Rigid HDPE LDPE Composite Geomembrane Anti Seepage

As environmental protection standards tighten worldwide, **Rigid HDPE LDPE Composite Geomembrane Anti Seepage** systems are becoming indispensable in modern civil and environmental engineering. These materials are extensively used in water reservoirs, landfills, mining projects, and wastewater treatment facilities. The composite geomembrane provides reliable seepage control and long-term chemical resistance, making it a preferred choice for international buyers seeking efficient and sustainable solutions.

According to industry data, the global geomembrane market size exceeded USD 2.5 billion in 2024 and is projected to grow at a CAGR of 6–8% through 2030. The increasing focus on water conservation, soil protection, and waste containment drives this demand. Particularly in regions like Asia-Pacific, the Middle East, and North America, large-scale infrastructure projects and environmental restoration initiatives continue to boost the adoption of high-performance HDPE and LDPE composite geomembranes.

Global Demand for Rigid HDPE LDPE Composite Geomembrane Anti Seepage Materials

As environmental protection standards tighten worldwide, **Rigid HDPE LDPE Composite Geomembrane Anti Seepage** systems are becoming indispensable in modern civil and environmental engineering. These materials are extensively used in water reservoirs, landfills, mining projects, and wastewater treatment facilities. The composite geomembrane provides reliable seepage control and long-term chemical resistance, making it a preferred choice for international buyers seeking efficient and sustainable solutions.

According to industry data, the global geomembrane market size exceeded USD 2.5 billion in 2024 and is projected to grow at a CAGR of 6–8% through 2030. The increasing focus on water conservation, soil protection, and waste containment drives this demand. Particularly in regions like Asia-Pacific, the Middle East, and North America, large-scale infrastructure projects and environmental restoration initiatives continue to boost the adoption of high-performance HDPE and LDPE composite geomembranes.

Technical Composition and Structural Features

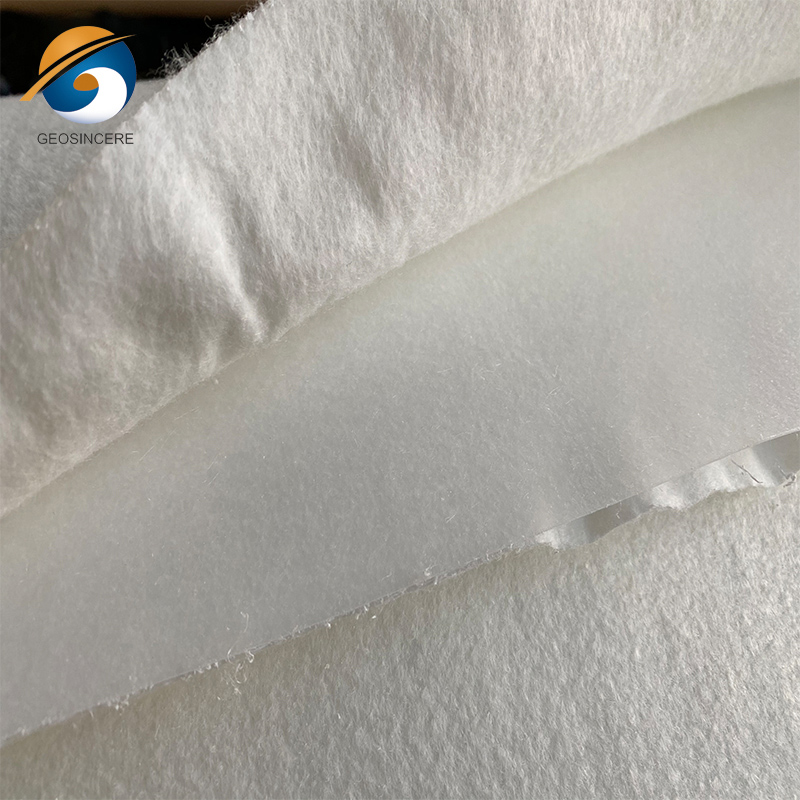

The **Rigid HDPE LDPE Composite Geomembrane** is a multi-layered material engineered for maximum impermeability and tensile strength. It typically consists of high-density polyethylene (HDPE) and low-density polyethylene (LDPE) layers bonded through heat or extrusion processes. This hybrid configuration enhances flexibility, tear resistance, and puncture performance while maintaining a superior anti-seepage barrier.

Technical parameters often include:

– Thickness range: 0.5 mm to 3.0 mm

– Tensile strength: 16–25 MPa depending on density

– Elongation at break: ≥700% (LDPE component improves flexibility)

– Hydraulic conductivity: < 1×10⁻¹³ cm/s

– Operating temperature range: -70°C to +70°C

This combination of rigidity and adaptability allows the composite geomembrane to withstand mechanical stress, temperature fluctuations, and chemical exposure, making it suitable for challenging site conditions such as acidic soils and industrial wastewater environments.

