2mm Landfill Liner HDPE Geomembrana Para Estanques

The 2mm HDPE Geomembrana Para Estanques is a landfill liner specifically designed for pond applications. It is a synthetic liner that provides an impermeable barrier to prevent the leakage of liquids and gases, protecting the surrounding environment from potential contaminants.Offers excellent resistance to liquid and gas permeation, effectively preventing seepage and leakage. It acts as a reliable barrier to ensure the integrity of the pond liner system.

This HDPE Geomembrana is engineered to withstand harsh conditions, including temperature variations, chemical exposure, and mechanical stresses. Its durability ensures long-term performance and protection for the pond liner.

High-density polyethylene (HDPE) geomembranes, particularly in 2mm thickness, are a standard choice for landfill liners, waste containment, and aquatic applications like estanques (ponds). These geomembranas offer exceptional chemical resistance, impermeability, mechanical strength, and longevity under diverse environmental conditions.

This article provides a technical guide on the use of 2mm HDPE geomembrana for landfill lining and pond waterproofing—covering specifications, engineering roles, compliance requirements, and installation guidelines.

📘 Table of Contents

Introduction to HDPE Geomembranes

Why Choose 2mm Thickness?

Engineering Applications

Technical Specifications

Installation Procedures

Compliance with Global Standards

Case Study Examples

Frequently Asked Questions (FAQ)

Actionable Steps for Procurement

Final Thoughts & Call to Action

1. Introduction to HDPE Geomembranes

A geomembrana HDPE is a synthetic barrier liner made from high-density polyethylene resin. It is used to contain, isolate, or protect water, leachate, gas, or other fluids from migrating into surrounding environments. In Spanish-speaking contexts, these membranes are commonly referred to as geomembranas para estanques o rellenos sanitarios.

Core Properties:

Impermeability: Water permeability rate < 1×10⁻¹³ cm/s

Chemical Resistance: Withstands acids, hydrocarbons, and leachate

UV Stability: Carbon black added for long-term outdoor exposure

Thermal Range: Functional from −40°C to +60°C

2. Why Choose 2mm Thickness?

The 2mm thickness is ideal for heavy-duty containment systems and exposed applications. It offers a high tensile strength and puncture resistance needed in critical engineering structures like:

Class I landfills

Industrial wastewater ponds

Fish and shrimp farming ponds (estanques)

Mining tailing storage

🛡 2mm HDPE is widely recommended where mechanical stress, liner longevity, or fluid aggressiveness are significant design considerations.

3. Engineering Applications

🔹 Landfill Liner Systems

In sanitary landfills, a 2mm HDPE geomembrane acts as the primary barrier layer, placed over compacted clay or a geosynthetic clay liner (GCL) to prevent leachate migration.

🔹 Estanques / Ponds

Used for irrigation reservoirs, fish/shrimp ponds, or rainwater harvesting tanks:

Prevents seepage into subsoil

Maintains water quality

Resists microbial growth and UV exposure

🔹 Mining and Industrial Lagoons

2mm liners are used under heap leach pads, evaporation ponds, and chemical waste storage basins.

4. Technical Specifications

| Property | Typical Value | Standard Test Method |

|---|---|---|

| Thickness (nominal) | 2.0 mm | ASTM D5199 |

| Density | ≥ 0.94 g/cm³ | ASTM D1505 |

| Tensile Strength (Yield) | ≥ 26 kN/m | ASTM D6693 |

| Elongation at Break | ≥ 700% | ASTM D638 |

| Puncture Resistance | ≥ 650 N | ASTM D4833 |

| Carbon Black Content | 2–3% | ASTM D4218 |

| Hydrostatic Resistance | > 2.0 MPa | ASTM D5387 |

| Service Life | 50–75 years (buried) | ISO/TR 20342 |

5. Installation Procedures

Proper installation is critical to ensure impermeability and system performance. Only certified technicians and approved equipment should be used.

Key Installation Steps:

Site Preparation: Grade and compact the subgrade (≤10% slope)

Panel Deployment: Unroll HDPE geomembrane using mechanical spreaders

Seaming: Use hot wedge or extrusion welding (dual-track weld preferred)

Testing: Conduct air channel pressure test and vacuum box test on seams

Anchoring: Use anchor trenches or concrete ballasts to secure edges

Protection Layer: Add geotextile or soil cover if required

⚠ Avoid stretching or folding the membrane during installation.

