Driveway Grass Paver

Manufacturing Process

Manufacturing quality directly impacts structural performance and service life.

Raw material preparation (HDPE pellets or concrete mix)

Injection molding or high-pressure casting

Structural rib reinforcement forming

Controlled cooling or curing process

Dimensional accuracy inspection

Load-bearing and impact testing

Palletizing and batch traceability labeling

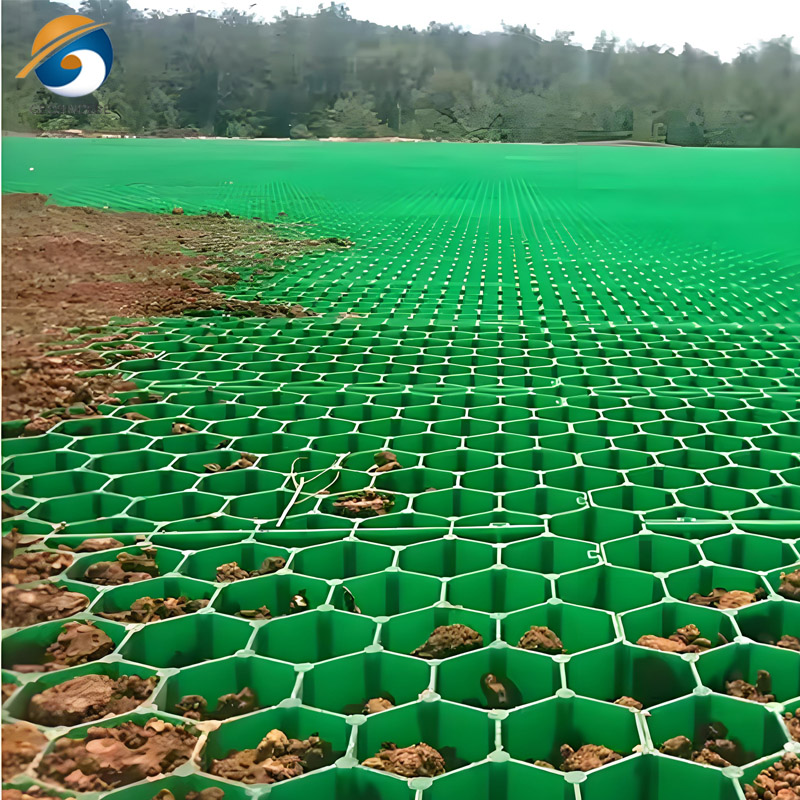

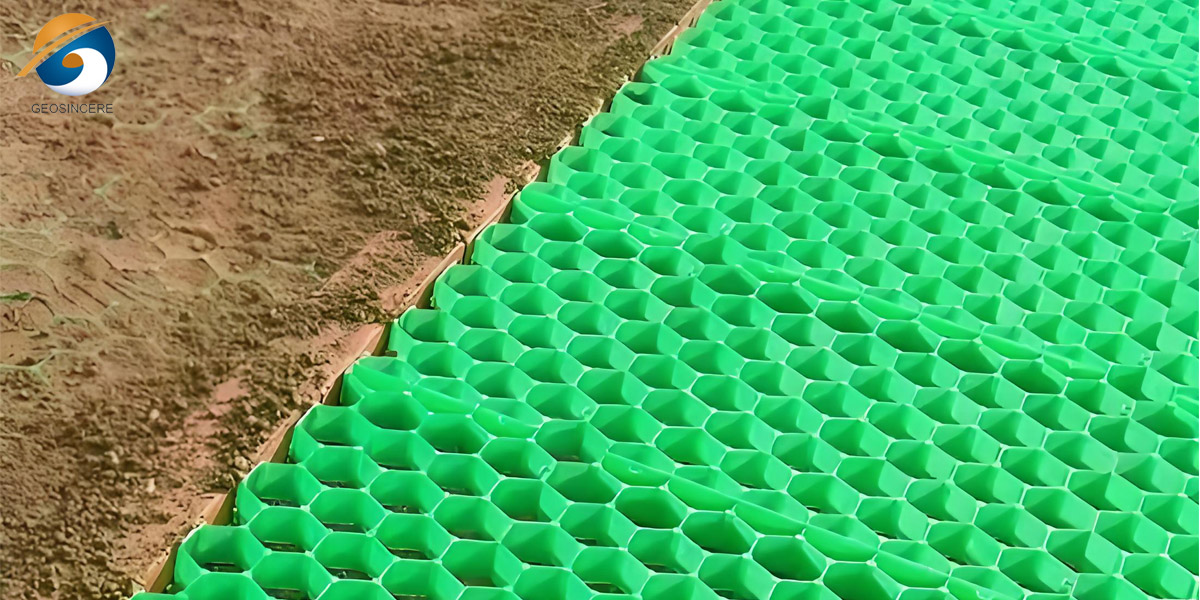

Product Definition

Driveway Grass Paver is a load-bearing permeable pavement system manufactured from high-strength polymer or concrete, designed to stabilize turf or gravel while supporting vehicular loads, enabling drainage, erosion control, and green infrastructure integration in driveway and access road applications.

