Geomembrana in HDPE

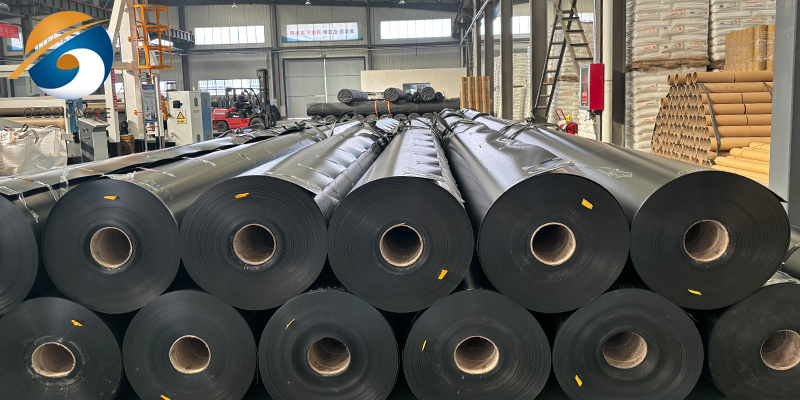

Manufacturing Process

The performance consistency of geomembrana in HDPE is directly related to its controlled manufacturing process.

Raw material batching and mixing of HDPE resin and additives

Extrusion through flat die or blown film system

Sheet calendering and thickness control

Surface texturing (if required)

Cooling, trimming, and winding

Inline thickness, density, and surface inspection

Finished roll packaging and batch identification

Product Definition

Geomembrana in HDPE is a high-density polyethylene impermeable liner engineered for containment, separation, and environmental protection in civil, mining, water, and waste management projects, offering long-term chemical resistance, structural stability, and controlled permeability under demanding engineering conditions.

Technical Parameters and Specifications

For professional engineering applications, geomembrana in HDPE must comply with standardized, verifiable technical parameters.

Thickness range: 0.5 mm / 0.75 mm / 1.0 mm / 1.5 mm / 2.0 mm / 2.5 mm

Density: ≥0.94 g/cm³

Tensile strength at yield: ≥15 MPa

Tensile elongation at break: ≥700%

Puncture resistance: ≥500 N (CBR method)

Carbon black content: 2.0–3.0%

Carbon black dispersion: Grade 1–2

Oxidative induction time (OIT): ≥100 min (standard)

Permeability coefficient: ≤1.0 × 10⁻¹³ cm/s

Structure and Material Composition

Geomembrana in HDPE is a homogeneous polymeric sheet designed for impermeability and durability.

Base Polymer: High-density polyethylene resin

Stabilizer System: Carbon black for UV resistance

Antioxidants: Thermal and oxidative aging control

Surface Options:

Smooth surface for general containment

Textured or double-textured surface for slope stability

Manufacturing Process

The performance consistency of geomembrana in HDPE is directly related to its controlled manufacturing process.

Raw material batching and mixing of HDPE resin and additives

Extrusion through flat die or blown film system

Sheet calendering and thickness control

Surface texturing (if required)

Cooling, trimming, and winding

Inline thickness, density, and surface inspection

Finished roll packaging and batch identification

Industry Comparison

| Property | HDPE Geomembrane | LLDPE Geomembrane | EPDM Rubber Liner | PVC Geomembrane |

