HDPE Geomembrane 2mm

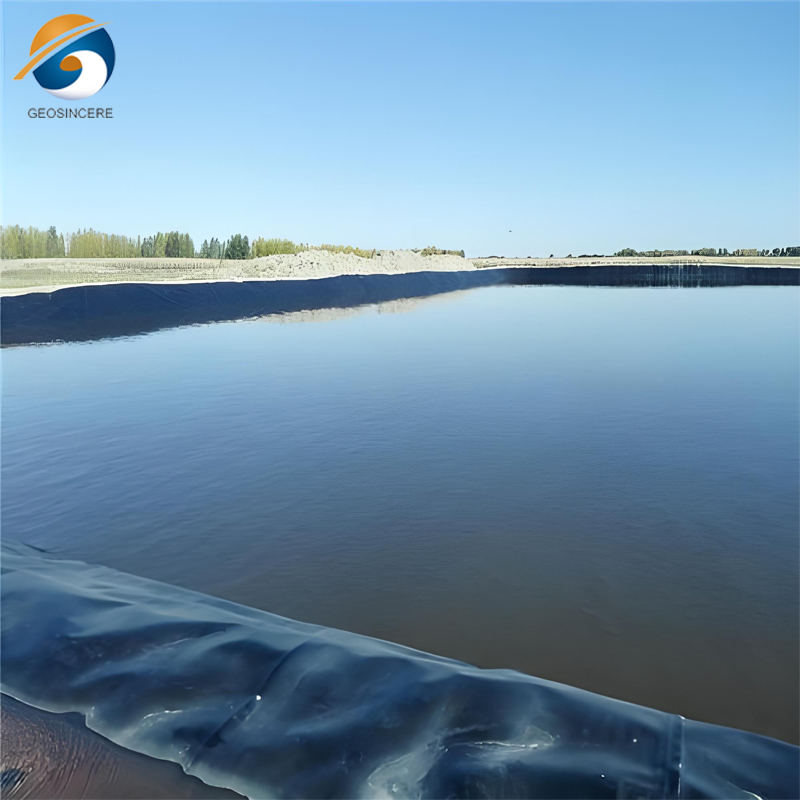

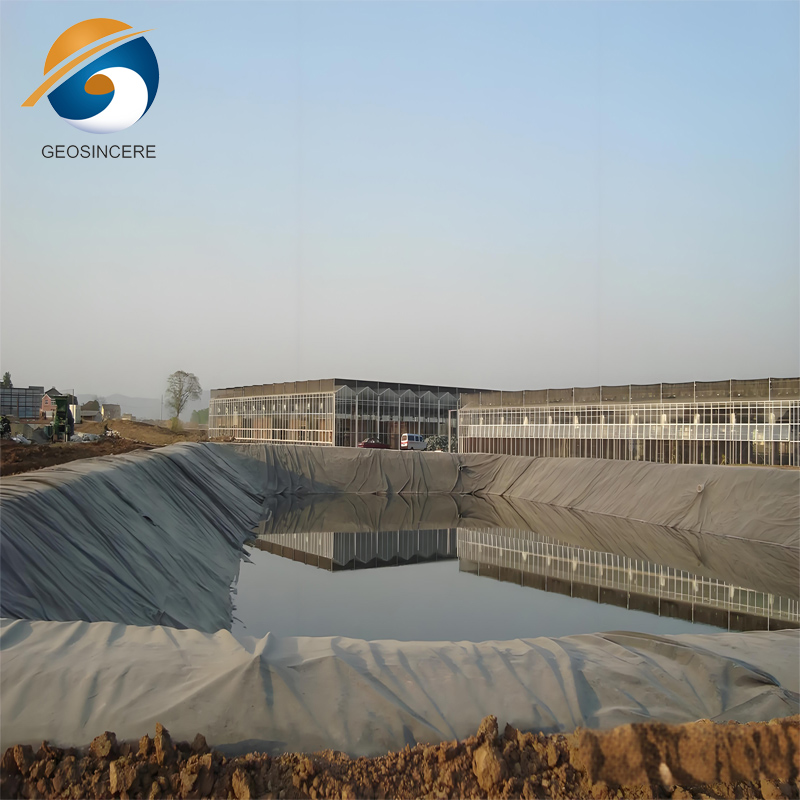

HDPE Geomembrane 2mm, with a thickness of 2mm, is a robust and versatile liner material commonly used in various environmental and engineering applications. This geomembrane is known for its exceptional strength, chemical resistance, and impermeability, making it an ideal choice for projects such as landfills, containment ponds, and wastewater treatment facilities. The 2mm thickness provides an optimal balance of durability and flexibility, allowing it to withstand harsh environmental conditions while maintaining its structural integrity. HDPE geomembranes are engineered to resist UV radiation, punctures, and environmental stress, ensuring long-term performance and reliability. Furthermore, the ease of installation and the ability to weld seams create a seamless barrier, significantly reducing the risk of leaks. With its outstanding performance characteristics, 2mm HDPE geomembrane is a preferred solution for projects requiring effective containment and environmental protection.

