Why Geomembranes Are Essential in Modern Mining Projects?

Geomembrane functions play a crucial function in the mining industry, which is resource-intensive and regularly accompanied through complicated environmental challenges. Whether the challenge entails metal, non-metal, or coal mining, it normally generates giant volumes of wastewater, tailings slurry, and acidic water—substances that pose vast infection dangers to soil, groundwater, ecosystems, and even human fitness if no longer excellent managed and contained.

As a result, a high-efficiency, stable, and long lasting anti-seepage gadget has end up a imperative thing in mining operations. In current years, geomembranes, as artificial polymer barrier materials, have won prominence for their terrific impermeability, chemical resistance, and building flexibility. These substances are now extensively utilized in tailings storage services (TSFs), answer ponds, heap leach pads, and leachate series ponds, appearing as the “invisible guardian” of contemporary mining projects.

This article explores the key blessings of geomembranes in mining applications, supported by means of real-world assignment cases, to assist engineers and procurement managers make knowledgeable cloth selections.

1. What Are Geomembranes? Definitions and Categories

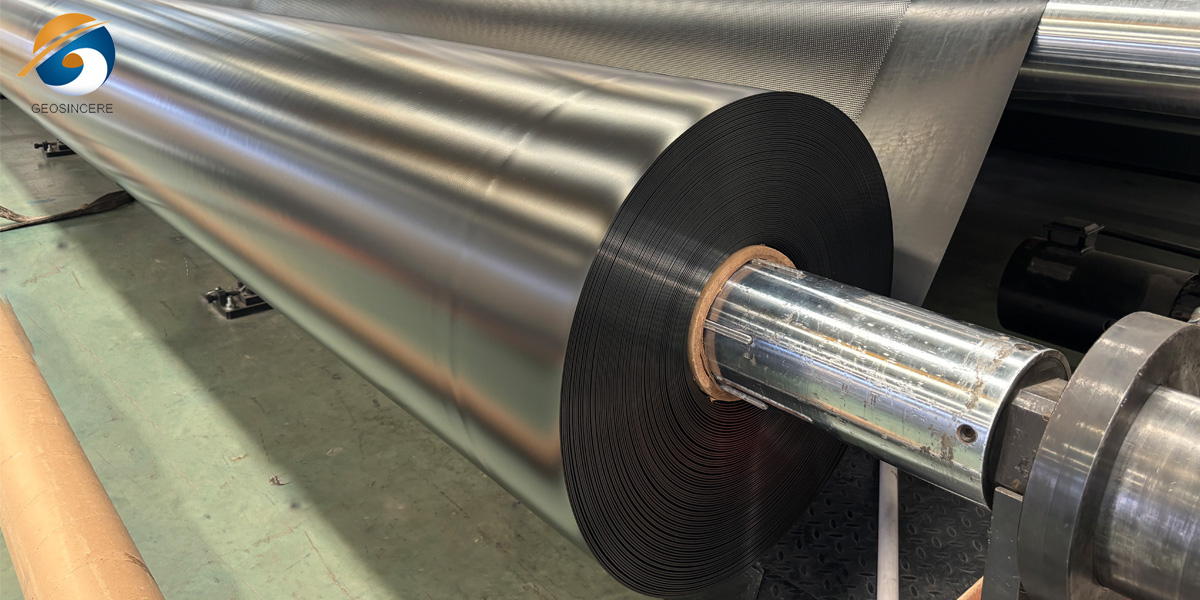

Geomembranes are skinny artificial membranes made from polymer resins such as HDPE, LLDPE,LDPE, PVC, or EVA, commonly manufactured thru blown movie or calendering processes. With a thickness ranging from 0.3 mm to three mm, their important feature is to forestall liquid and fuel migration by using forming a non-stop impermeable barrier.

Common Types of Geomembranes:

- HDPE Geomembrane (High-Density Polyethylene): High strength, awesome chemical resistance, and UV durability. Widely used in most mining applications.

- LLDPE Geomembrane (Linear Low-Density Polyethylene): Superior flexibility, perfect for uneven terrains and dynamic contract areas.

- LDPE (Low-density polyethylene): exact flexibility and puncture resistance, appropriate for complicated terrain, such as landfill slope anti-seepage, and chemical corrosion resistance.

- Composite Geomembranes: Laminated buildings combining geomembrane and geotextile, presenting each anti-seepage and reinforcement.

- PVC or EVA Membranes: Suitable for precise underground or personalized waterproofing applications.

