Road Soil Stabilizer Geocell Price

The demand for road soil stabilizer geocells has grown significantly in the past decade, driven by rapid infrastructure development and increasing awareness of cost-effective ground reinforcement solutions. Geocells, also known as cellular confinement systems, are three-dimensional polymeric grids used to stabilize soil and distribute loads efficiently.

According to recent industry analyses, the global geocell market size surpassed USD 500 million in 2024 and is projected to expand at a CAGR of over 7% through 2030. The growing need for durable and sustainable road bases, slope protection, and load-bearing applications in developing economies is fueling this demand. Consequently, **road soil stabilizer geocell price** trends have become a key focus for contractors and procurement managers across Asia, Africa, and the Middle East.

Global Market Overview of Road Soil Stabilizer Geocells

The demand for road soil stabilizer geocells has grown significantly in the past decade, driven by rapid infrastructure development and increasing awareness of cost-effective ground reinforcement solutions. Geocells, also known as cellular confinement systems, are three-dimensional polymeric grids used to stabilize soil and distribute loads efficiently.

According to recent industry analyses, the global geocell market size surpassed USD 500 million in 2024 and is projected to expand at a CAGR of over 7% through 2030. The growing need for durable and sustainable road bases, slope protection, and load-bearing applications in developing economies is fueling this demand. Consequently, **road soil stabilizer geocell price** trends have become a key focus for contractors and procurement managers across Asia, Africa, and the Middle East.

Understanding the Structure and Working Principle of Geocells

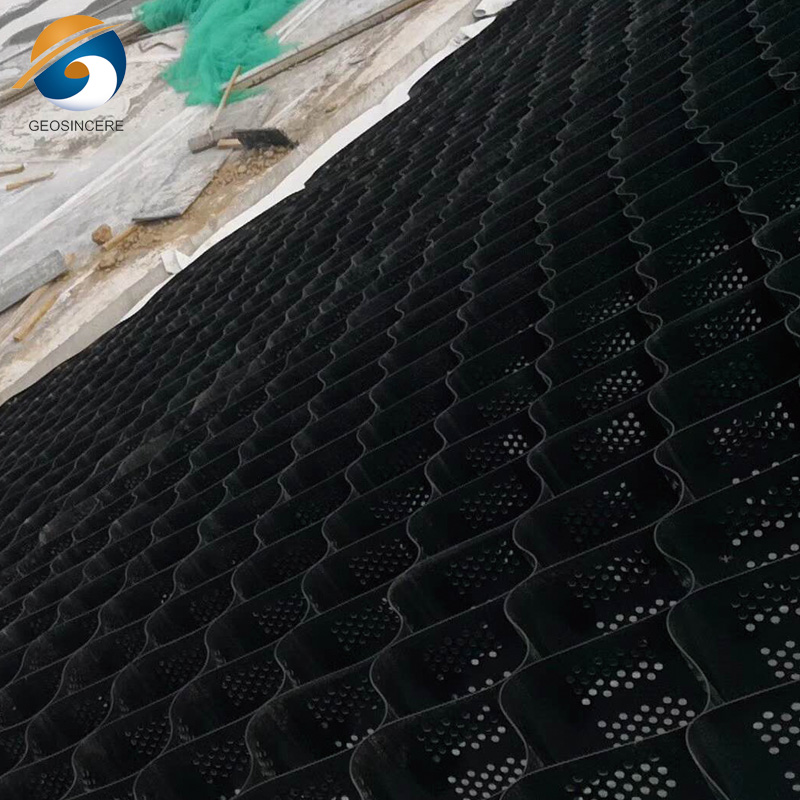

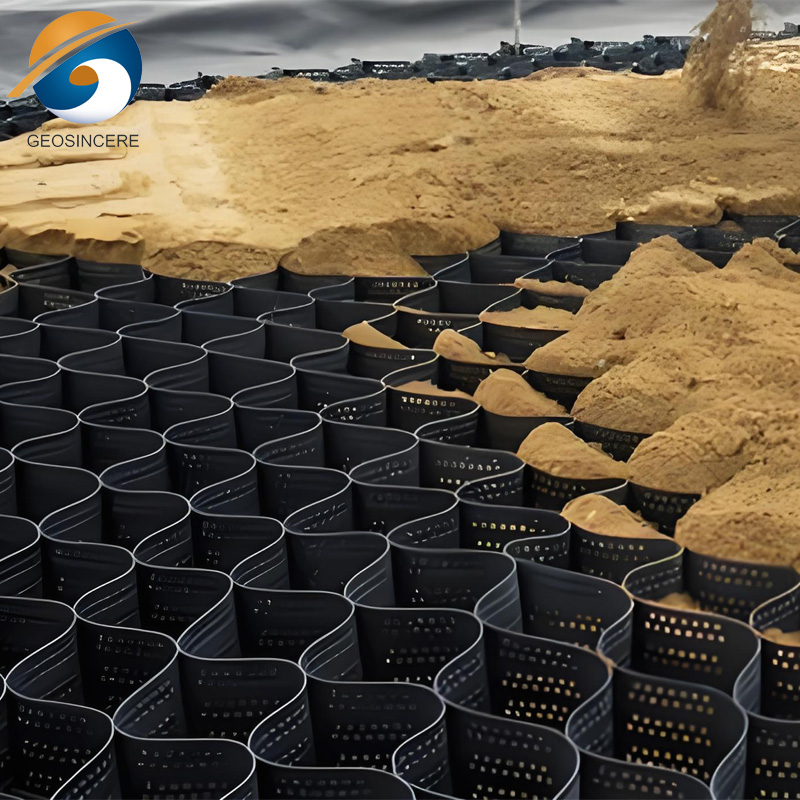

A **road soil stabilizer geocell** is typically made from high-density polyethylene (HDPE) or polypropylene (PP), featuring a honeycomb-like structure that expands on-site to confine soil, gravel, or sand. The interconnected cells create a semi-rigid structure that enhances soil bearing capacity, reduces erosion, and improves load distribution under heavy traffic.