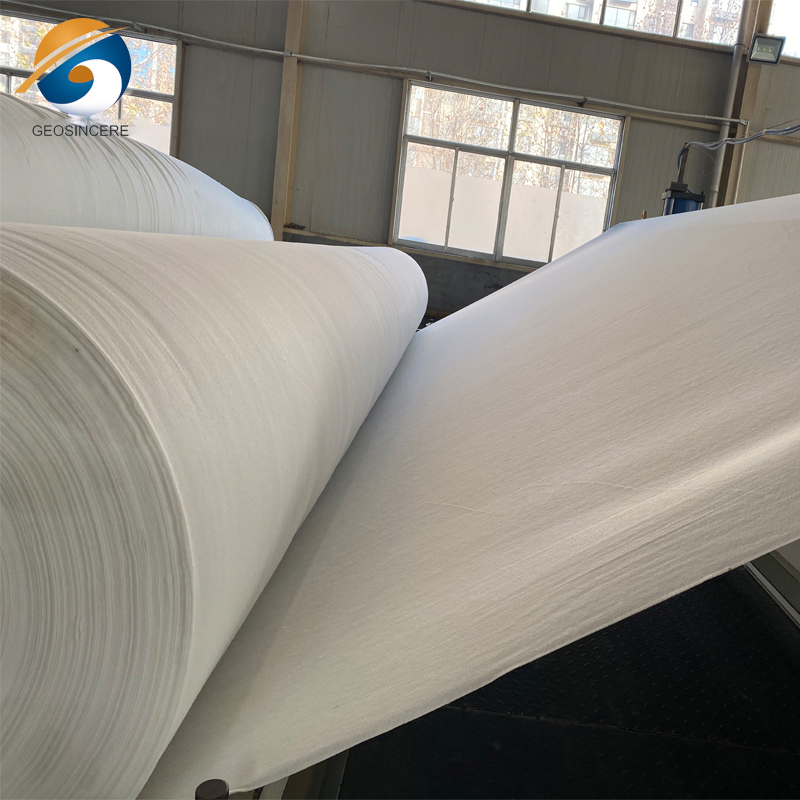

Manufacturing Process and Quality Control

The production of **HDPE LDPE Composite Geomembrane** involves advanced co-extrusion and lamination technologies. The process ensures uniform bonding between the HDPE base layer and the LDPE surface film. The LDPE layer adds softness and flexibility, which improves installation efficiency and reduces the risk of stress cracking during on-site deployment.

Throughout the manufacturing process, each batch undergoes rigorous testing, including:

– Puncture and tear resistance tests

– Hydraulic permeability evaluation

– UV and oxidation resistance testing

– Dimensional stability and thermal aging analysis

Quality control is essential to guarantee consistent performance under different environmental conditions. The final product meets international standards such as ASTM D5321, GRI GM13, and ISO 9001, ensuring that each roll of composite geomembrane is ready for high-demand applications worldwide.

Application Scenarios Across Industries

The **Rigid HDPE LDPE Composite Geomembrane Anti Seepage** solution is widely used across multiple engineering sectors. Its superior impermeability and mechanical performance make it suitable for both public infrastructure and private industrial projects.

Common application fields include:

– **Landfill lining and capping systems:** Preventing leachate leakage and groundwater contamination

– **Agricultural irrigation reservoirs:** Conserving water and reducing seepage losses

– **Mining tailing ponds:** Containing hazardous slurry and minimizing environmental impact

– **Industrial wastewater treatment:** Serving as lining material for evaporation ponds and treatment basins

– **Road and tunnel waterproofing:** Providing structural protection against groundwater intrusion

These applications demonstrate the geomembrane’s adaptability across complex geotechnical environments, supporting both short-term containment and long-term ecological preservation.

Market Trends and International Buyer Insights

Recent market trends highlight growing interest in sustainable materials with enhanced life cycles. Buyers are increasingly seeking geomembranes with recycled polymer content or those produced under certified low-carbon manufacturing systems. Moreover, flexible order customization—such as varied roll widths, thicknesses, and anti-UV treatments—has become a crucial factor influencing international procurement decisions.

Global distributors and engineering contractors prioritize suppliers capable of providing comprehensive technical documentation, including material safety data sheets (MSDS), third-party test reports, and installation guidelines. Another key buying consideration is after-sales technical support, as large-scale projects often require on-site supervision and post-installation quality verification.

Advantages of Rigid HDPE LDPE Composite Geomembrane

The composite design delivers multiple engineering advantages over single-layer geomembranes:

– Superior anti-seepage capability for long-term environmental protection

– High adaptability to uneven terrains due to LDPE flexibility

– Resistance to UV, chemical agents, and microbial degradation

– Excellent cost-effectiveness in large-scale infrastructure projects

With proper installation and maintenance, these geomembranes can maintain integrity for over 50 years, providing sustainable containment solutions in diverse applications worldwide.

FAQs About Rigid HDPE LDPE Composite Geomembrane Anti Seepage

1. What is the difference between HDPE and LDPE in a composite geomembrane?

HDPE provides rigidity, tensile strength, and impermeability, while LDPE adds flexibility and ease of installation. The combination ensures balanced mechanical and hydraulic performance.

2. Can the geomembrane resist chemical and UV degradation?

Yes. The material is treated with stabilizers and antioxidants that enhance UV resistance and prevent chemical corrosion in harsh industrial or natural environments.

3. What is the expected service life of HDPE LDPE composite geomembrane?

When properly installed, the material can last over five decades, maintaining excellent anti-seepage performance and structural stability.

4. Is customization available for project-specific dimensions?

Yes, international buyers can request custom roll widths, thicknesses, and anti-UV coatings to match local environmental and installation requirements.

Professional Call to Action

If your project requires a high-performance **Rigid HDPE LDPE Composite Geomembrane Anti Seepage** solution, we provide technical-grade materials engineered for long-term environmental safety and operational reliability.

Contact our export team today to request detailed product datasheets, free samples, or a customized quotation tailored to your specific project specifications.

Our technical experts are available to provide installation guidance and ensure compliance with international engineering standards.