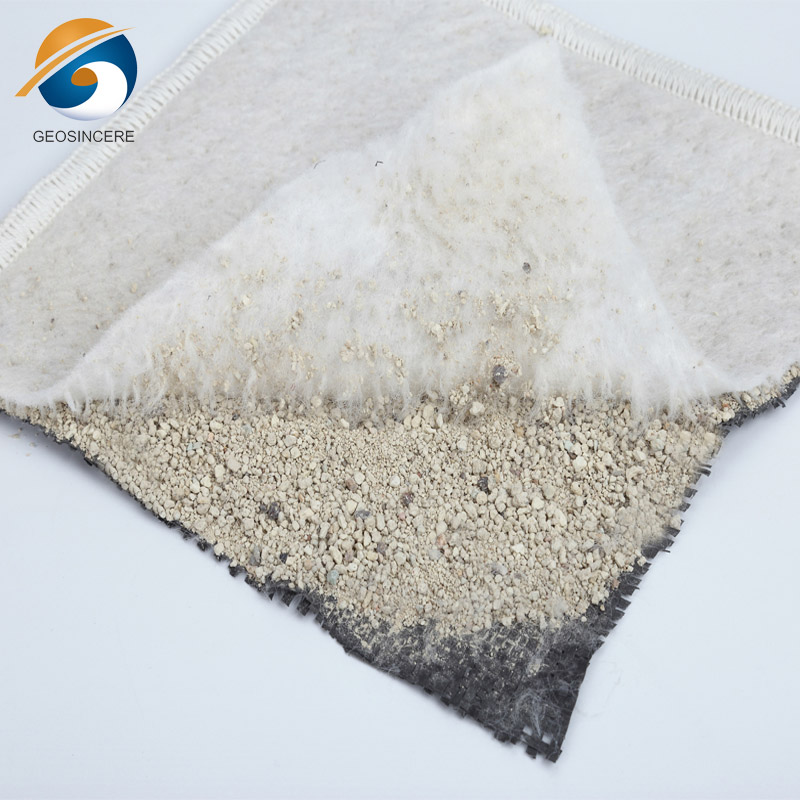

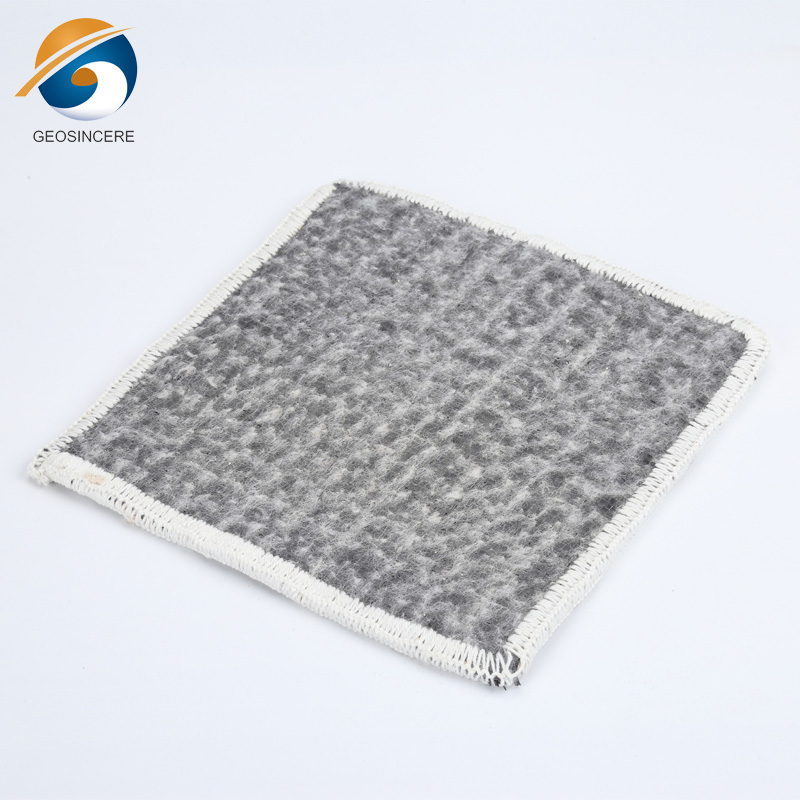

GCLs consist of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is a naturally occurring material known for its low permeability and swelling characteristics when hydrated. The geotextile layers, typically made of woven or non-woven synthetic materials, provide reinforcement and mechanical stability to the liner system.

