HDPE Geomembrane Plastic Retention Pond Liner for Mining

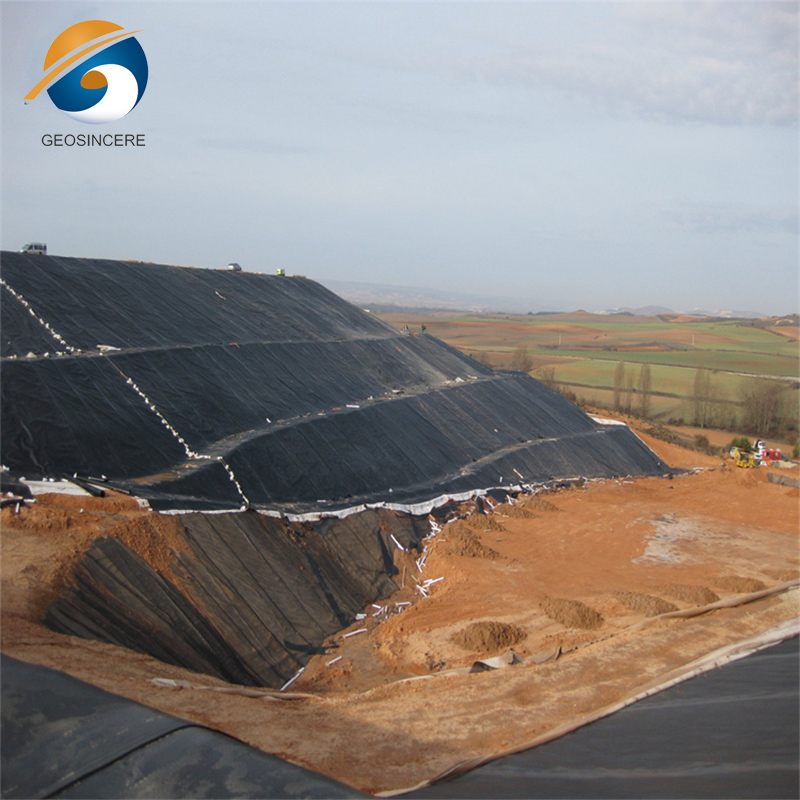

HDPE geomembrane plastic retention pond liners are commonly used in the mining industry for the construction of retention ponds. HDPE geomembrane liners are used to create a reliable and impermeable barrier that prevents the seepage of liquids, such as process water, tailings, leachate, and chemical solutions. They ensure that these liquids are contained within the retention ponds, reducing the risk of groundwater contamination and environmental impacts.

In mining operations, tailings are the waste materials generated from the mineral extraction process. HDPE geomembrane liners are often used to construct tailings ponds, which are designed to store and manage these waste materials. The liners prevent the seepage of liquids from the tailings, ensuring their safe containment and minimizing the risk of environmental contamination.

When it comes to effective liquid containment and environmental protection in mining operations, HDPE geomembrane plastic retention pond liners for mining are the industry gold standard. These high-density polyethylene (HDPE) liners offer superior strength, chemical resistance, and long-term performance in harsh mining environments, making them essential for tailings management, heap leach pads, and retention ponds.

Why Choose HDPE Geomembrane Plastic Retention Pond Liner for Mining?

1. Unmatched Chemical and UV Resistance

Mining processes often involve the use of aggressive chemicals and prolonged exposure to sunlight. A HDPE geomembrane plastic retention pond liner for mining provides outstanding resistance to UV radiation and harsh chemicals, ensuring structural integrity over decades.

2. Superior Puncture and Tear Resistance

Heavy machinery and rugged substrates can easily damage inferior liners. An HDPE geomembrane plastic retention pond liner for mining is engineered with high tensile strength and puncture resistance, making it ideal for the tough conditions of mining sites.

3. Leak-Proof Environmental Protection

Containment failure can lead to catastrophic environmental damage and regulatory penalties. With a HDPE geomembrane plastic retention pond liner for mining, operators can trust in a waterproof barrier that safeguards both natural resources and operational compliance.

4. Long-Term Cost Savings

Investing in a durable HDPE geomembrane plastic retention pond liner for mining reduces long-term maintenance costs, minimizes downtime, and lowers the risk of environmental remediation expenses.

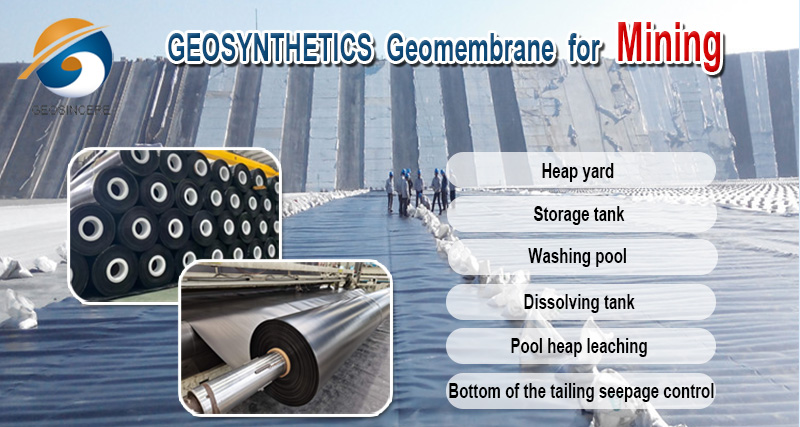

Common Applications in Mining Operations

A HDPE geomembrane plastic retention pond liner for mining is suitable for a wide range of critical containment systems, including:

Retention ponds

Heap leach pads

Tailings dams

Evaporation ponds

Process water reservoirs

Stormwater containment basins

These liners are specifically designed to handle the dynamic and high-risk conditions of modern mining activities.

