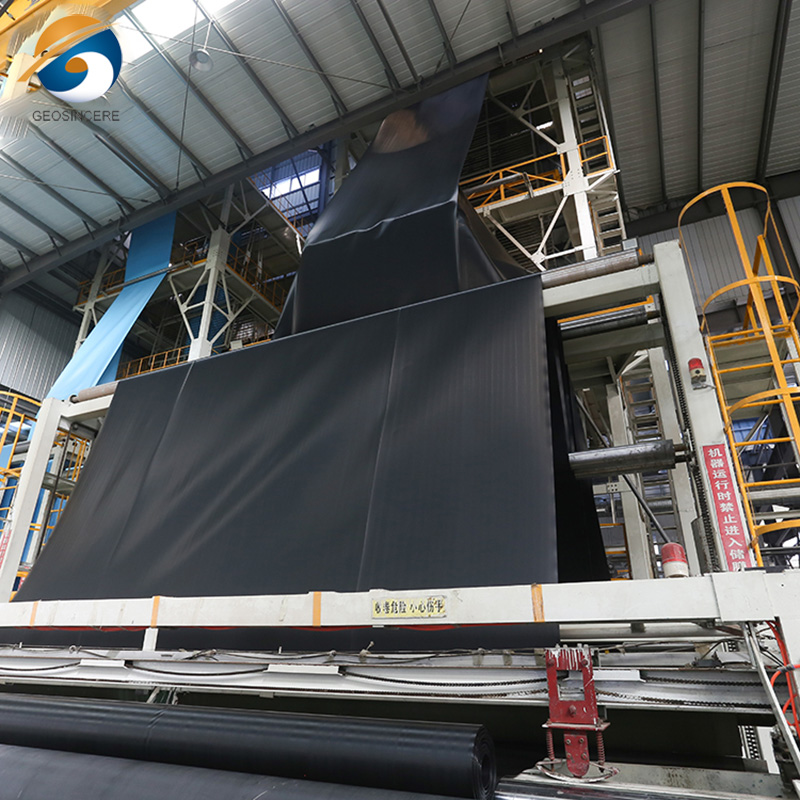

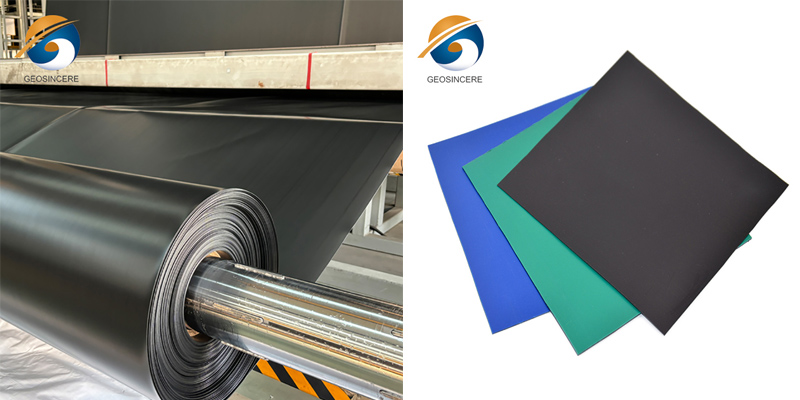

HDPE Pond Liner Geomembrane Circular Tanks for Aquaculture

HDPE pond liner geomembranes are commonly used in the construction of circular tanks for aquaculture. These tanks are designed to hold water and create a suitable environment for fish or other aquatic organisms to grow and thrive.HDPE pond liner geomembranes are preferred for aquaculture applications due to their excellent properties.

HDPE geomembranes are highly impermeable, meaning they provide an effective barrier against water seepage. This is crucial for preventing the loss of water and maintaining the desired water level in the tanks.HDPE is a robust and long-lasting material that can withstand harsh weather conditions, UV radiation, and chemical exposure. It resists punctures, tears, and degradation, ensuring the longevity of the pond liner.HDPE pond liner geomembranes are a reliable choice for constructing circular tanks in aquaculture due to their impermeability, durability, flexibility, and chemical resistance.

High-Density Polyethylene (HDPE) pond liner geomembranes have become a preferred solution for constructing circular tanks in aquaculture due to their durability, chemical resistance, and impermeability. This article provides an in-depth analysis of HDPE pond liner geomembranes used in circular tanks for aquaculture, addressing material properties, engineering principles, installation guidelines, regulatory compliance, and best practices. It aims to guide professionals and aquaculture practitioners in optimizing tank performance while adhering to industry standards.

