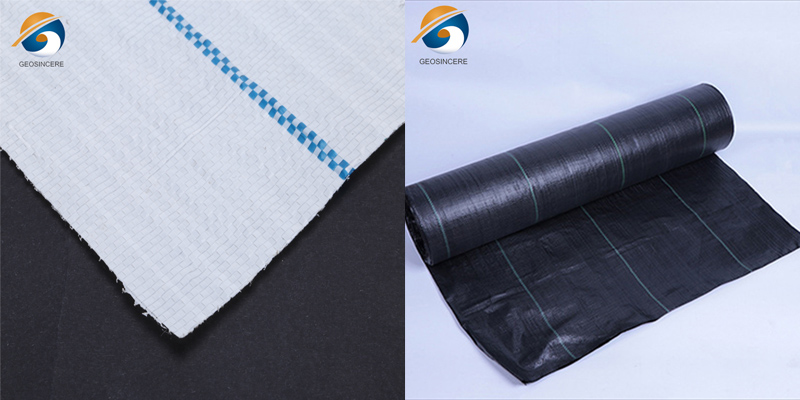

PP Woven Polypropylene Geotextile Separation Fabric

PP woven polypropylene geotextile separation fabric is becoming an essential material in modern infrastructure, driven by increasing global investment in transportation, water management and large-scale construction projects. With countries rapidly expanding highways, railways and industrial zones, the demand for cost-efficient ground stabilization and long-term soil separation solutions continues to rise. In regions such as Southeast Asia, the Middle East and Africa, where soil conditions are complex, this material is valued for its durability, tensile strength and reliable filtration capabilities.

Over the past five years, the global geotextile market has grown at an annual rate of 6%–8%, with woven polypropylene products accounting for a significant proportion due to their superior mechanical strength and competitive pricing. As governments implement stricter standards for soil protection and roadway longevity, PP woven geotextile separation fabric is anticipated to maintain steady growth through 2030.

Global Demand Rising for PP Woven Polypropylene Geotextile Separation Fabric

PP woven polypropylene geotextile separation fabric is becoming an essential material in modern infrastructure, driven by increasing global investment in transportation, water management and large-scale construction projects. With countries rapidly expanding highways, railways and industrial zones, the demand for cost-efficient ground stabilization and long-term soil separation solutions continues to rise. In regions such as Southeast Asia, the Middle East and Africa, where soil conditions are complex, this material is valued for its durability, tensile strength and reliable filtration capabilities.

Over the past five years, the global geotextile market has grown at an annual rate of 6%–8%, with woven polypropylene products accounting for a significant proportion due to their superior mechanical strength and competitive pricing. As governments implement stricter standards for soil protection and roadway longevity, PP woven geotextile separation fabric is anticipated to maintain steady growth through 2030.

Industry Background and Market Trends

Infrastructure spending is the primary driver behind the increasing adoption of PP woven polypropylene geotextile separation fabric. Developing economies continue to prioritize highway reinforcement, rural road upgrades and flood-control systems. Meanwhile, mature markets in North America and Europe rely heavily on geotextiles for railway ballast stabilization, erosion control and pavement lifespan extension.

Key trends shaping the market include rising interest in long-life materials, improved standards for ground stabilization, and sustainable construction practices. Manufacturers are also shifting toward high-flatness weaving techniques and heavier-duty polypropylene tapes to enhance tensile performance while maintaining cost efficiency.

Technical Specifications and Performance Features

The performance of PP woven polypropylene geotextile separation fabric is defined by several core parameters that determine its suitability for separation, reinforcement and filtration applications. Typical technical specifications include:

Tensile Strength

Standard products offer tensile strength ranging from 8–80 kN/m, depending on fabric weight and weave density. This high strength-to-weight ratio ensures structural stability under various loading conditions, particularly in soft soil environments.

Apparent Opening Size (AOS)

The fabric’s controlled pore size allows efficient filtration while preventing soil mixing. AOS values typically range from 0.1 to 0.6 mm, enabling effective separation between subgrade and aggregate layers.

Permeability

While primarily designed for separation, PP woven geotextile maintains adequate water flow to prevent pore pressure build-up. Permeability rates vary based on weaving structure and tape width.

UV and Chemical Resistance

Polypropylene provides inherent resistance to soil chemicals, salts and moderate UV exposure, making the fabric suitable for long-term outdoor use when properly covered by soil or aggregates.

