Commercial Large Pond Liner Impermeable HDPE Geomembrane

Manufacturing Process

Engineering Production Steps

Selection of virgin HDPE resin with certified melt flow index

Precise dosing of carbon black and antioxidant additives

High-temperature extrusion using flat-die or blown-film lines

Calendering to achieve uniform thickness control

Online inspection for pinholes, gels, and thickness deviation

Controlled cooling and roll winding

Batch sampling for mechanical and aging tests

Critical Process Controls

Stable extrusion temperature to prevent polymer degradation

Uniform resin dispersion to avoid weak points

Continuous quality monitoring in accordance with ASTM and ISO standards

What Is Commercial Large Pond Liner Impermeable HDPE Geomembrane

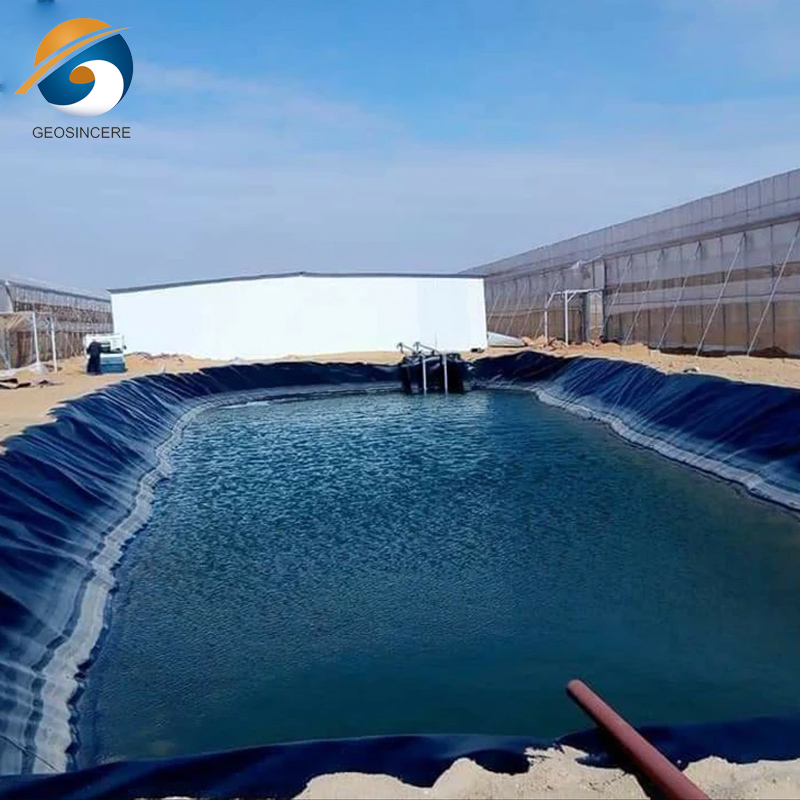

Commercial Large Pond Liner Impermeable HDPE Geomembrane is a high-density polyethylene synthetic liner engineered for large-scale water containment projects. It provides long-term impermeability, chemical resistance, and structural stability for commercial ponds, reservoirs, aquaculture farms, and industrial water management systems.

Technical Parameters and Specifications

The following specifications are widely adopted in commercial and EPC pond liner projects and align with international geomembrane engineering practices.

Material: High-Density Polyethylene (HDPE)

Thickness Range: 0.5 mm – 3.0 mm

Density: ≥ 0.94 g/cm³

Tensile Strength at Yield: ≥ 15 MPa

Elongation at Break: ≥ 700%

Puncture Resistance: ≥ 640 N

Carbon Black Content: 2.0–3.0%

UV Resistance: ≥ 50% retained after 1600 hours

Service Temperature: -40°C to +80°C

Design Service Life: 20–30 years under covered conditions

Structure and Material Composition

Commercial HDPE geomembranes are typically produced as homogeneous or co-extruded structures to meet different engineering requirements.

Surface Layer: UV-stabilized HDPE with carbon black for sunlight protection

Core Layer: High-purity polyethylene resin providing mechanical strength

Optional Textured Layer: Improves friction on slopes and embankments

Interface Layer: Designed for compatibility with geotextiles or soil subgrades

Manufacturing Process

Engineering Production Steps

Selection of virgin HDPE resin with certified melt flow index

Precise dosing of carbon black and antioxidant additives

High-temperature extrusion using flat-die or blown-film lines

Calendering to achieve uniform thickness control

Online inspection for pinholes, gels, and thickness deviation

Controlled cooling and roll winding

Batch sampling for mechanical and aging tests

Critical Process Controls

Stable extrusion temperature to prevent polymer degradation

Uniform resin dispersion to avoid weak points

Continuous quality monitoring in accordance with ASTM and ISO standards

Industry Comparison

| Material | HDPE Geomembrane | LLDPE Geomembrane | PP Geomembrane | EPDM Rubber |

|---|---|---|---|---|

| Impermeability | Excellent | Excellent | Excellent | Good |

| Mechanical Strength | Very High | High | Medium | Medium |

| UV Resistance | Very High | High | High | Medium |

| Installation Cost | Medium | Medium | Medium | High |

| Large Pond Suitability | Excellent | Good | Good | Limited |

Application Scenarios

Large-scale aquaculture ponds and shrimp farms

Industrial water storage and wastewater lagoons

Commercial irrigation reservoirs

Mining and tailings containment ponds

Municipal and EPC water infrastructure projects

Core Pain Points and Engineering Solutions

Seepage Loss: Use thicker HDPE liners with certified welding quality

Subgrade Damage: Install protective geotextile underlay

UV Aging: Specify carbon black–stabilized HDPE formulations

Slope Instability: Apply textured geomembranes on embankments

Risk Warnings and Mitigation Strategies

Avoid sharp stones or debris during subgrade preparation

Ensure qualified hot-wedge or extrusion welding teams

Allow for thermal expansion during installation

Conduct non-destructive seam testing after welding

Procurement and Selection Guide

Define pond dimensions, depth, and hydraulic pressure

Select liner thickness based on load and service life

Determine smooth or textured surface requirements

Verify compliance with international geomembrane standards

Review laboratory test reports and quality certifications

Assess supplier manufacturing capacity and project experience

Confirm availability of installation guidance and after-sales support

Engineering Case Example

In a Middle East commercial aquaculture project, a 2.0 mm HDPE geomembrane was installed across a 60,000 m² large pond system. The liner was welded using automated hot-wedge machines and protected with geotextile layers, achieving zero leakage and stable operation under high-temperature conditions for over three years.

Frequently Asked Questions

Is HDPE suitable for large ponds? Yes, HDPE offers high strength and durability.

What thickness is recommended? 1.0–2.5 mm for most commercial ponds.

Can HDPE liners be exposed? Yes, with proper UV stabilization.

How are seams joined? By hot-wedge or extrusion welding.

What is the expected lifespan? Up to 30 years under proper conditions.

Is geotextile mandatory? Strongly recommended for protection.

Can HDPE resist chemicals? Excellent resistance to most acids and salts.

Are textured liners necessary? Recommended for slopes above 3:1.

What temperatures can HDPE handle? -40°C to +80°C.

Can liners be repaired? Yes, by localized welding patches.

CTA – Commercial Inquiry

For project quotations, technical datasheets, or engineering samples of Commercial Large Pond Liner Impermeable HDPE Geomembrane, please submit your project specifications to receive professional technical and commercial support.

E-E-A-T Author Credentials

This content is developed by an engineering team with over 15 years of experience in geomembrane materials and large-scale water containment systems, supporting EPC contractors, infrastructure developers, and international procurement managers across industrial and commercial projects.

Company Profile