How Do You Select the Right Dam Liners for Irrigation Systems?

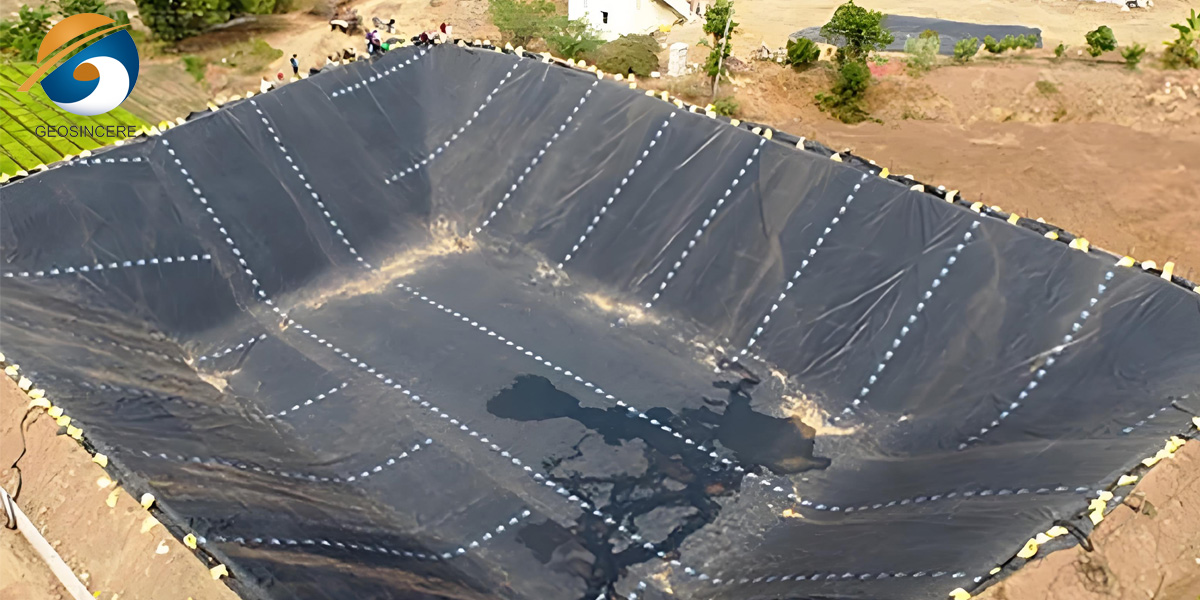

In agriculture, every drop of water translates to productivity and profit. With increasing droughts and water regulations, efficient storage isn't optional—it's essential. Dam liners (also known as geomembranes or reservoir liners) are the unsung heroes of water conservation, preventing seepage in irrigation ponds, storage tanks, canals, and reservoirs. But selecting the wrong liner can lead to costly failures, water loss, and environmental harm. This comprehensive guide cuts through the complexity, empowering you to choose the perfect dam liner for your unique irrigation needs.

1. Understanding Your Needs First When Selecting Dam Liners for Irrigation Systems

Water Type: Is it freshwater, recycled water, or chemical-treated?

Climate: Will the liner face extreme heat, UV exposure, or freezing?

Lifespan: Do you need 10 years of service or 30+?

Example: In sunny regions like Mexico, UV-resistant liners are non-negotiable.

2. Dam Liners for Irrigation Systems Material Deep Dive: Matching Performance to Need

Choosing the right geomembrane is critical. Here’s a detailed comparison:

2.1 HDPE (High-Density Polyethylene): The Long-Term Workhorse

Best For: Large-scale reservoirs (>1 acre), long-term projects (20-40+ years), high chemical exposure, UV-intense zones.

Pros: Unmatched durability, highest puncture/tear resistance (when thick), excellent UV and chemical resistance, lowest cost per decade of service.

Cons: Stiff and less flexible – challenging on uneven or complex shapes. Requires meticulous subgrade preparation. Seams must be professionally welded (extrusion or dual hot wedge). Prone to stress cracking if poorly installed or incompatible with site stresses.