Product Structure and Manufacturing Process

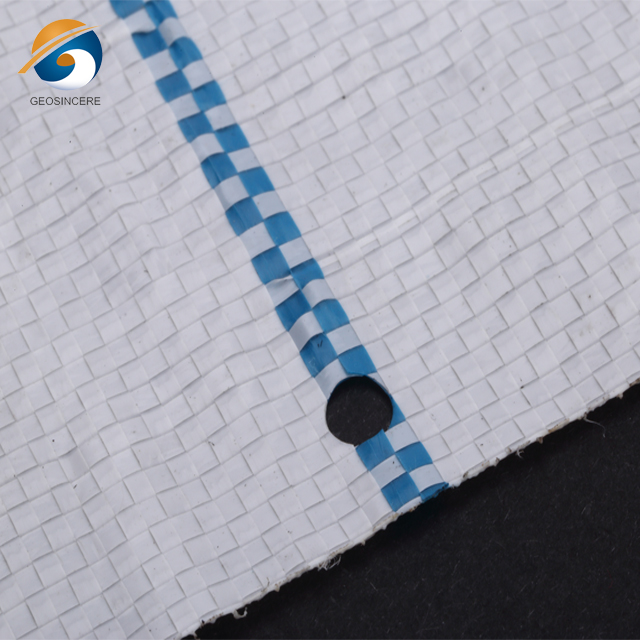

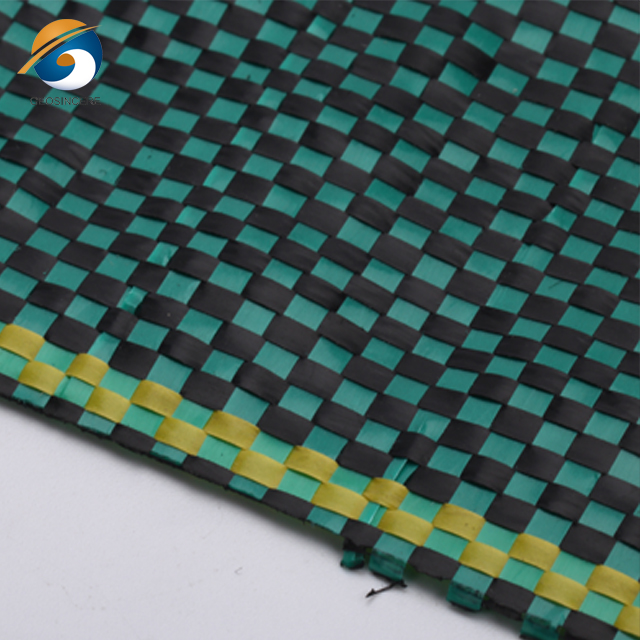

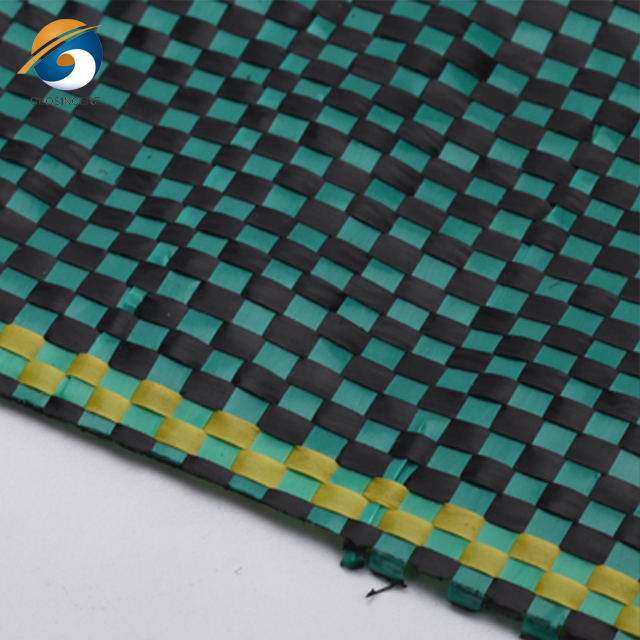

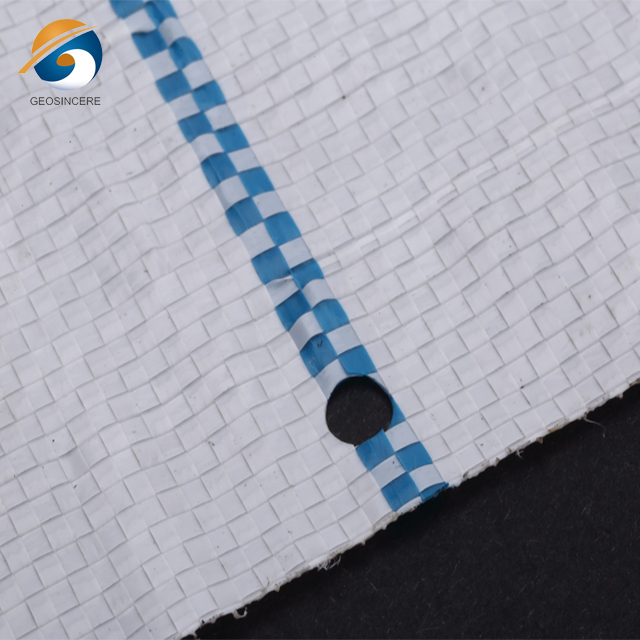

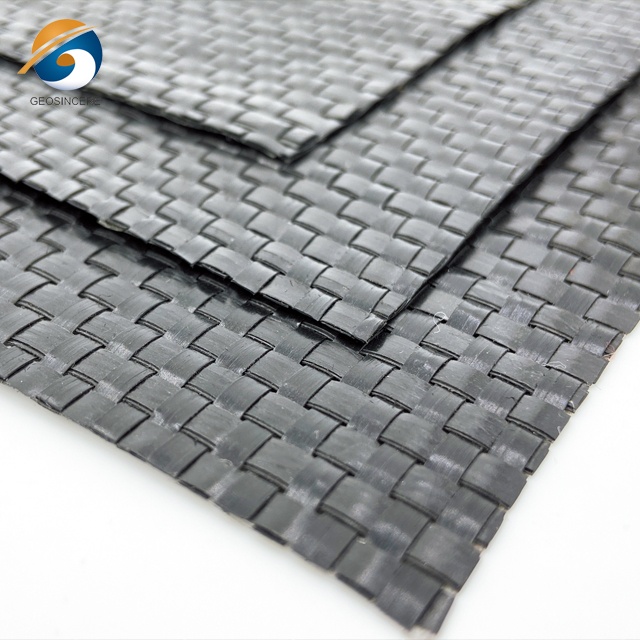

PP woven polypropylene geotextile separation fabric is produced using a structured weaving process built around high-strength polypropylene tapes. The manufacturing cycle consists of tape extrusion, stretching, weaving and heat stabilization.

Tape Extrusion and Stretching

Polypropylene granules are melted and extruded into thin sheets, which are then slit into tapes. These tapes undergo controlled stretching to increase tensile strength and improve dimensional stability.

Woven Fabric Formation

The strengthened tapes are woven using high-speed looms, forming a stable geotextile matrix with uniform pore distribution. The weaving pattern is engineered to resist deformation, ensuring reliable separation between soil layers.

Heat Setting and Quality Control

After weaving, the fabric undergoes heat stabilization to reduce shrinkage and ensure consistent performance. Quality inspections include tensile testing, thickness measurement, pore-size analysis and visual surface evaluation.

Applications Across Key Sectors

The primary function of PP woven polypropylene geotextile separation fabric is to prevent intermixing of soil and aggregate layers while maintaining structural integrity. It is widely used in:

• Road base and subgrade separation

• Railway ballast stabilization

• Ground reinforcement for industrial platforms

• Retaining structure support

• Coastal and riverbank protection layers

• Landfill and drainage system construction

In these scenarios, the fabric improves load distribution, reduces maintenance costs and extends infrastructure lifespan, making it a preferred choice for engineering contractors and government procurement agencies.

Global Buyer Preferences and Procurement Pain Points

