Why Choose HDPE Geomembrane Liner for Landfill Applications?

Why Choose HDPE Geomembrane Liner for Landfill Applications? The answer lies in its high-density polymer structure, low permeability, chemical resistance, and long-term durability, making it the primary engineered barrier material for modern landfill base and cap containment systems.

Technical Parameters and Specifications

When evaluating Why Choose HDPE Geomembrane Liner for Landfill Applications, procurement and engineering teams typically reference the following industry-accepted technical ranges based on common ASTM and ISO standards:

Material Type: High Density Polyethylene (HDPE)

Standard Thickness: 1.5 mm / 2.0 mm / 2.5 mm / 3.0 mm

Density: ≥ 0.940 g/cm³

Tensile Strength at Yield: ≥ 15 kN/m

Tensile Strength at Break: ≥ 27 kN/m

Elongation at Break: ≥ 700%

Puncture Resistance: ≥ 480 N (typical for ≥2.0 mm)

Carbon Black Content: 2.0–3.0%

Carbon Black Dispersion: Category 1–2

Standard OIT: ≥ 100 minutes

UV Resistance: Designed for long-term outdoor exposure

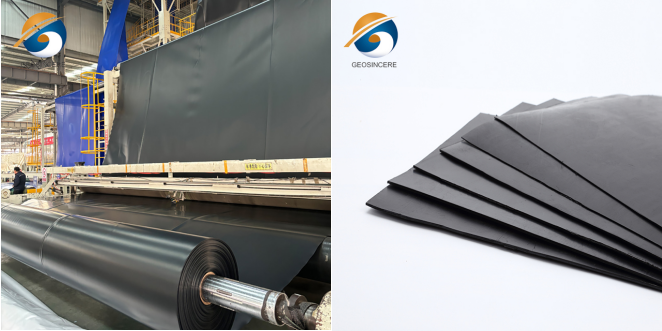

Structure and Material Composition

Understanding structure is central to explaining Why Choose HDPE Geomembrane Liner for Landfill Applications in engineered containment systems:

HDPE Polymer Matrix: Provides core impermeable barrier

Carbon Black Network: Ensures UV and weather resistance

Antioxidant Package: Slows thermal and oxidative aging

Optional Textured Surface: Improves slope friction stability

Homogeneous Sheet Structure: No woven paths for leakage

Manufacturing Process

From an engineering standpoint, Why Choose HDPE Geomembrane Liner for Landfill Applications is also linked to its controlled extrusion manufacturing process:

Virgin HDPE resin batching and additive dosing

High-temperature flat-die or blown-film extrusion

Online thickness monitoring and automatic gauge control

Surface texturing (if specified) via gas or embossing systems

Calendering and stress relief cooling

Non-destructive surface inspection

Mechanical and oxidative laboratory testing

Traceable roll labeling and packaging

Critical process controls include melt uniformity, additive dispersion, and thickness tolerance management.

Industry Comparison with Alternative Liners

A practical way to understand Why Choose HDPE Geomembrane Liner for Landfill Applications is through performance comparison with other liner materials.

| Property | HDPE Geomembrane | LLDPE Geomembrane | PVC Liner | Compacted Clay |

|---|---|---|---|---|

| Permeability | Very Low | Very Low | Low | Moderate |

| Chemical Resistance | Excellent | Good | Moderate | Variable |

| Stress Crack Resistance | High (with proper grade) | Very High | Low | Not applicable |

| Service Life | Long | Long | Medium | Design-dependent |

| Weld Integrity | High | High | Medium | Not weldable |

Application Scenarios

Project teams asking Why Choose HDPE Geomembrane Liner for Landfill Applications usually come from the following roles:

Distributors: Supply rolls for landfill and environmental projects

EPC Contractors: Execute landfill base liner and cap systems

Engineering Consultants: Specify barrier layers in design drawings

Waste Management Operators: Upgrade containment performance

Typical systems include landfill base liners, leachate ponds, closure caps, and secondary containment cells.

Core Pain Points and Engineering Solutions

Why Choose HDPE Geomembrane Liner for Landfill Applications becomes clear when mapped to real project pain points:

Leachate Leakage Risk: HDPE provides extremely low permeability barrier

Chemical Attack: Resistant to acids, alkalis, and organic compounds

Long-Term UV Exposure: Carbon black stabilization improves durability

Seam Failure Concerns: Thermal fusion welding creates homogeneous seams

Subgrade Settlement: High elongation accommodates differential movement

Risk Warnings and Mitigation Recommendations

Improper welding parameters may weaken seam strength

Sharp subgrade particles can cause puncture

Low-grade resin increases stress crack risk

Unverified suppliers may lack batch traceability

Mitigation measures include certified welders, cushion geotextiles, CQA testing, and third-party inspection protocols.

Procurement and Selection Guide

Confirm landfill class and regulatory requirements

Select thickness based on load and puncture analysis

Specify smooth or textured surface by slope design

Request full laboratory test reports

Verify antioxidant and OIT performance data

Check roll size versus site welding efficiency

Audit manufacturer quality control system

Plan CQA and onsite seam testing scope

Engineering Case Scenario

In a municipal solid waste landfill expansion project, a 2.0 mm HDPE liner system was installed over a compacted clay layer with protective nonwoven geotextile. Double-track hot wedge welding and vacuum box testing were applied. Post-installation electrical leak location surveys identified and repaired three minor defects before operation, resulting in a compliant containment base system.

Frequently Asked Questions

Q1: Why Choose HDPE Geomembrane Liner for Landfill Applications over clay?

A: Lower permeability and predictable performance.Q2: Typical landfill thickness?

A: Commonly 1.5–2.5 mm.Q3: Is HDPE chemically resistant?

A: Yes, to most landfill leachates.Q4: Can seams be tested?

A: Yes, by air channel and vacuum tests.Q5: Smooth or textured for landfill slopes?

A: Textured for higher friction.Q6: Expected service life?

A: Often several decades with proper design.Q7: Is third-party CQA required?

A: Common in regulated projects.Q8: Can it handle settlement?

A: Yes, with high elongation capacity.Q9: Welding method?

A: Hot wedge and extrusion welding.Q10: Storage precautions?

A: Avoid prolonged mechanical damage and heat.

Call to Action

For landfill projects requiring engineered barrier systems, request formal quotations, technical datasheets, and welding procedure guidelines for HDPE geomembrane liner materials to support design review and procurement evaluation.

E-E-A-T Author Credentials

Prepared by an environmental containment engineering team with more than 15 years of field and manufacturing experience in geomembrane liner systems, landfill barrier design support, and construction quality assurance practices.