Heavy Duty Pond Liner Textured Geomembrane

Manufacturing Process

The production of Heavy Duty Pond Liner Textured Geomembrane follows an industrial extrusion-based workflow:

Resin drying and gravimetric batching

Flat-die or blown-film extrusion under controlled temperature profiles

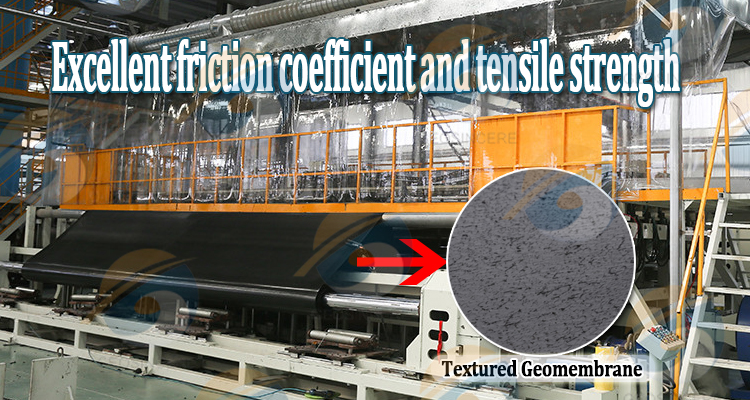

Inline texturing using nitrogen injection or embossing rollers

Calendering and thickness calibration

Controlled cooling and stress relaxation

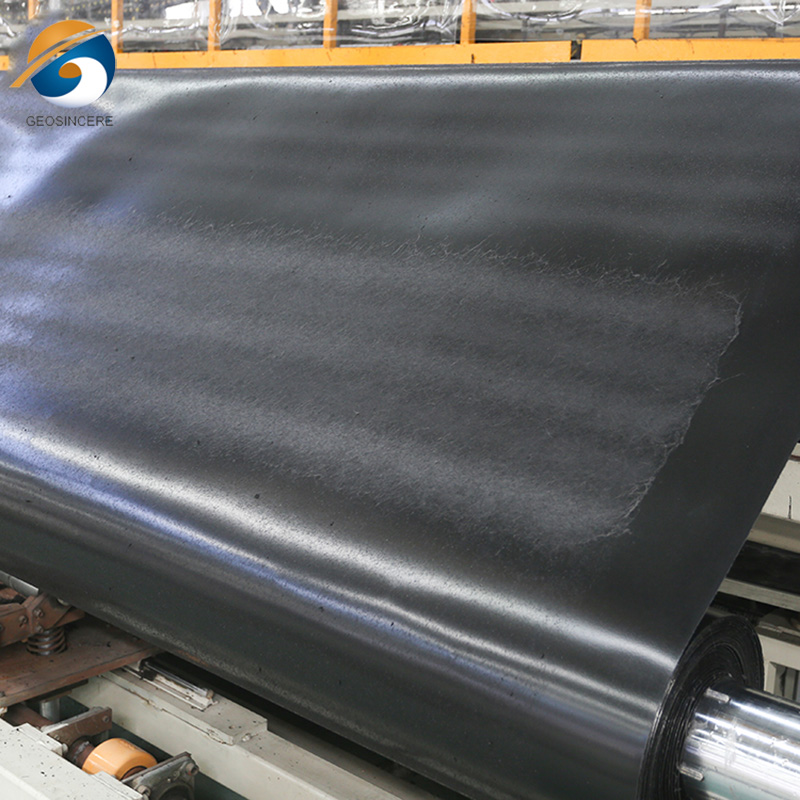

Automated winding and dimensional inspection

Laboratory testing (tensile, OIT, density, friction)

Key process controls include melt temperature stability, texture uniformity, and carbon black dispersion consistency.

Heavy Duty Pond Liner Textured Geomembrane is a high-strength polymeric impermeable liner with engineered surface texturing, designed to provide long-term seepage control and enhanced interface friction in ponds, reservoirs, and water containment systems under demanding engineering conditions.

Technical Parameters and Specifications

The following parameters represent commonly accepted industrial ranges for heavy-duty textured geomembranes used in engineered pond lining systems:

Raw Material: HDPE or LLDPE resin (virgin or controlled blend)

Nominal Thickness: 1.0 mm / 1.5 mm / 2.0 mm / 2.5 mm

Density: ≥ 0.94 g/cm³ (HDPE)

Tensile Strength at Yield: ≥ 15 MPa

Elongation at Break: ≥ 700%

Interface Friction Angle: 22°–30° (textured-to-soil)

Carbon Black Content: 2.0–3.0%

Oxidative Induction Time (OIT): ≥ 100 min (Std OIT)

Service Temperature Range: -40°C to +60°C

Structure and Material Composition

Heavy Duty Pond Liner Textured Geomembrane typically adopts a monolithic structure with engineered surface profiling:

Base Polymer Layer: High-density polyethylene matrix providing impermeability

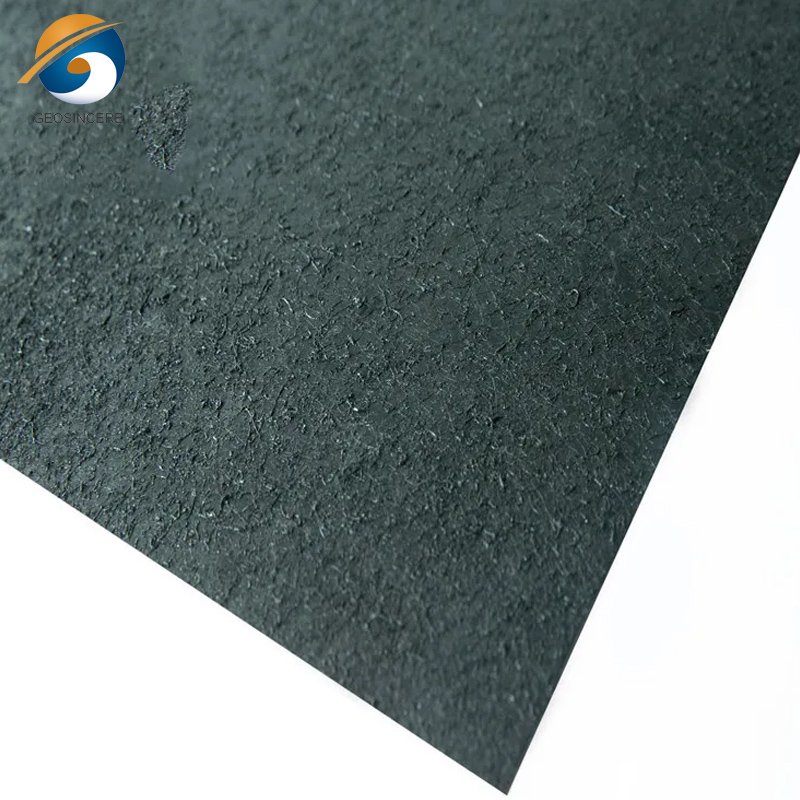

Textured Surface: Single-side or double-side asperities for friction enhancement

Carbon Black Dispersion: UV resistance and long-term durability

Thermal Stabilizers: Resistance to oxidative aging

Manufacturing Process

The production of Heavy Duty Pond Liner Textured Geomembrane follows an industrial extrusion-based workflow:

Resin drying and gravimetric batching

Flat-die or blown-film extrusion under controlled temperature profiles

Inline texturing using nitrogen injection or embossing rollers

Calendering and thickness calibration

Controlled cooling and stress relaxation

Automated winding and dimensional inspection

Laboratory testing (tensile, OIT, density, friction)

Key process controls include melt temperature stability, texture uniformity, and carbon black dispersion consistency.

Industry Comparison

| Material Type | Friction Performance | Durability | Installation Risk | Typical Use |

|---|---|---|---|---|

| Textured Geomembrane | High | Very High | Low (slopes) | Engineered ponds, steep slopes |

| Smooth Geomembrane | Low | Very High | High (slippage) | Flat-bottom reservoirs |

| EPDM Rubber Liner | Medium | Medium | Medium | Decorative ponds |

| PVC Liner | Low | Low | Medium | Temporary containment |

Application Scenarios

Heavy Duty Pond Liner Textured Geomembrane is widely specified by:

Distributors: Stocking standardized rolls for infrastructure projects

EPC Contractors: Design-build water and environmental systems

Engineering Firms: Slope stability–critical containment designs

Typical applications include irrigation reservoirs, aquaculture ponds, stormwater retention basins, leachate ponds, and industrial water containment.

Core Pain Points and Engineering Solutions

Slope Instability: Textured surfaces increase interface friction

Long-Term Leakage: High-density polymer ensures impermeability

UV Degradation: Carbon black stabilization extends service life

Thermal Cracking: Controlled resin formulation reduces stress cracking

Risk Warnings and Mitigation Recommendations

Improper use of Heavy Duty Pond Liner Textured Geomembrane may introduce risks:

Over-texturing may complicate welding quality

Incorrect thickness selection can lead to puncture risk

Poor subgrade preparation increases stress concentration

Mitigation includes certified welding technicians, subgrade smoothing, and project-specific thickness calculations.

Procurement and Selection Guide

Define pond geometry and maximum slope angle

Confirm chemical exposure and temperature range

Select appropriate thickness based on load analysis

Specify single or double textured surface

Request compliance test reports (ASTM / ISO)

Evaluate roll dimensions and logistics efficiency

Assess supplier quality control and traceability

Engineering Case Application

In a 50,000 m² agricultural reservoir project, Heavy Duty Pond Liner Textured Geomembrane (1.5 mm, double-sided) was installed on 3H:1V slopes. Interface shear testing confirmed a friction angle exceeding 26°, enabling stable lining without anchor trench enlargement. Post-installation leak detection reported zero defects after commissioning.

Frequently Asked Questions

Q1: Is textured geomembrane weldable?

A: Yes, with calibrated hot-wedge or extrusion welding.Q2: Single or double texture?

A: Depends on slope and interface requirements.Q3: Typical service life?

A: 20–30 years under standard exposure.Q4: Suitable for potable water?

A: Yes, when compliant with relevant standards.Q5: Minimum slope recommendation?

A: Commonly ≥ 2.5H:1V.Q6: UV exposure limits?

A: Designed for continuous outdoor exposure.Q7: Can it be repaired on-site?

A: Yes, via extrusion patch welding.Q8: Required subgrade?

A: Smooth, compacted, free of sharp objects.Q9: Roll width options?

A: Typically 5–8 m depending on equipment.Q10: Third-party testing available?

A: Commonly provided upon request.

Call to Action

For project-specific pricing, detailed technical datasheets, or engineering samples of Heavy Duty Pond Liner Textured Geomembrane, procurement teams and consultants are encouraged to request formal quotations and supporting documentation.

E-E-A-T Author Credentials

This article is prepared by a technical engineering team with over 15 years of experience in geomembrane manufacturing, quality assurance, and field application support across water containment, environmental, and infrastructure projects worldwide.