International buyers typically prioritize performance reliability, certification consistency and long-term cost value. They expect PP woven polypropylene geotextile separation fabric to comply with standards such as ASTM, ISO and EN requirements. Buyers also focus on tensile strength accuracy, uniform roll dimensions, and stable supply capacity, especially for large-scale infrastructure tenders.

Common pain points include inconsistency in mechanical properties, insufficient documentation, slow production cycles and variability in packaging quality. Buyers increasingly request third-party testing, digital traceability and customized specifications tailored to specific soil conditions.

Conclusion: Reliable Material for Long-Term Ground Stability

As global infrastructure development accelerates, PP woven polypropylene geotextile separation fabric continues to play a vital role in enhancing soil separation, reinforcing roadbeds and improving structural reliability. Its proven mechanical performance, cost efficiency and versatility make it an essential material for engineering contractors, project owners and government agencies worldwide.

We provide technical guidance, detailed specification sheets and customized production options to support international procurement needs. Professionals seeking high-performance woven geotextile solutions are encouraged to request samples, technical documents or tailored quotations.

FAQs

1. What is the standard roll width for woven polypropylene geotextile?

Common widths range from 2 m to 5.8 m, depending on project requirements and transportation limitations.

2. Can this fabric be used in wet, soft soil environments?

Yes. Its high tensile strength and controlled permeability make it suitable for weak subgrade stabilization.

3. What is the typical lifespan of PP woven geotextile in covered applications?

When properly buried under soil or aggregates, service life can exceed 20–35 years depending on environmental conditions.

4. Do you offer custom tensile strength or pore-size specifications?

Yes. We can manufacture according to custom engineering parameters and provide full technical data upon request.

For professional quotations, sample requests and technical consultations, please contact us to obtain detailed engineering support and customized solutions.