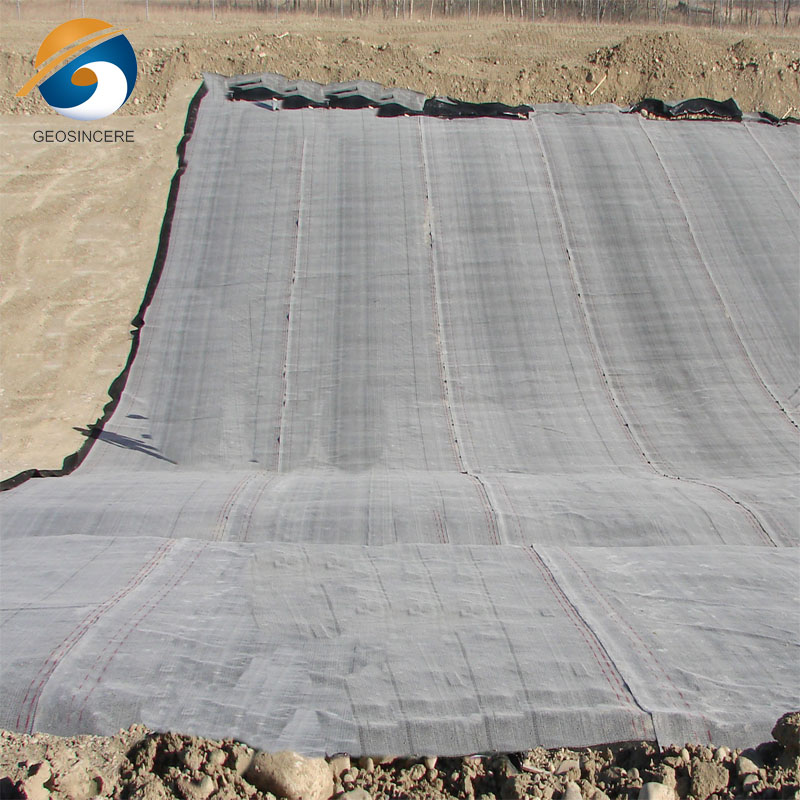

When it comes to reliable environmental protection in waste containment systems, Geosynthetic Clay Liners Landfill Liner Material is the industry gold standard. Known for its outstanding impermeability, ease of installation, and long-term durability, geosynthetic clay liners (GCLs) are essential in modern landfill construction, mining, and containment applications.

If you’re searching for an efficient, cost-effective, and environmentally sound liner system, Geosynthetic Clay Liners Landfill Liner Material is the solution you need.

What is Geosynthetic Clay Liners Landfill Liner Material?

Geosynthetic Clay Liners Landfill Liner Material consists of two layers of geotextiles (typically woven and non-woven fabrics) enclosing a layer of natural sodium bentonite clay. When hydrated, the bentonite swells to form a low-permeability barrier that rivals compacted clay liners at a fraction of the thickness and installation cost.

This advanced product provides exceptional sealing performance and resistance to chemical attack, making it ideal for municipal solid waste landfills, mining tailings, pond linings, and industrial containment systems.

Key Advantages of Geosynthetic Clay Liners Landfill Liner Material

| Feature | Benefit |

|---|---|

| Low Permeability | Effectively prevents leachate and fluid migration |

| Thin and Lightweight | Easier to transport and install than traditional clay liners |

| Self-Sealing Capability | Automatically seals minor punctures and overlaps |

| High Chemical Resistance | Protects against aggressive industrial waste and chemical exposure |

| Faster Installation | Reduces construction time and labor costs |

| Sustainable and Natural Bentonite | Eco-friendly and naturally occurring sealing material |