|---|---|---|---|---|

| Chemical Resistance | Excellent | Good | Moderate | Moderate |

| UV Resistance | Excellent | Good | Good | Moderate |

| Flexibility | Moderate | High | Very High | High |

| Service Life | 30–50 years | 20–30 years | 20–25 years | 15–20 years |

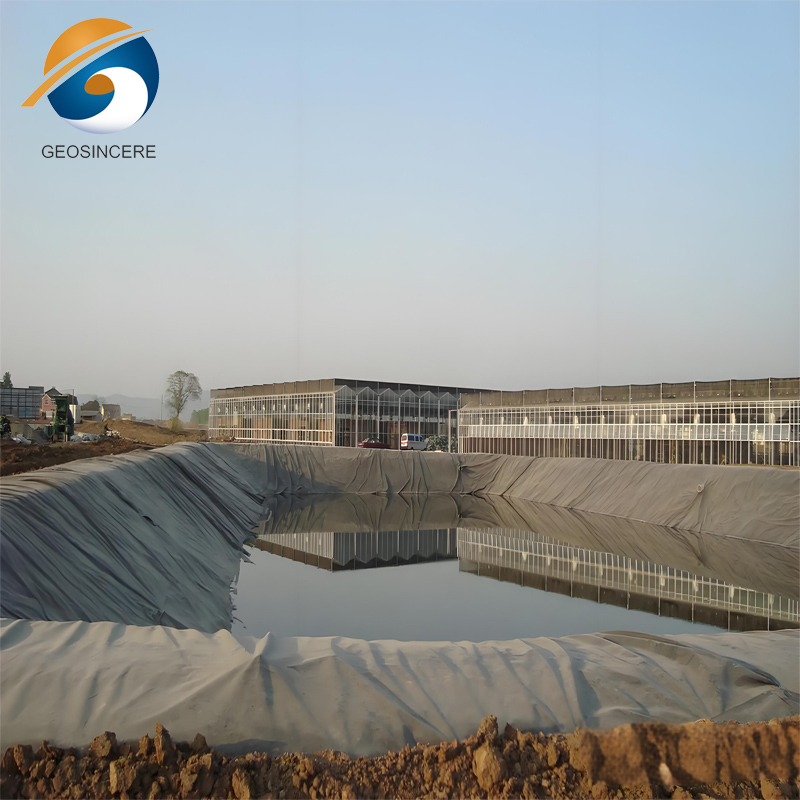

Application Scenarios

Geomembrana in HDPE is widely used across infrastructure and environmental engineering sectors.

Distributors: Standard rolls for water and waste containment markets

EPC contractors: Landfills, tailings dams, and industrial ponds

Engineering consultants: Environmental barrier design

Government projects: Water reservoirs and canal lining systems

Core Pain Points and Engineering Solutions

Leakage risk: Solved by double-liner systems and quality welding

Slope instability: Addressed using textured geomembrana in HDPE

UV degradation: Controlled through carbon black stabilization

Installation damage: Reduced via protective geotextile layers

Risk Warnings and Mitigation

Improper specification or installation of geomembrana in HDPE can compromise system integrity.

Avoid installing over sharp or poorly compacted subgrades

Do not weld under rain, dust, or extreme wind conditions

Ensure qualified technicians perform seam welding

Verify roll traceability and batch test reports

Procurement and Selection Guide

Define containment type and chemical exposure

Select thickness based on load and puncture risk

Determine surface type (smooth or textured)

Verify compliance with ASTM or GRI standards

Review manufacturing capacity and quality control

Request welding guidelines and installation manuals

Conduct pre-installation material testing

Engineering Case Application

In a municipal solid waste landfill project, a 2.0 mm double-textured geomembrana in HDPE was installed over a compacted clay liner and protective geotextile. The system covered 45,000 m² and achieved leak detection performance compliant with environmental regulations after five years of monitored operation.

FAQ

Q1: What thickness is typical for landfills? A: Usually 1.5–2.0 mm.

Q2: Is HDPE geomembrane UV resistant? A: Yes, with proper carbon black content.

Q3: Can it resist chemicals? A: Yes, including acids and alkalis.

Q4: What welding method is used? A: Hot wedge or extrusion welding.

Q5: Is textured HDPE necessary on slopes? A: Recommended for stability.

Q6: What is the service life? A: Up to 50 years in buried conditions.

Q7: Can it be used in potable water? A: Yes, with certified grades.

Q8: How is seam quality tested? A: Air pressure or vacuum box testing.

Q9: Is HDPE recyclable? A: Yes, under controlled conditions.

Q10: What standards apply? A: ASTM D5885, GRI GM13.

Call to Action

For detailed technical datasheets, engineering samples, welding guidelines, or project-based quotations related to geomembrana in HDPE, procurement and engineering teams are invited to request comprehensive technical documentation.

E-E-A-T Author Credentials

This article is prepared by a geosynthetics engineering specialist with over 15 years of experience in environmental containment systems, civil infrastructure projects, and international B2B procurement and specification support.