HDPE Pond Liner for Sale

The global demand for HDPE pond liners has steadily increased over the past decade, driven by the rapid growth of aquaculture, landscape architecture, and water management projects. According to recent market reports, the geomembrane market is expected to surpass USD 3.8 billion by 2030, with HDPE products accounting for a significant share due to their durability and chemical resistance.

International buyers, especially in Asia-Pacific, North America, and the Middle East, are prioritizing liners that provide long-term performance, UV resistance, and ease of installation. HDPE pond liners have become a standard choice for fish farms, artificial lakes, irrigation systems, and wastewater containment projects.

Global Demand for HDPE Pond Liners

The global demand for HDPE pond liners has steadily increased over the past decade, driven by the rapid growth of aquaculture, landscape architecture, and water management projects. According to recent market reports, the geomembrane market is expected to surpass USD 3.8 billion by 2030, with HDPE products accounting for a significant share due to their durability and chemical resistance.

International buyers, especially in Asia-Pacific, North America, and the Middle East, are prioritizing liners that provide long-term performance, UV resistance, and ease of installation. HDPE pond liners have become a standard choice for fish farms, artificial lakes, irrigation systems, and wastewater containment projects.

Technical Specifications and Product Structure

HDPE pond liners for sale are engineered from high-density polyethylene with reinforced anti-UV properties and optional carbon black additives to resist photo-oxidation. Typical specifications include:

• Thickness range: 0.5mm–2.0mm

• Tensile strength: ≥25 MPa

• Elongation at break: ≥700%

• Water permeability: ≤1.0×10⁻¹³ cm/s

• Operating temperature: -40°C to 60°C

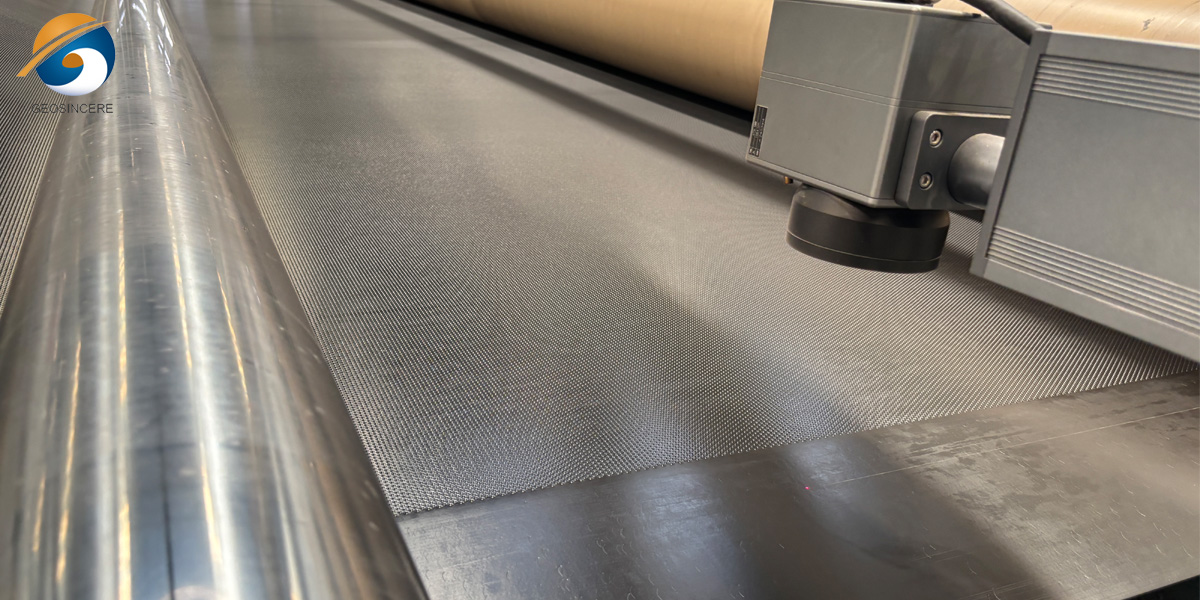

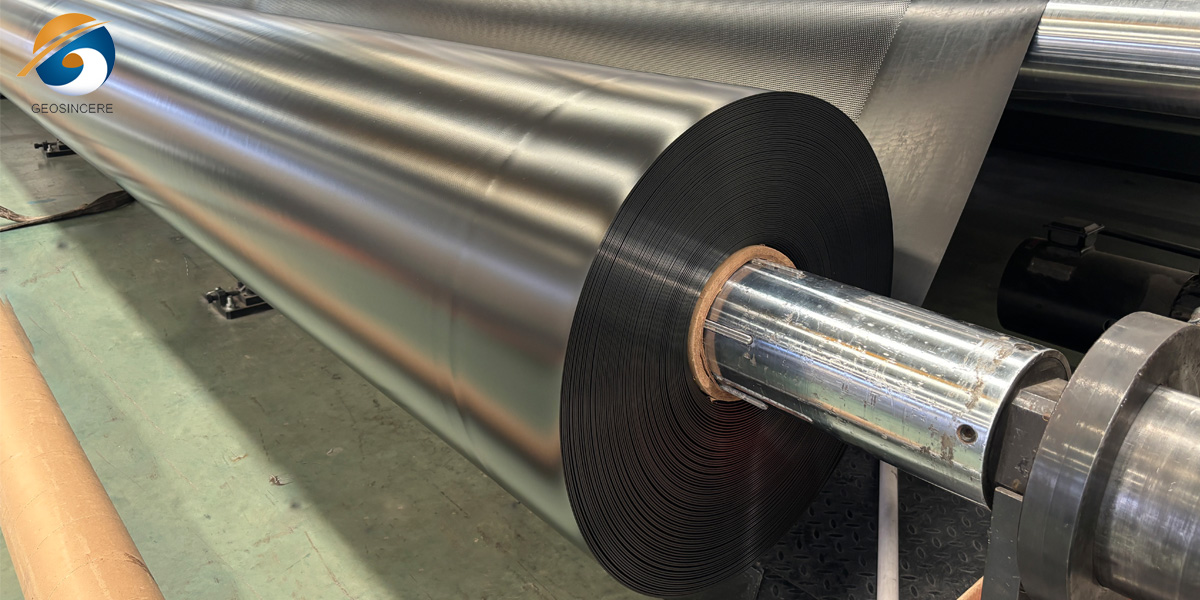

The product structure may include smooth or textured surfaces to enhance friction and stability when installed on slopes or irregular surfaces. Customizable options, such as prefabricated rolls and welded seams, are available for large-scale projects to minimize installation time and reduce labor costs.