6. Compliance with Global Standards

🏗 International Norms & Regulations

| Standard | Application |

|---|---|

| ASTM D5885 | Seam strength test |

| GRI-GM13 | Specification for HDPE geomembranes |

| ISO 10319 / ISO 9863-1 | Geosynthetics mechanical properties |

| CQA/QC (EPA/Europe) | Construction quality assurance/control |

7. Case Study: Industrial Pond in Chile

Project: 18,000 m² shrimp farming pond

Location: Valparaíso, Chile

Material: 2mm smooth HDPE

Outcome:

No leakage observed in 6+ years

Temperature resistance up to 48°C

Zero UV degradation (based on surface oxidation test)

8. Frequently Asked Questions (FAQ)

Q1: Can 2mm HDPE be used without a protective layer?

Yes, but only in conditions with no sharp rocks or heavy mechanical load. Otherwise, add a geotextile cushion layer (≥200 g/m²).

Q2: How long will the liner last?

If buried, the life expectancy exceeds 50 years; if exposed, UV-protected geomembranes can last up to 20–25 years.

Q3: Is textured HDPE necessary for pond applications?

Not always. Textured liners are mostly used on slopes >1:3 or where interface friction is needed.

Q4: Is it food-safe for aquaculture ponds?

Yes, most HDPE geomembranes used for estanques are non-toxic, BPA-free, and inert under typical farming conditions.

9. Actionable Steps for Procurement

Before purchasing a 2mm HDPE geomembrana, ensure:

✅ ISO and GRI-GM13 certification

✅ QC documents for resin, thickness, and seam testing

✅ Customized roll width/length for your site layout

✅ On-site or remote technical support

✅ Optional anti-oxidant or UV-resistant additives

📝 This site provides engineering consultation and certified liners tailored to landfill or pond design requirements.

10. Final Thoughts & Call to Action

The 2mm HDPE geomembrana is a proven, engineering-grade material for landfill lining, aquatic pond waterproofing, and industrial waste containment. Backed by decades of field testing, laboratory validation, and compliance with international standards, it offers a cost-effective, durable, and environmentally safe containment solution.

🔍 Looking for technical support, specification sheets, or bulk pricing for 2mm HDPE geomembranes?

📩 Contact this site today to receive a detailed quote, installation guide, and compliance certificates—ensuring your project meets the highest environmental and structural standards.

Key Features

High-density polyethylene (HDPE) material for superior durability and flexibility.

Thickness of 2mm provides reliable containment and protection.

Excellent resistance to chemicals, punctures, and UV radiation.

Prevents the seepage of liquids and gases, safeguarding the environment.

Suitable for landfill ponds and various containment applications.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Product Specifications

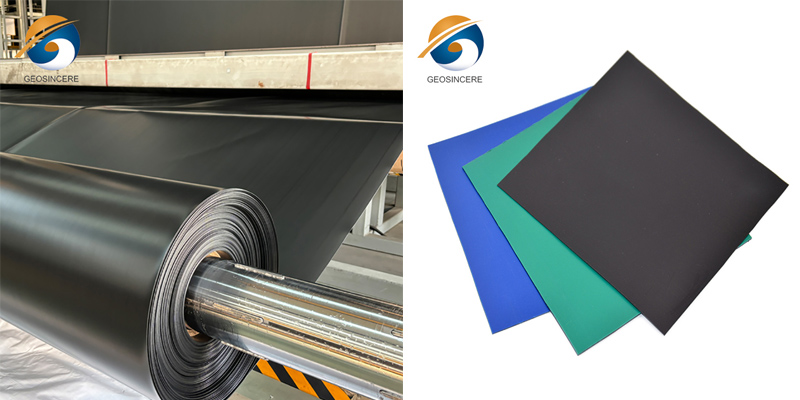

- Material: High Density Polyethylene (HDPE)

- Thickness: Varies based on project requirements (e.g., 0.1mm - 3.0mm)

- Roll Width: Customizable (commonly 1m - 10m)

- Roll Length: Customizable (commonly 50m - 200m)

- Color: Black, Blue, Green (other colors available upon request)

2mm Landfill Liner HDPE Geomembrana Para Estanques Features

Excellent Chemical Resistance.

Outstanding Stress Crack Capacity.

Lowest Permeability.

Excellent UV Resistance.

Stable Low Temperature Embrittlement Resistance.

Proven Performance.

Fast Deployment.

Easy Transportation.

ISO9001 Certificated Geomembrana Factory.

Meet or Exceed All Aspects of GRI GM13.

Complete Width and Thickness Specifications.

Competitive Factory Price.

ODM/OEM are Available.

Applications of 2mm Landfill Liner HDPE Geomembrana Para Estanques