Polyester Non Woven Geotextile Drainage Filter Fabric

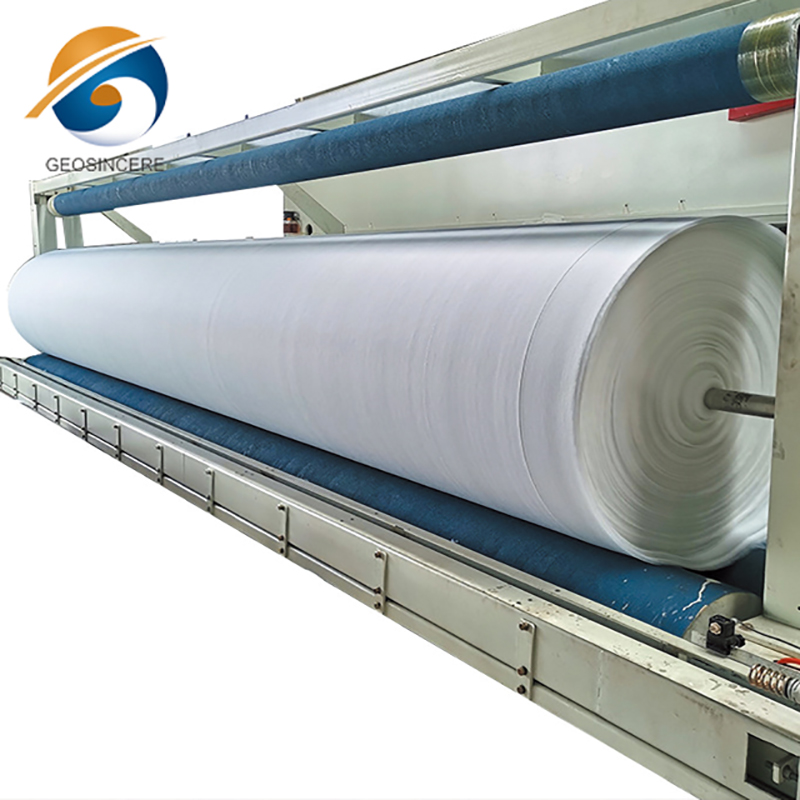

Manufacturing Process

The manufacturing process is highly controlled to ensure uniform filtration and mechanical stability.

Polyester fiber preparation and opening

Carding and web formation

Cross-lapping to achieve target weight and thickness

Needle punching for mechanical bonding

Heat setting and dimensional stabilization

Roll cutting and edge trimming

Quality inspection and batch traceability

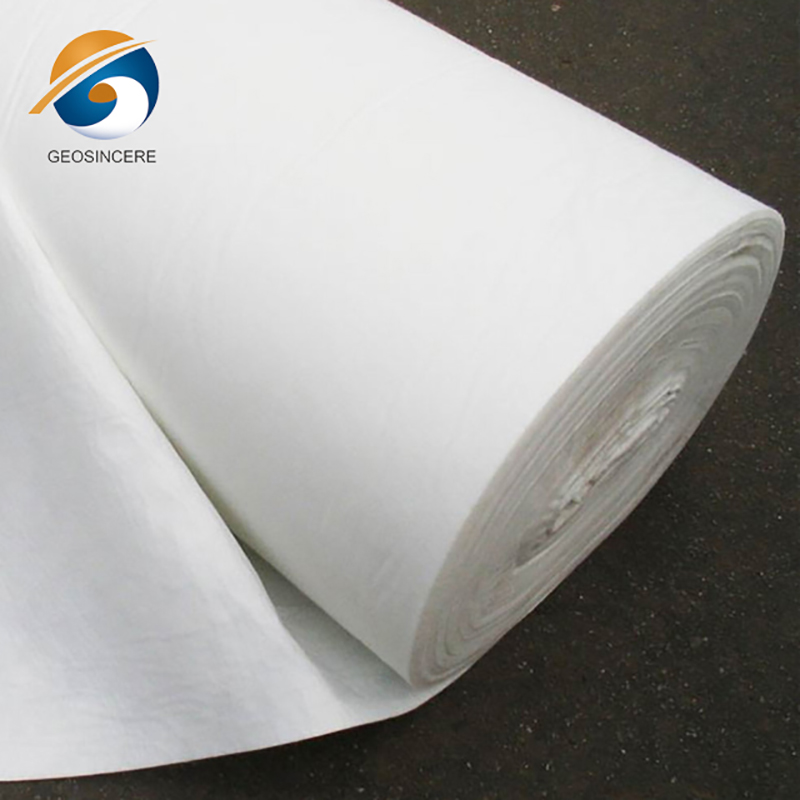

Product Definition

Polyester Non Woven Geotextile Drainage Filter Fabric is a needle-punched, permeable geosynthetic made from continuous or staple PET fibers, engineered to provide filtration, separation, drainage, and protection functions in civil, environmental, and infrastructure engineering projects.