The HDPE geomembrane with a thickness of 2mm is a highly durable and effective barrier material widely utilized in various applications, including landfills, waste containment, and environmental protection projects. Its high-density polyethylene composition provides excellent resistance to chemicals, UV radiation, and mechanical stress, making it suitable for both above-ground and below-ground installations. The 2mm thickness strikes a perfect balance between flexibility and strength, allowing it to conform to uneven surfaces while maintaining its integrity under extreme conditions. One of the key advantages of HDPE geomembranes is their impermeability, which prevents the migration of liquids and contaminants, thereby protecting the surrounding environment. Additionally, the geomembrane can be easily welded to create seamless joints, minimizing the risk of leaks and ensuring a reliable barrier. With its long service life and low maintenance requirements, the 2mm HDPE geomembrane is an ideal choice for engineers and environmental professionals seeking a robust solution for effective containment and sustainable project outcomes.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

HDPE Geomembrane 2mm Features

High-Density Polyethylene (HDPE) geomembranes with a thickness of 2mm are widely recognized as robust, durable, and chemically resistant liners for containment and environmental protection applications. This article provides a detailed technical analysis of 2mm HDPE geomembranes, covering material properties, engineering principles, regulatory standards, installation practices, and safety considerations.

What is a 2mm HDPE Geomembrane?

A 2mm HDPE geomembrane is a synthetic liner made from high-density polyethylene resin, with a thickness of 2 millimeters. It is commonly used as an impermeable barrier in industries such as waste containment, mining, water reservoirs, and landfill lining.

Key Material Properties

Density: Typically 0.94–0.97 g/cm³

Tensile Strength: ≥ 20 MPa (ASTM D638)

Elongation at Break: ≥ 700% (ASTM D638)

Puncture Resistance: ≥ 450 N (ASTM D4833)

UV Resistance: Carbon black additive ensures resistance to ultraviolet degradation

Chemical Resistance: Excellent against acids, alkalis, hydrocarbons, and salts

Temperature Range: Operational from -60°C to +80°C

Engineering Applications

Landfill liners and covers

Mining heap leach pads and tailings containment

Water and wastewater treatment ponds

Canal and reservoir liners

Secondary containment for chemical tanks

The 2mm thickness balances mechanical strength and flexibility, making it suitable for medium to large-scale projects with moderate mechanical stresses.

Industry Standards and Compliance

Compliance with global standards ensures reliable performance:

GRI GM13: Physical and mechanical properties specification for HDPE geomembranes

ASTM D5199: Standard test method for thickness measurement

ASTM D5885: Standard specification for HDPE geomembrane materials

ISO 9001: Quality management systems for manufacturing

EPA RCRA Subtitle D: Environmental regulations for landfill liners in the USA

Installation Best Practices

Site Preparation:

Ensure the subgrade is smooth, free of sharp objects, and compacted.

Use a protective layer such as geotextile if necessary.

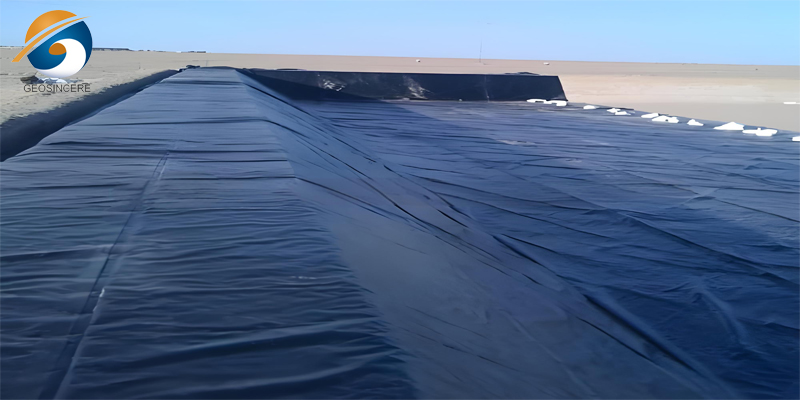

Deployment:

Unroll the geomembrane carefully to avoid stretching or damage.

Allow for thermal expansion by leaving slack during installation.

Seaming:

Utilize extrusion or fusion welding methods.

Perform destructive and non-destructive testing (e.g., air channel tests) on seams.

Anchoring:

Secure edges in anchor trenches to prevent displacement.

Inspection:

Conduct visual inspections and electronic leak detection before covering.

Safety and Handling Considerations

Store rolls horizontally in dry, shaded areas.

Avoid exposure to sharp objects and heavy machinery during installation.

Use personal protective equipment (PPE) when welding or handling the material.

Follow manufacturer guidelines for thermal welding temperatures and speeds.

Frequently Asked Questions (FAQs)

Q1: Why choose 2mm thickness over thinner geomembranes?

A: 2mm provides enhanced puncture resistance, durability, and longer lifespan, making it ideal for applications with higher mechanical demands.

Q2: How resistant is HDPE geomembrane to chemicals?

A: HDPE exhibits excellent chemical resistance to a broad spectrum of substances, including acids, bases, and solvents.

Q3: Can 2mm HDPE geomembranes be repaired if damaged?

A: Yes, damaged areas can be repaired on-site using compatible patching materials and welding techniques.

Q4: What is the expected service life of a 2mm HDPE geomembrane?

A: Under optimal conditions, the service life can exceed 30 years.

Conclusion and Call to Action

The 2mm HDPE geomembrane stands as a versatile, reliable solution for environmental containment and infrastructure projects. Its superior mechanical properties, chemical resistance, and regulatory compliance make it a top choice for engineers and project managers worldwide.

We offer technical consultation, supply chain solutions, and installation support for HDPE geomembranes tailored to your project requirements. Reach out today to ensure your containment systems meet the highest standards of quality and durability.