Technical Features of HDPE Geomembrane Plastic Retention Pond Liner for Mining

Material: High-Density Polyethylene (HDPE)

Thickness: 0.75mm to 3.0mm (customizable)

Surface: Smooth or textured

Color: Black, white, or dual

Lifespan: 20+ years in exposed conditions

Certifications: ISO 9001, ASTM, GRI-GM13 compliant

Every HDPE geomembrane plastic retention pond liner for mining is subjected to rigorous quality control and laboratory testing to ensure durability and consistency.

How to Choose the Right HDPE Liner for Your Mining Project

When selecting a HDPE geomembrane plastic retention pond liner for mining, consider the following:

Chemical exposure levels

Temperature range

Installation environment (exposed or buried)

Subgrade conditions

Expected lifespan

Consulting with a professional liner manufacturer ensures you get a customized solution tailored to your mining operation’s specific needs.

Installation & Support Services

Proper installation is key to the effectiveness of any HDPE geomembrane plastic retention pond liner for mining. Leading suppliers offer full-service installation teams equipped with advanced welding equipment and trained technicians. This ensures tight seams, zero leaks, and fast deployment across any terrain.

Look for manufacturers that provide:

On-site supervision

Quality assurance testing (spark testing, air pressure testing)

Seaming certifications

Post-installation support

Why Leading Mining Companies Trust HDPE Geomembrane Liners

With rising environmental regulations and increasing operational risks, mining companies worldwide are turning to HDPE geomembrane plastic retention pond liners for mining to secure their operations and protect surrounding ecosystems.

Whether operating in copper, gold, coal, or lithium mining, these liners provide peace of mind, lower operational risk, and deliver consistent performance.

Get a Free Quote Today

Ready to enhance your mine’s containment strategy? Choose the most trusted solution: the HDPE geomembrane plastic retention pond liner for mining.

We offer:

Competitive pricing

Custom sizes and thicknesses

Fast global shipping

Expert technical support

Contact us today to request a free quote and see why our HDPE geomembrane plastic retention pond liner for mining is the top choice for mining professionals around the world.

Durability and Longevity, HDPE geomembrane liners are designed to be highly durable and long-lasting, even in rugged mining environments. They can withstand abrasion, punctures, and chemical exposures, ensuring the integrity of the containment system over the operational lifespan of the mining facility.

Environmental Protection, The use of HDPE geomembrane liners in mining applications helps protect the environment by preventing the release of potentially harmful substances into the surrounding soil, surface water, and groundwater. They play a crucial role in minimizing the impact of mining operations on ecosystems and nearby communities.HDPE geomembrane liners are particularly important in the management of tailings, which are the waste materials generated from mining processes. The liners prevent the seepage of tailings fluids into the environment, protecting water resources and reducing the risk of contamination.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Geomembrane Plastic Retention Pond Liner for Mining Features

Excellent Chemical Resistance.

Outstanding Stress Crack Capacity.

Lowest Permeability.

Excellent UV Resistance.

Stable Low Temperature Embrittlement Resistance.

Proven Performance.

Fast Deployment.

Easy Transportation.

ISO9001 Certificated Geomembrane Factory.

Meet or Exceed All Aspects of GRI GM13.

Complete Width and Thickness Specifications.

Competitive Factory Price.

ODM/OEM are Available.

Applications of HDPE Geomembrane Plastic Retention Pond Liner

HDPE geomembrane plastic retention pond liners have a wide range of applications beyond mining. Here are some common applications:

Agriculture and Aquaculture: HDPE geomembrane liners are used in agricultural applications such as lining irrigation ponds, reservoirs, and canals. They help prevent water seepage, ensure efficient water storage, and minimize water loss. In aquaculture, they are used in fish ponds, shrimp ponds, and hatcheries to maintain water levels and prevent seepage.

Landfills and Waste Containment: HDPE geomembrane liners are extensively used in landfill construction to contain and prevent the migration of contaminants from waste materials into the surrounding environment. They act as a barrier to protect soil and groundwater from pollution. These liners are also used in hazardous waste storage facilities and containment areas.

Water and Wastewater Treatment: HDPE geomembrane liners are employed in water and wastewater treatment facilities to line containment basins, lagoons, and ponds. They prevent the seepage of treated water or wastewater into the surrounding environment and help maintain the desired water levels.

Oil and Gas Industry: HDPE geomembrane liners are used in the oil and gas industry for various applications, including lining evaporation ponds, storage tanks, secondary containment systems, and oil spill containment areas. They help prevent leaks and spills from contaminating the soil and groundwater.

Environmental Remediation: HDPE geomembrane liners are used in environmental remediation projects to contain and control contaminated soil, groundwater, and hazardous substances. They aid in the cleanup and restoration of contaminated sites by preventing the migration of contaminants.

Stormwater Management: HDPE geomembrane liners are employed in stormwater management systems, including retention ponds, detention basins, and stormwater treatment facilities. They help regulate the flow of stormwater, prevent erosion, and reduce the risk of pollutants entering water bodies.

Industrial Applications: HDPE geomembrane liners find application in various industrial sectors, such as chemical storage facilities, mining operations, power plants, and manufacturing sites. They are used for containment, leak prevention, and environmental protection in these industrial settings.

These are just a few examples of the applications of HDPE geomembrane plastic retention pond liners. Their versatility, durability, and impermeability make them a valuable solution in a wide range of industries where containment, environmental protection, and water management are critical.