Technical Parameters and Specifications

Polyester non woven geotextile drainage filter fabric is specified based on mechanical strength, hydraulic performance, and durability to ensure long-term performance in drainage systems.

Mass per unit area: 100–800 g/m²

Thickness (2 kPa): 0.8–4.5 mm

Tensile strength (MD/CD): 8–35 kN/m

Elongation at break: 40%–80%

CBR puncture resistance: 1.2–6.5 kN

Apparent opening size (AOS): 70–200 μm

Permittivity: ≥1.0 s⁻¹

Water flow rate: ≥80 L/m²/s

UV resistance (500 h): ≥70% strength retained

Service life: ≥50 years (buried conditions)

Structure and Material Composition

The functional performance of polyester non woven geotextile drainage filter fabric is determined by its internal fiber structure and bonding method.

Raw material: Virgin or high-grade recycled polyester (PET)

Fiber form: Staple fibers or continuous filaments

Bonding method: Mechanical needle punching

Pore structure: Three-dimensional interconnected voids

Surface characteristics: High friction coefficient for soil interaction

Manufacturing Process

The manufacturing process is highly controlled to ensure uniform filtration and mechanical stability.

Polyester fiber preparation and opening

Carding and web formation

Cross-lapping to achieve target weight and thickness

Needle punching for mechanical bonding

Heat setting and dimensional stabilization

Roll cutting and edge trimming

Quality inspection and batch traceability

Industry Comparison

| Parameter | Polyester Non Woven Geotextile | Polypropylene Non Woven | Woven Geotextile | Gravel Filter Layer |

|---|---|---|---|---|

| Filtration Efficiency | High | High | Moderate | Variable |

| Drainage Capacity | Excellent | Excellent | Limited | Moderate |

| Installation Speed | Fast | Fast | Moderate | Slow |

| Soil Compatibility | Very Good | Good | Moderate | Low |

| Cost Efficiency | High | High | Moderate | Low |

Application Scenarios

Polyester non woven geotextile drainage filter fabric is widely adopted across infrastructure and environmental engineering sectors.

Distributors: Drainage and geosynthetic product supply chains

EPC contractors: Road subgrade and railway drainage systems

Engineering consultants: Retaining walls and slope stabilization

Developers: Landfill leachate and stormwater management projects

Municipal authorities: Urban drainage and flood control works

Core Pain Points and Engineering Solutions

Soil clogging: Optimized pore size maintains filtration without blocking

Insufficient drainage: High permittivity ensures continuous water flow

Material degradation: Polyester offers strong chemical and biological resistance

Installation damage: High puncture resistance reduces construction risk

Risk Warnings and Mitigation

Improper specification or installation may compromise drainage performance.

Match AOS values to soil gradation to prevent piping

Avoid prolonged UV exposure before burial

Prevent excessive tension during installation

Ensure overlap lengths meet project specifications

Procurement and Selection Guide

Analyze soil particle size distribution

Define required filtration and drainage performance

Select appropriate mass per unit area

Verify tensile and puncture strength test reports

Confirm chemical compatibility with site conditions

Review roll dimensions and installation logistics

Request third-party quality certifications

Engineering Case Application

In a highway embankment drainage project, 400 g/m² polyester non woven geotextile drainage filter fabric was installed behind retaining structures and around perforated drainage pipes. The system effectively reduced pore water pressure, prevented soil migration, and has remained operational after six years of continuous service.

FAQ

Q1: What is the main function of this geotextile? A: Filtration and drainage.

Q2: Is polyester suitable for acidic soils? A: Yes, with good chemical resistance.

Q3: Can it replace sand filters? A: In most engineered drainage systems, yes.

Q4: What weight is commonly used for drainage? A: 200–400 g/m².

Q5: How is it installed? A: Rolled directly over prepared subgrades.

Q6: Can it be used underwater? A: Yes, with proper anchoring.

Q7: What is the typical roll width? A: 2–6 meters.

Q8: Is it resistant to biological degradation? A: Yes.

Q9: How long does it last underground? A: Over 50 years.

Q10: Does it require maintenance? A: No routine maintenance is required.

Call to Action

For detailed technical datasheets, laboratory test reports, project-specific recommendations, or bulk procurement quotations of polyester non woven geotextile drainage filter fabric, professional buyers and engineering teams are invited to request comprehensive technical support.

E-E-A-T Author Credentials

This article is authored by a geotechnical materials specialist with more than 15 years of experience in geosynthetics engineering, supporting EPC contractors, consultants, and international B2B procurement teams across infrastructure and environmental protection projects.