2. Key Applications of Geomembranes in Mining Projects

2.1 Geomembranes for Tailings Storage Facilities (TSF)

TSFs are indispensable for storing waste slurry and residues. Given the excessive chance of contamination, HDPE geomembranes are used to forestall leaching of heavy metals and acidic liquids, making sure groundwater protection.

Benefits:

Minimizes seepage dangers and complies with international environmental requirements (e.g., ICMM)

Reduces long-term closure and remediation costs

2.2 Geomembranes for Heap Leach Pad Linings

In the extraction of gold, copper, and uranium, acidic or cyanide-based leaching options are employed. Geomembranes supply a sealed liner at the base and sides, stopping answer loss and environmental contamination.

Benefits:

Increases metallic recuperation charges (gold, silver, etc.)

Prevents cyanide leakage into the surrounding ecosystem

2.3 Geomembranes for Solution and Water Ponds

Intermediate ponds such as system answer ponds, stormwater ponds, and sedimentation basins might also incorporate hazardous liquids. HDPE or LLDPE geomembranes make sure long-term impermeability and structural integrity.

2.4 Geomembranes for Tailings Slurry Channels

Geomembrane-lined channels assist stop erosion of surrounding soils triggered via tailings slurry transport and prolong the lifespan of the slurry conveyance system. They additionally provide a reasonably-priced answer to decrease environmental impact, limit restore needs, and make certain safer, extra sustainable mining operations.

3. Six Key Advantages of Geomembranes in Mining Engineering

3.1 Outstanding Impermeability

Geomembranes have ultra-low permeability (typically <10⁻¹³ cm/s), tens of millions of instances decrease than compacted clay, supplying particularly superb liquid and gasoline containment.

3.2 High Chemical Resistance

Mining effluents regularly comprise heavy metals, acids, and natural solvents. HDPE geomembranes continue to be steady and long lasting even in harsh chemical environments such as cyanide or sulfuric acid solutions.

3.3 Efficient Installation & Cost-Effectiveness

Compared to ordinary compacted clay or concrete liners, geomembranes are lighter, less difficult to transport, quicker to weld, and require much less labor—especially appropriate for far off mining areas.

3.4 Excellent Terrain Adaptability

Flexible membranes like LLDPE and composites conform without difficulty to slopes, irregular surfaces, and undulating topography, making them perfect for mountainous or unstable terrains.

3.5 Long Service Life & Aging Resistance

Premium HDPE geomembranes can face up to long-term UV exposure, temperature fluctuations, and oxidation for 20+ years, making sure sturdiness in open-pit or long-life projects.

Durability: UV-resistant liners can stand up to years of direct daylight except losing structural integrity.

Cost Efficiency: Reduces the want for regularly occurring replacements or repairs, saving time and money.

Tip: For areas with robust daylight exposure, mix UV safety with thicker liners for top-quality durability.

3.6 Strong Thermal Welds Ensure Seamless Seepage Protection

Geomembranes are normally joined the use of thermal fusion welding, which creates molecular-level bonds between sheets for a non-stop and enormously impervious sealing system. This approach provides excessive tensile strength, splendid shear resistance, and long-term durability, making it particularly appropriate for large-scale functions such as tailings storage services and heap leach pads. Standardized welding methods considerably decorate the typical impermeability and structural integrity of the liner system.