Key Spec: Look for GRI-GM13 certification ensuring material quality and consistency. 1.0mm (40 mil) is a minimum; 1.5mm (60 mil) is standard for robustness; 2.0mm+ for heavy abuse.

2.2 LLDPE (Linear Low-Density Polyethylene): Flexibility & Conformability

Best For: Smaller ponds, intricate shapes (tight corners, rock features), moderate climates, shorter-term projects (10-20 years), budget-conscious needs.

Pros: Highly flexible and conformable – drapes easily over uneven ground and rocks. Easier DIY installation (seams often use tape). Good chemical resistance (verify NSF-61 if needed). Often more affordable upfront than HDPE.

Cons: Lower puncture resistance than HDPE. Significantly less UV resistance – lifespan plummets without high-quality UV stabilizers. Avoid in high-traffic or wildlife-heavy areas. Generally thinner gauge options.

Key Spec: Choose reinforced LLDPE for added strength. Insist on high UV stabilization (ask for test data). 0.75mm (30 mil) is absolute minimum; 1.0mm (40 mil) preferred.

2.3 EPDM (Ethylene Propylene Diene Monomer) Rubber: Frost King

Best For: Decorative ponds, frost-prone regions (excellent flexibility in cold), applications requiring high elongation (moving substrates), fish habitats.

Pros: Unbeatable flexibility and elasticity (-40°C to +120°C). Extremely resistant to weathering and ozone. Seams are reliably glued. Very fish/plant safe.

Cons: Lowest puncture/abrasion resistance of the three. Requires a protective non-woven geotextile underlay (min 300g/m²). Susceptible to damage by oils, some solvents, and UV if not properly formulated (ensure UV-resistant grade). Higher initial cost than polyethylenes.

Key Spec: Thickness usually 1.0mm (45 mil) or 1.14mm (45 mil). Look for high tensile strength ratings.

3. Dam Liners for Irrigation Systems Thickness Matters: The Armor Against Failure

Thickness (measured in millimeters or mils - 1mm = 40 mils) is your primary defense. Don’t undersize!

< 1.0mm (Under 40 mil): Risky! Only suitable for very temporary, seasonal water features with perfect subgrade (no rocks/roots). Highly susceptible to punctures, UV degradation, and installation damage. Not recommended for agriculture.

1.0–1.5 mm: Standard for most irrigation dams (balance of cost/durability).

1.5–2.0 mm: Heavy-duty for high-traffic sites or sharp substrates.

4. Dam Liners for Irrigation Systems Certifications: Your Guarantee of Quality & Safety

Never buy an uncertified liner. These are non-negotiable shields:

GRI-GM13 (Geosynthetic Institute - Standard Specification for HDPE): The gold standard for HDPE. Guarantees material composition, thickness consistency, tensile strength, tear resistance, puncture resistance, and stress crack resistance. Demand this for any HDPE.

FM Approvals (Fire Ratings): Necessary in wildfire-prone areas. Specific fire-retardant

HDPE formulations exist. Check local regulations.

UV Resistance Certification: Look for test data showing retained strength after accelerated UV exposure (e.g., ASTM D7238). Essential for HDPE and LLDPE longevity.

5. Installation Mastery: Ensuring Decades of Service

A perfect liner fails with poor installation. Follow these pro secrets:

Subgrade Perfection: Remove all sharp rocks, roots (especially woody ones), and debris. Compact the soil smoothly. This step prevents 80% of future punctures.

Underlay is Non-Negotiable: Always use a high-quality non-woven geotextile fabric (300-500g/m²) between the soil and liner. It cushions, protects, and helps distribute load. Double-layer on rocky sites.

Seam Integrity - The Weakest Link:

HDPE: Factory-fabricated panels are best. Field seams must be done by certified welders using extrusion or dual hot wedge methods, tested destructively (peel/shear) and non-destructively (air lance, spark test). Avoid tape for HDPE!

LLDPE: Factory seams ideal. Field seams often use specialized double-sided butyl or polyolefin tape applied meticulously to CLEAN surfaces under correct temperature.