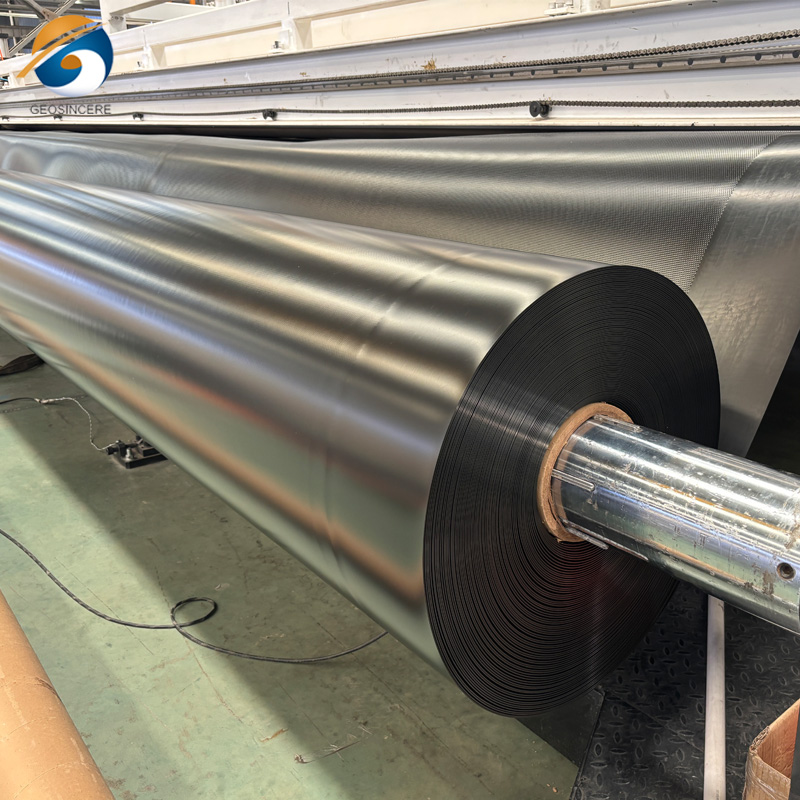

Manufacturing Process and Quality Assurance

HDPE pond liners are produced using advanced extrusion or co-extrusion techniques. High-quality raw materials are blended with UV stabilizers and antioxidants to extend lifespan. The extrusion process ensures uniform thickness and mechanical strength across the entire sheet.

Quality control includes tensile and tear strength tests, puncture resistance evaluation, and hydrostatic pressure testing. In-line inspection systems monitor thickness consistency, while laboratory tests ensure compliance with ASTM, GRI-GM13, or ISO standards. This rigorous quality assurance guarantees a reliable product capable of long-term water containment.

Applications in Aquaculture and Landscaping

HDPE pond liners are widely utilized in fish and shrimp farms, decorative ponds, golf course lakes, and irrigation reservoirs. In aquaculture, they prevent water seepage, maintain optimal water quality, and protect soil from contamination. For landscaping and recreational water features, HDPE liners provide aesthetically appealing, durable, and environmentally safe containment solutions.

Anti-UV properties are crucial for regions with intense sunlight, as prolonged exposure can accelerate polymer degradation. Properly installed liners can last 20 years or more with minimal maintenance, ensuring a low total cost of ownership for buyers.

Market Trends and Buyer Preferences

International buyers increasingly demand customization, environmental compliance, and verified certifications. ISO and ASTM compliance, coupled with third-party quality testing, have become essential factors for procurement decisions. Prefabricated panels and pre-welded rolls are gaining popularity due to faster installation and reduced onsite errors.

Cost efficiency, consistent product quality, and supplier transparency are top priorities. Buyers prefer suppliers offering comprehensive documentation, technical support, and flexible shipping options to ensure seamless integration into global projects.

Pricing Considerations for HDPE Pond Liners

The price of HDPE pond liners is influenced by raw material quality, thickness, UV resistance, and order volume. Typically, prices range from USD 1.5 to 4 per square meter, depending on specifications and shipping logistics. While cost is a factor, most international buyers prioritize durability and long-term performance over the lowest price, recognizing that substandard materials can lead to expensive repairs and operational downtime.

Frequently Asked Questions (FAQ)

1. What is the expected lifespan of an HDPE pond liner?

HDPE pond liners can last 15–20 years under proper installation and maintenance, even in harsh sunlight and varying environmental conditions.

2. Can the liner be customized for specific pond dimensions?

Yes. Custom sizes, prefabricated rolls, and welded seams are available to fit unique project layouts and minimize installation effort.

3. How does UV resistance enhance performance?

UV resistance prevents polymer degradation, maintaining flexibility, structural integrity, and water-tightness over extended exposure periods.

4. What documentation is provided for international procurement?

We supply test reports, quality certificates, and technical datasheets compliant with ASTM, ISO, and GRI standards to support project tendering and audits.

Professional Consultation and Sample Request

For engineers, contractors, and procurement managers seeking durable, high-performance water containment solutions, our HDPE pond liners for sale provide reliable and cost-effective results. Contact our technical team to request detailed specifications, quotations, and material samples tailored to your project requirements.

We are committed to delivering certified, long-lasting geomembrane solutions that enhance project efficiency and sustainability while ensuring global compliance and operational safety.