4. Geomembrane Project Case Study

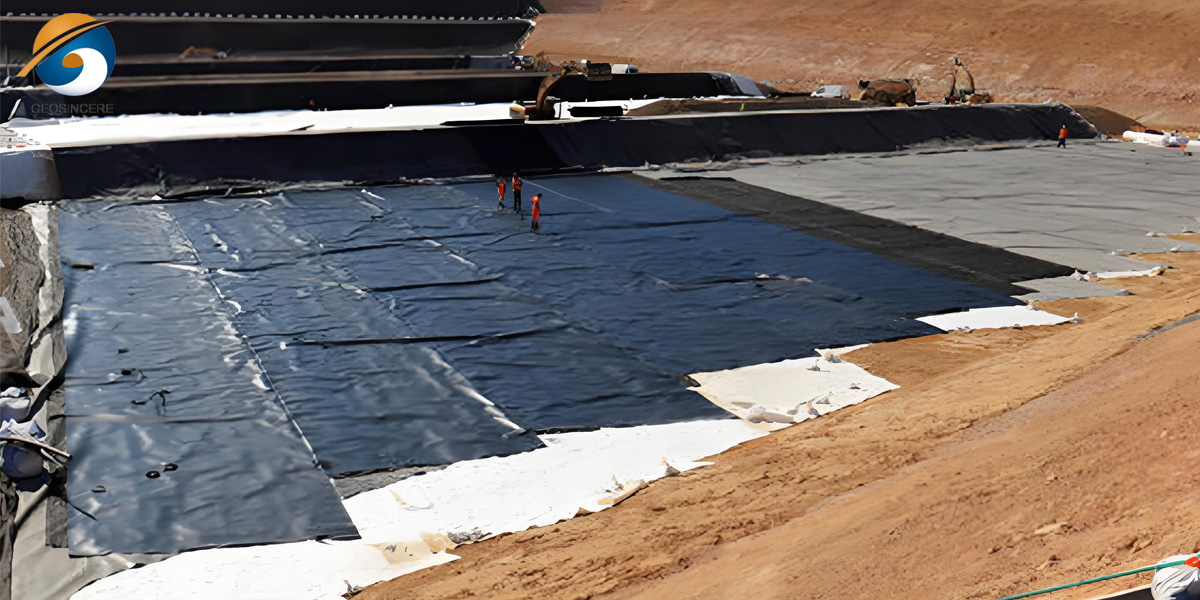

Geomembrane Project Case – Gold Mine TSF in Africa

Quantity: 1,820,000 m²

Geosino Our partner, a globally diagnosed gold producer and a member of the World Gold Council, adheres strictly to accountable mining standards and long-term neighborhood value.

After a complete evaluation of technical skills and product standards, Geosino Geomembrane used to be chosen as the liner provider for the client’s Tailings Storage Facility (TSF). We had been correctly appointed as the team dealer for all 5 of their mining operations throughout West Africa.

Geomembranes performed a integral function in making sure environmental compliance and operational efficiency. They furnished dependable containment of hazardous waste, contributing to the client’s dreams of sustainable and accountable mining.

5. Why Choose GEOSINCERE?

As a depended on provider of geosynthetic materials, GEOSINCERE adheres to the philosophy of “Quality First, Customer-Centric, Technology-Driven.” We are dedicated to handing over high-performance geomembrane options tailor-made to world mining demands.

5.1 Strict Raw Material Control – one hundred percent Virgin Resins

Our HDPE/LLDPE membranes are produced the usage of high-grade virgin polyethylene resins, making sure steady overall performance in tensile strength, elongation, and climate resistance—free of recycled content material or impurities.

5.2 Advanced Equipment & Automation

Our services are geared up with wholly automatic wide-width blown movie machines, laser-guided systems, and on line thickness control, enabling precise, consistent, and high-capacity production.

5.3 Full International Certifications

All merchandise comply with ISO, CE, GRT, and different international standards. Third-party lab reviews are additionally accessible upon request, assembly the entry necessities of giant global projects.

5.4 Comprehensive Technical Support

In addition to providing geomembranes, Geosino gives welding training, custom-made set up solutions, and on-site technical assistance—ensuring easy assignment shipping and decreased operational risk.

5.5 Customized Solutions

We provide bendy selections on membrane thickness, floor kind (smooth/textured), colour (black/white/green), and packaging, adapting to the special wishes of quite a number environments and regulatory requirements.

5.6 High-Volume Daily Output, Fast Response

With streamlined manufacturing structures and tremendous enterprise experience, Geosino produces 2–3 full 40ft containers of geomembranes per day, assembly the high-volume needs of foremost mining projects. Even for custom-made orders, we make sure fast manufacturing and dispatch to assist purchasers continue to be on agenda and keep away from venture delays.

6. Environmental Compliance & Corporate Responsibility

Choosing geomembranes is no longer simply a technical decision—it’s a declaration of dedication to environmental responsibility. In the face of tightening international environmental regulations, mining corporations that undertake geomembrane structures can enhance ESG ratings, minimize long-term liabilities, and decorate neighborhood and regulatory relations.

Conclusion: Sustainable Mining Begins with Seepage Control

As the world mining enterprise transitions towards greener, extra accountable practices, the great of containment structures performs an increasingly more imperative function in mission sustainability. Geomembranes—durable, efficient, and eco-friendly—are now the favored answer for environmental safety in mining engineering.

Choosing GEOSINCERE Geosynthetics potential deciding on a safer, greener, and greater reliable anti-seepage answer for your mining project.