EPDM: Use manufacturer-approved EPDM seam tape and primer. Weight seams during curing.

6. Dam Liners for Irrigation Systems Cost vs. Lifespan Value: The Smart Investment Equation

Don’t be fooled by the cheapest upfront price. Consider Total Cost of Ownership :

Cheap Thin LLDPE (0.5mm): $0.50-0.7/sq ft. Might last 3-5 years before leaks. High risk of water loss, crop damage, and expensive re-installation.

Quality 1.5mm HDPE with Underlay: $1.00-$1.50/sq ft. Lasts 25-40+ years. Reduces seepage by 98% or more. Minimal maintenance.

The Math: Saving 11,000m³/year (like the Chalco farm) at $0.50/m³ = $5,500/year saved. A $20,000 liner investment pays back in under 4 years, then delivers pure savings for decades. Factor in avoided crop losses from water stress – the value skyrockets.

7. Supplier Partnership: Your Lifeline for Success

Choosing the proper provider transcends a easy transaction; it is forging a indispensable partnership essential to your dam liner's long-term overall performance and your project's success. A authentic provider acts as your technical marketing consultant and dependable assist community at some stage in the liner's lifecycle. Scrutinize their Technical Expertise: Do they proactively ask detailed, site-specific questions about soil type, slope angles, neighborhood local weather extremes (temperature ranges, UV exposure), water chemistry, and supposed use (potable, agricultural, industrial)? This depth of inquiry demonstrates a authentic dedication to designing a solution, now not simply promoting a product. Investigate Material Provenance meticulously: Where is the uncooked resin sourced, and crucially, the place is the liner sheet really manufactured? Brands with installed reputations like GSE, Firestone, Agru, or Carlisle commonly implement rigorous, regular excellent manage (QC) protocols in the course of their international manufacturing processes, making sure cloth integrity. Local Support is non-negotiable for operational continuity: Can they furnish a listing of licensed installers with validated experience? Do they hold nearby inventory of imperative components like welding rods, restore kits, or fittings to decrease downtime? Is responsive, professional technical assist with ease handy throughout each set up and a long time of operation? Demand absolute Warranty Clarity: Understand exactly what is blanketed (e.g., fabric defects, seam failure, environmental stress cracking?), the particular exclusions, the length (20+ years is preferred for fantastic HDPE/EPDM), and the realistic steps of the claims process. Finally, discover their Sustainability ethos: Do they provide recycling packages for set up off-cuts or facilitate accountable end-of-life liner take-back? Partnering with a provider excelling in these areas mitigates chance and ensures you have a educated ally invested in your dam's enduring success.

8. Conclusion: Secure Your Water, Secure Your Future

Selecting the highest quality dam liner is a ways greater than a purchase; it is a profound strategic funding at once impacting your farm's operational resilience, environmental stewardship, and long-term profitability. Water safety is the bedrock of agricultural productivity. By fastidiously assessing your special web page environment, deciding on the most reliable cloth (HDPE or EPDM) and suitable thickness based totally on rigorous lifespan necessities and overall performance desires – in no way totally on upfront charge – and disturbing verifiable, licensed fine documentation (e.g., third-party trying out certificates), you lay the basis for success. This ought to be coupled with flawless set up carried out by using licensed professionals, using imperative shielding geotextile underlay and strong anchoring structures to guard in opposition to punctures and uplift. Crucially, partnering with a knowledgeable, supportive provider gives an integral lifeline. The end result is a high-integrity water storage asset engineered to supply dependable overall performance and large monetary dividends for decades. Viewing a top class HDPE or EPDM liner only as an rate is a integral error; it is, unequivocally, the foundational thing of sustainable water useful resource management. It actively protects your most fundamental asset towards catastrophic loss via seepage and evaporation, making sure each and every single treasured drop is correctly utilized to nourish your plants and maintain your enterprise. Consult impartial experts, prioritize demonstrated toughness and overall performance statistics over preliminary fee savings, and construct your critical water protection infrastructure with well-founded self belief for the future.

Contact us Now to discover the most secure and most good value dam liner answer for your Irrigation System