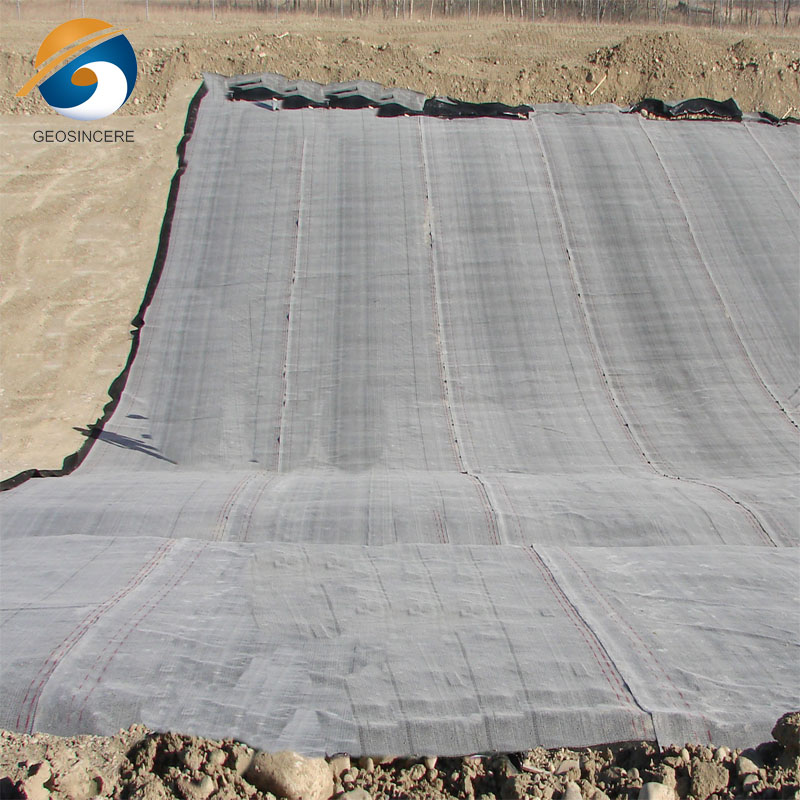

Applications of Geosynthetic Clay Liners Landfill Liner Material

✅ Municipal Solid Waste Landfills

✅ Hazardous Waste Landfills

✅ Mining and Tailings Ponds

✅ Industrial Waste Containment

✅ Water Reservoirs and Canals

✅ Secondary Containment Systems for Tanks and Pipelines

Why Choose Our Geosynthetic Clay Liners Landfill Liner Material?

As a trusted supplier in the geosynthetics industry, we offer high-performance Geosynthetic Clay Liners Landfill Liner Material engineered for maximum containment and compliance with global environmental standards. Here’s why industry professionals choose us:

🌍 Environmental Protection You Can Trust

Our liners prevent groundwater contamination and ensure long-term environmental safety.

💰 Cost-Effective Containment

Compared to compacted clay liners, GCLs reduce costs related to excavation, haulage, and installation time.

🛠 Easy Handling & Installation

Flexible rolls simplify deployment on steep slopes, irregular terrain, and narrow trenches.

🏗 Proven Performance

Backed by decades of successful landfill and containment projects worldwide.

Client Testimonial

“We’ve used Geosynthetic Clay Liners Landfill Liner Material on over 12 major landfill sites. Not only do they deliver excellent sealing performance, but installation was faster and significantly cheaper than traditional methods.”

— Robert H., Civil Engineer, Environmental Solutions Group

Technical Specifications (Example Product)

Bentonite Type: Natural sodium bentonite

Permeability: ≤1.0 × 10⁻⁹ cm/s

Weight: 5000 g/m²

Peel Strength: ≥600 N/m

Roll Size: Customizable widths and lengths available

Compliance: ASTM D5887 / GRI-GCL3 / ISO 10319

Order Now and Secure Your Project’s Success

Don’t compromise on containment. Choose Geosynthetic Clay Liners Landfill Liner Material for unmatched sealing integrity and peace of mind.

📦 Bulk orders, custom dimensions, and technical support available.

📞 Contact us today to get your free quote or to speak with a geosynthetics specialist.

Parameter

Properties | Unit | Test Method | Frequency | Value |

GCL Property | ||||

Bentonite mass per unit area | g/m2 | ASTM D 5993 | 4000m2 | 3600g/m2 MARV |

Tensile Strength | kN/m | ASTM D 6768 | 4000m2 | 6kN/m MARV |

Peel Strength | N | ASTM D 4632 | 4000m2 | 65N MARV |

Hydraulic conductivity | cm/s | ASTM D 5887 | periodically | 5x10-2cm/sec MARV |

Shear Strength | kPa | ASTM D 6243 | periodically | 24 kPa Typical |

Geotextitle Property | ||||

g/m2 | ASTM D 5261 | 20,000m2 | 200 g/m2 MARV | |

Cap woven geotextile | g/m2 | ASTM D 5261 | 20,000m2 | 200 g/m2 MARV |

Bentonite property | ||||

Swell index | Kg | ASTM D 5890 | 50,000Kg | 24mI/2g MARV |

Moisture content | % | ASTM D 4643 | 50,000Kg | 12% max |

Fluid loss | ml | ASTM D 5891 | 50,000Kg | 18ml max |

Roll Dimensions | ||||

Width*Length | m | Typical | each roll | 5.8×30 |

Area Per Roll | m2 | Typical | each roll | 174 |

Packaged Weight | kg | Typical | each roll | 935 |

20GP loading | roll | Typical | each roll | 20 |

20GP loading Note: 1. Variation allowed 2%. 2.GCL Unit weight can be 5000g/m2.5500g/m2 .6000g/m2 3.Nonwoven Geotextile can be PP or PET material. | ||||

Geosynthetic Clay Liners Landfill Liner Material Features

Applications of Geosynthetic Clay Liners Landfill Liner Material