Technical Parameters and Specifications

Engineering-grade driveway grass paver systems are specified based on load capacity, permeability, and environmental durability.

Standard module size: 400 × 400 mm / 500 × 500 mm

Thickness: 40–60 mm (polymer); 80–100 mm (concrete)

Compressive strength: ≥160 t/m² (polymer); ≥250 t/m² (concrete)

Material density (polymer): 0.95–1.05 g/cm³

Void ratio: 30%–50%

Water permeability coefficient: ≥1 × 10⁻² cm/s

Operating temperature: -30°C to +70°C

Service life: 20–25 years (polymer), 30+ years (concrete)

Structure and Material Composition

A driveway grass paver system combines structural support with vegetation accommodation.

Load-bearing frame: Interlocking grid structure

Material options: Recycled HDPE or precast concrete

Cell walls: Reinforced ribs for load distribution

Open cells: Designed for soil, grass, or gravel infill

Edge locking system: Prevents lateral movement under traffic

Manufacturing Process

Manufacturing quality directly impacts structural performance and service life.

Raw material preparation (HDPE pellets or concrete mix)

Injection molding or high-pressure casting

Structural rib reinforcement forming

Controlled cooling or curing process

Dimensional accuracy inspection

Load-bearing and impact testing

Palletizing and batch traceability labeling

Industry Comparison

| Parameter | Driveway Grass Paver | Concrete Pavement | Asphalt Pavement | Gravel Driveway |

|---|---|---|---|---|

| Permeability | Excellent | None | Low | High |

| Load Capacity | High | Very High | High | Low–Moderate |

| Environmental Impact | Low | High | High | Low |

| Maintenance | Low | Medium | Medium | High |

| Urban Heat Effect | Minimal | High | High | Low |

Application Scenarios

Driveway grass paver systems are widely specified in projects requiring both traffic access and environmental compliance.

Distributors: Residential driveway and villa projects

EPC contractors: Commercial parking access roads

Engineering firms: Municipal permeable pavement systems

Developers: Eco-parks, resorts, and green communities

Core Pain Points and Engineering Solutions

Surface rutting: Load-distribution grid prevents soil deformation

Poor drainage: Open-cell structure ensures rapid water infiltration

Heat accumulation: Vegetated surface reduces surface temperature

Maintenance complexity: Modular replacement minimizes repair cost

Risk Warnings and Mitigation

Incorrect design or installation can compromise system performance.

Ensure adequate sub-base compaction and thickness

Avoid underspecified paver thickness for heavy vehicles

Use suitable grass species or graded gravel infill

Prevent installation on unstable or saturated subgrades

Procurement and Selection Guide

Define vehicle load class and traffic frequency

Select material type (polymer or concrete)

Confirm permeability and void ratio requirements

Verify compressive strength test reports

Assess module interlocking performance

Review installation manuals and sub-base design

Confirm logistics, pallet size, and delivery timelines

Engineering Case Application

In a commercial office park project, a 3,200 m² driveway was constructed using polymer driveway grass paver modules over a 200 mm crushed stone sub-base. The system supported daily passenger vehicle traffic while maintaining effective stormwater infiltration and green surface coverage after four years of operation.

FAQ

Q1: Can driveway grass paver support cars? A: Yes, when properly specified.

Q2: Is it suitable for heavy trucks? A: Only with reinforced concrete models.

Q3: Does grass grow through the system? A: Yes, with proper soil infill.

Q4: What maintenance is required? A: Periodic grass trimming and inspection.

Q5: Is it frost-resistant? A: Yes, with proper sub-base drainage.

Q6: Can gravel be used instead of grass? A: Yes, for low-maintenance areas.

Q7: Typical installation time? A: Faster than poured concrete.

Q8: Does it meet permeable pavement standards? A: Yes, when designed correctly.

Q9: Can damaged modules be replaced? A: Yes, individually.

Q10: What is the design lifespan? A: 20–30 years depending on material.

Call to Action

For driveway grass paver technical datasheets, engineering samples, sub-base design recommendations, or project-specific quotations, procurement and engineering teams are invited to request detailed technical information.

E-E-A-T Author Credentials

This article is prepared by a civil and landscape engineering materials specialist with over 15 years of experience in permeable pavement systems, supporting EPC contractors, urban developers, and international B2B buyers in sustainable infrastructure projects.