1. Overview of HDPE Geomembrane for Aquaculture Tanks

Definition:

HDPE geomembranes are synthetic liners made from high-density polyethylene polymers, offering excellent waterproofing and chemical inertness. They serve as flexible, robust barriers in circular tanks, preventing seepage and contamination.

Advantages for Aquaculture:

High tensile strength and puncture resistance

UV resistance for prolonged outdoor exposure

Chemical resistance to fertilizers, disinfectants, and organic waste

Flexibility for easy installation in various tank shapes and sizes

Long service life (20+ years under proper conditions)

2. Engineering Principles and Material Specifications

2.1 Material Properties

Thickness: Commonly ranges from 0.5 mm to 2.0 mm depending on tank size and site conditions.

Tensile Strength: Typically ≥ 20 MPa per ASTM D6693.

Elongation at Break: 700–900%, allowing flexibility during installation and use.

Density: Approximately 0.94 g/cm³, ensuring buoyancy and ease of handling.

UV Stabilizers: Incorporated to meet ASTM G154 standards for UV resistance.

2.2 Design Considerations

Tank Shape: Circular tanks minimize stress concentration and facilitate uniform hydrostatic pressure distribution on the liner.

Subgrade Preparation: Smooth, debris-free foundation with a sand or geotextile cushion layer to prevent liner puncture.

Seam Welding: Thermal extrusion or fusion welding techniques ensure impermeable seams per ASTM D4437.

Anchoring: Secure edges with soil berms or concrete collars to maintain liner position.

3. Regulatory Standards and Compliance

ASTM Standards:

D5199 – Specification for HDPE geomembranes

D7460 – Standard practice for detecting leaks in seams

D4437 – Field testing of seams

EPA Guidelines: Recommendations for aquaculture pond liners regarding water quality and environmental protection.

Local Building Codes: Compliance with civil engineering and aquaculture-specific regulations for tank construction and liner installation is mandatory.

4. Installation Best Practices

Site Inspection: Confirm absence of sharp objects, stones, and debris.

Environmental Conditions: Install in temperatures between 10°C and 40°C to optimize welding and liner flexibility.

Seam Quality Control: Perform destructive and non-destructive testing on seams.

Liner Protection: Use geotextile underlayers and sand blankets to avoid mechanical damage.

Water Filling: Fill gradually to reduce hydraulic stress and ensure liner conforms to tank shape.

5. Operational Considerations and Maintenance

Regular Inspections: Monitor for punctures, UV degradation, and seam integrity annually.

Cleaning: Use soft brushes and mild detergents to avoid damaging the liner surface.

Repairs: Utilize compatible HDPE patches and fusion welding methods for any breaches.

Water Quality: Maintain parameters to avoid chemical degradation of the liner.

Frequently Asked Questions (FAQ)

Q1: What thickness of HDPE geomembrane is recommended for circular aquaculture tanks?

A: Thickness between 1.0 mm to 1.5 mm is commonly recommended balancing durability and cost.

Q2: How long does an HDPE pond liner typically last in aquaculture applications?

A: With proper installation and maintenance, the service life can exceed 20 years.

Q3: Can HDPE liners be recycled after their service life?

A: Yes, HDPE geomembranes are recyclable, supporting sustainable aquaculture practices.

Q4: Is professional installation necessary for these liners?

A: Professional installation is strongly advised to ensure seam integrity and compliance with standards.

Conclusion and Professional Call to Action

HDPE pond liner geomembranes in circular tanks provide an effective, durable solution for aquaculture needs, combining superior material properties with proven engineering design principles. Adhering to regulatory standards and installation best practices maximizes tank efficiency and environmental safety.

We offer specialized consultation and turnkey installation services for HDPE pond liner systems tailored to your aquaculture project requirements. Contact us today to ensure optimal design, installation, and long-term performance of your aquaculture tanks.

Aquaculture HDPE pond liner geomembrane circular tanks offer several advantages. They provide a controlled environment for aquaculture operations, allowing for efficient water management and optimal conditions for aquatic organisms' growth. The impermeability of HDPE liners prevents water loss, reduces the risk of contamination, and helps maintain water quality. The circular shape minimizes stress concentration and facilitates efficient water circulation within the tank.

Aquaculture HDPE pond liner geomembrane circular tanks provide a reliable and effective solution for aquaculture operations. They offer flexibility in design, ease of installation, and long-term durability, contributing to the success and sustainability of aquaculture ventures.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Pond Liner Geomembrane Circular Tanks for Aquaculture Features