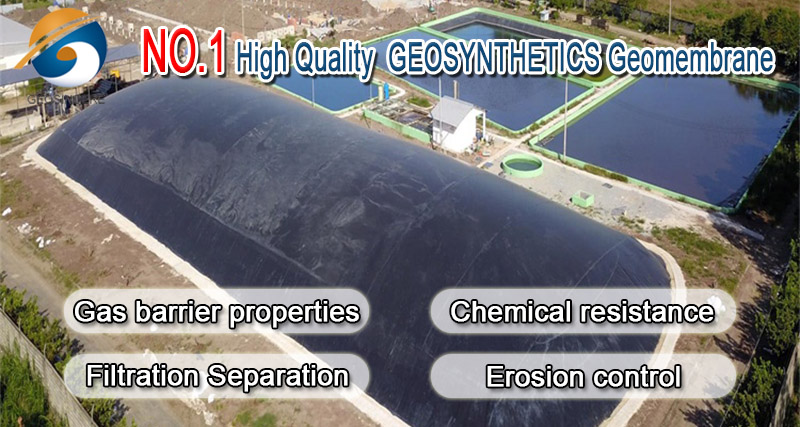

Geosynthetic Membrane Containment Liner for Biogas Digester

Manufacturing Process

Geosynthetic membranes used for biogas digesters are manufactured under controlled industrial processes to ensure uniform thickness, chemical stability, and gas containment performance.

Engineering Manufacturing Steps

Selection of virgin or controlled-grade polymer resin

Precision dosing of stabilizers, antioxidants, and UV inhibitors

High-temperature extrusion via flat-die or blown film equipment

Online thickness and surface inspection

Controlled cooling and tension-regulated winding

Batch sampling for mechanical and permeability testing

Critical Quality Control Points

Consistency of polymer melt flow index

Uniform dispersion of additives

Verification of gas-tightness and seam weldability

Product Definition

A geosynthetic membrane containment liner for biogas digester is an engineered polymeric barrier system designed to provide long-term impermeability, gas containment, and chemical resistance for anaerobic digestion facilities handling organic waste and biogas production.

Technical Parameters and Specifications

The following specifications reflect commonly adopted parameters for biogas digester liner systems. Actual values should be finalized according to digester size, feedstock composition, operating temperature, and applicable standards.

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Material Type | HDPE / LLDPE / fPP | ASTM / EN |

| Thickness | 1.0 mm – 2.5 mm | ASTM D5199 |

| Density (HDPE) | ≥ 0.94 g/cm³ | ASTM D1505 |

| Tensile Strength (Yield) | ≥ 15 MPa | ASTM D6693 |

| Elongation at Break | ≥ 600% | ASTM D6693 |

| Gas Permeability | Extremely Low | ASTM D1434 |

| Operating Temperature | -40°C to +60°C | Project Based |

Structure and Material Composition

A geosynthetic membrane containment liner for biogas digester typically forms part of a multi-layer containment and protection system:

Primary geomembrane liner – gas-tight and liquid-impermeable barrier

Secondary liner (optional) – redundancy for high-risk or large digesters

Protective geotextile layer – puncture and abrasion resistance

Subgrade preparation layer – compacted soil or concrete base

Gas collection interface – interface with biogas piping and fittings

Manufacturing Process

Geosynthetic membranes used for biogas digesters are manufactured under controlled industrial processes to ensure uniform thickness, chemical stability, and gas containment performance.

Engineering Manufacturing Steps

Selection of virgin or controlled-grade polymer resin

Precision dosing of stabilizers, antioxidants, and UV inhibitors

High-temperature extrusion via flat-die or blown film equipment

Online thickness and surface inspection

Controlled cooling and tension-regulated winding

Batch sampling for mechanical and permeability testing

Critical Quality Control Points

Consistency of polymer melt flow index

Uniform dispersion of additives

Verification of gas-tightness and seam weldability

Industry Comparison

| Material Type | Gas Tightness | Chemical Resistance | Flexibility | Typical Application |

|---|---|---|---|---|

| HDPE Geomembrane | Excellent | Excellent | Moderate | Large industrial digesters |

| LLDPE Geomembrane | Very Good | Very Good | High | Complex shapes, lagoons |

| fPP Geomembrane | Good | Good | High | Agricultural digesters |

| Concrete Tank | Variable | Limited | Low | Rigid digesters |

Application Scenarios

Geosynthetic membrane containment liners for biogas digesters are widely adopted by:

EPC contractors for renewable energy projects

Biogas plant developers and operators

Environmental engineering firms

Distributors and importers of geosynthetics

Core Pain Points and Engineering Solutions

1. Biogas Leakage

Solution: Selection of low-permeability geomembranes and qualified seam welding.

2. Chemical Degradation

Solution: Use of chemically resistant polymers suitable for organic acids and sulfides.

3. Thermal Expansion Stress

Solution: Flexible liner materials and allowance for thermal movement.

4. Installation Damage

Solution: Protective geotextile layers and strict installation protocols.

Risk Warnings and Mitigation Recommendations

Improper subgrade preparation may cause liner puncture

Unqualified welding can lead to long-term gas leakage

Inadequate UV protection accelerates aging

Ignoring chemical compatibility risks membrane degradation

Procurement and Selection Guide

Define digester type, volume, and operating conditions

Select appropriate membrane material and thickness

Confirm compliance with international standards

Review manufacturer quality control documentation

Request laboratory test reports and samples

Assess installation support and after-sales service

Engineering Application Case

In a large-scale agricultural biogas project, a 1.5 mm LLDPE geosynthetic membrane containment liner was installed in a covered lagoon digester of 60,000 m³ capacity. The system demonstrated stable gas containment and chemical resistance during continuous operation under mesophilic conditions.

Frequently Asked Questions (FAQ)

Q1: Which material is best for biogas digester liners?

A: HDPE or LLDPE depending on flexibility and scale.Q2: What thickness is commonly used?

A: Typically 1.0–2.0 mm.Q3: Can geomembranes withstand biogas chemicals?

A: Yes, when properly selected.Q4: How are seams tested?

A: Air pressure or vacuum testing.Q5: Is UV resistance required?

A: Yes, for exposed applications.Q6: Can liners be repaired on site?

A: Yes, using extrusion welding.Q7: What is the expected service life?

A: 20–40 years depending on conditions.Q8: Are double liners necessary?

A: For high-risk or large digesters.Q9: Is third-party inspection recommended?

A: Strongly recommended.Q10: What documents should be supplied?

A: QC reports, test certificates, and installation guidelines.

Request Quotation or Technical Documentation

For pricing, technical datasheets, material samples, or project-specific engineering support related to geosynthetic membrane containment liners for biogas digesters, formal procurement inquiries are encouraged.

Author Expertise and Industry Authority

This article is authored by a geosynthetics and renewable energy infrastructure specialist with over 15 years of experience in membrane manufacturing, biogas containment system design, and international EPC project execution.