Key properties include:

• Tensile strength: 14–20 kN/m (depending on thickness and resin quality)

• Cell height: 50–200 mm for different project requirements

• Seam strength: ≥ 140 N/mm (ultrasonic or hot-welded seams)

• Material type: HDPE or PP with UV and oxidation resistance

These technical parameters directly influence the **geocell price** and long-term performance in roadbed stabilization.

Manufacturing Process and Quality Standards

The manufacturing of **road soil stabilizer geocells** involves extrusion, perforation, and ultrasonic welding. The process begins with raw polymer granules melted and extruded into sheets. These sheets are perforated for better drainage and then ultrasonically welded at intervals to form the characteristic honeycomb structure.

Quality assurance plays a critical role in determining both performance and pricing. Compliance with ASTM D5199 (thickness), ASTM D4767 (tensile strength), and ISO 10319 (seam strength) ensures product reliability and international market acceptance. Manufacturers that invest in automated extrusion lines and precision welding equipment typically offer more consistent material strength and competitive **geocell pricing**.

Global Price Trends and Influencing Factors

The **road soil stabilizer geocell price** varies depending on raw material costs, cell height, wall thickness, and surface treatment. In 2025, average export prices range from USD 1.5 to USD 3.5 per square meter for standard HDPE geocells.

Major price determinants include:

• **Raw Material Costs:** HDPE resin prices fluctuate with global crude oil trends.

• **Manufacturing Efficiency:** Higher automation lowers production costs.

• **Product Specifications:** Thicker cell walls and higher tensile grades increase the price.

• **Export Logistics:** Shipping costs and packaging standards affect final CIF pricing.

In recent years, emerging markets have seen an upward trend in demand for reinforced geocells with improved load-bearing capabilities, which has slightly increased average **geocell price** levels.

Applications in Infrastructure and Environmental Projects

Road soil stabilizer geocells are widely applied across civil engineering, mining, and environmental sectors. Their most common uses include:

Road Base Reinforcement:** Enhancing the load capacity of weak soils under highways, access roads, and industrial pavements.

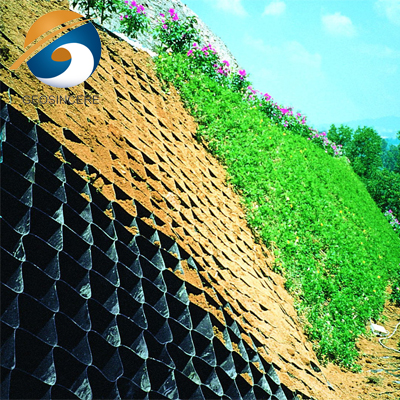

Slope and Channel Protection:** Preventing erosion and surface failure on embankments and drainage channels.

Retaining Wall Construction:** Providing structural confinement for backfill materials.

Load Support in Parking Areas and Railways:** Distributing weight evenly to minimize rutting and settlement.

Their lightweight nature and quick installation make them particularly attractive for remote and large-scale projects where concrete or asphalt reinforcement would be cost-prohibitive.

Market Dynamics and Buyer Insights

International buyers are becoming increasingly discerning when sourcing road soil stabilizer geocells, focusing on performance-to-price ratio, customization options, and delivery reliability.

Procurement teams in Asia and Africa prioritize affordability and long-term durability. Meanwhile, European and North American buyers emphasize compliance with ISO and ASTM standards, environmental certifications, and detailed product testing data.

Buyers also express concerns about inconsistent product quality from unverified suppliers. Transparent documentation—such as third-party test reports and batch traceability—can significantly enhance buyer confidence and justify premium pricing.

Emerging Trends and Future Outlook

As infrastructure projects increasingly integrate sustainability criteria, geocells made from recycled polymers or bio-based materials are gaining interest. Smart manufacturing technologies, including AI-driven extrusion monitoring and automated quality control, are improving production consistency and reducing waste.

Looking ahead, **road soil stabilizer geocell price** stability will depend on polymer market fluctuations, global logistics efficiency, and regional infrastructure funding policies. However, the long-term outlook remains optimistic due to governments’ continued investment in resilient and eco-friendly construction materials.

FAQs About Road Soil Stabilizer Geocell Price

Q1: What factors most influence road soil stabilizer geocell price?

A1: The main factors include raw material cost, wall thickness, cell height, and manufacturing quality. Transportation and packaging can also affect final export prices.

Q2: How long can HDPE geocells last in road stabilization projects?

A2: High-quality HDPE geocells can last over 20 years when properly installed and protected from prolonged UV exposure.

Q3: Are geocells suitable for use in wet or coastal areas?

A3: Yes. Their perforated design allows proper drainage, making them ideal for wet environments and coastal slope stabilization.

Q4: Can geocells be customized for specific road projects?

A4: Absolutely. Cell height, thickness, and panel dimensions can be tailored to meet different project requirements and loading conditions.

Professional Call to Action

For project contractors, engineers, and distributors seeking reliable and competitively priced solutions, **road soil stabilizer geocells** provide exceptional value in road base and soil reinforcement.

We supply detailed product specifications, technical data sheets, and free material samples upon request. Contact our engineering department today to receive a personalized quotation or professional consultation for your upcoming road construction or stabilization project.