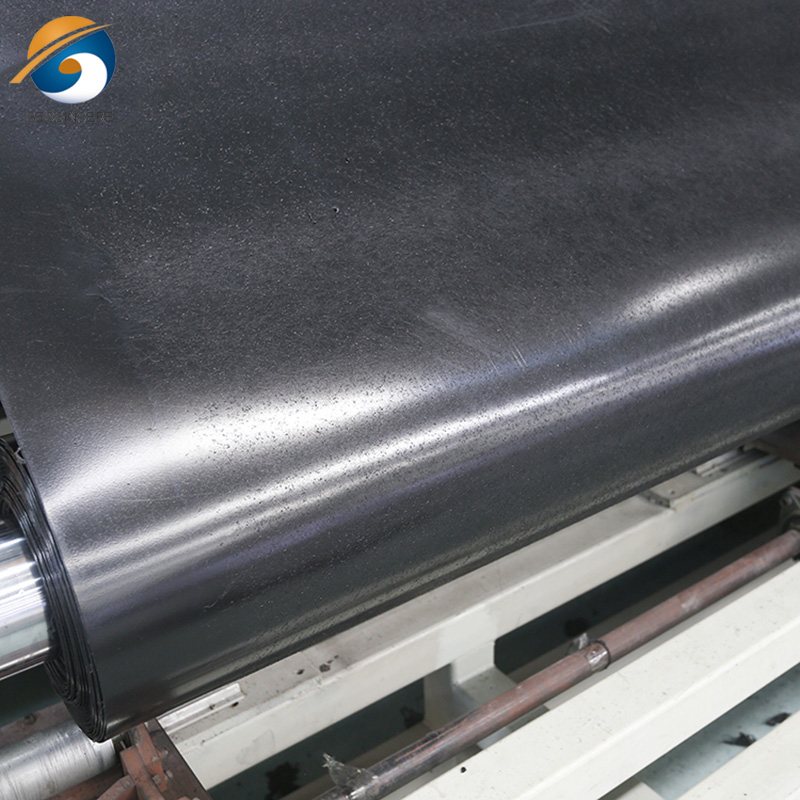

Black Plastic Reinforced Polyethylene Pond Landfill Liner

A black plastic reinforced polyethylene pond landfill liner is a type of liner used in the construction of landfills and containment ponds. It is designed to prevent the leakage of liquids, such as leachate from landfills or water from containment ponds, into the surrounding environment.

The liner is typically made of high-density polyethylene (HDPE), which is a strong and durable plastic material. The black color of the liner helps to prevent the penetration of sunlight, which can degrade the material over time.The purpose of using a black plastic reinforced polyethylene pond landfill liner is to create a barrier that effectively contains and controls the liquids within the landfill or containment pond. This helps to prevent contamination of groundwater, soil erosion, and the release of potentially hazardous substances into the environment. The liner also provides stability to the structure and helps to extend its lifespan.

When it comes to environmental protection, containment efficiency, and water retention, the Black Plastic Reinforced Polyethylene Pond Landfill Liner stands out as the premier choice for engineers, contractors, and environmental agencies. This durable geomembrane provides a long-lasting, cost-effective solution for ponds, landfills, and other liquid or solid containment systems.

With advanced multilayer reinforcement and superior impermeability, the Black Plastic Reinforced Polyethylene Pond Landfill Liner offers exceptional resistance to chemicals, UV rays, and punctures, making it the preferred lining system in both civil and environmental applications.

What is a Black Plastic Reinforced Polyethylene Pond Landfill Liner?

The Black Plastic Reinforced Polyethylene Pond Landfill Liner is a heavy-duty geomembrane composed of high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) with integrated scrim reinforcement. This structure significantly boosts tensile strength and dimensional stability while maintaining the liner’s flexibility and weldability.

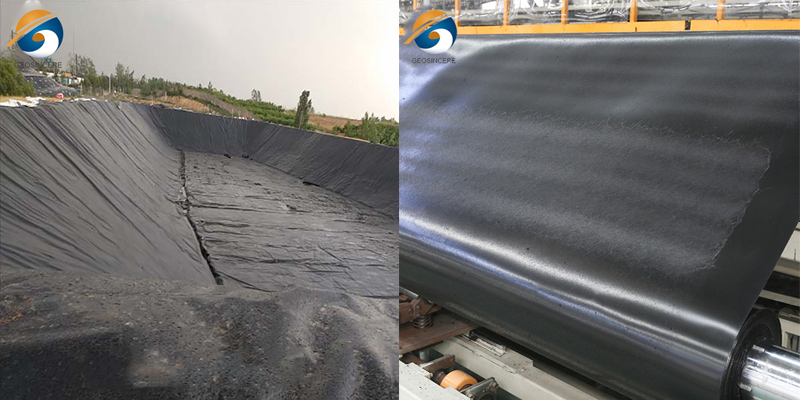

Designed specifically for long-term performance, the Black Plastic Reinforced Polyethylene Pond Landfill Liner serves as a crucial barrier in lining systems for waste containment, water reservoirs, and aquaculture ponds.

Key Advantages of Black Plastic Reinforced Polyethylene Pond Landfill Liner

✅ Reinforced Durability

The added polyethylene reinforcement delivers exceptional tear resistance and long-term structural stability.

✅ Superior Chemical Resistance

Engineered to resist corrosive leachates, wastewater, and hydrocarbons—ideal for landfill and industrial sites.

✅ UV and Thermal Stability

The black plastic material offers excellent UV resistance, allowing for long-term exposure in outdoor applications.

✅ Waterproof and Leak-Proof

High impermeability ensures zero seepage, making it perfect for pond and reservoir lining.

✅ Environmentally Safe

The non-toxic material of the Black Plastic Reinforced Polyethylene Pond Landfill Liner is eco-friendly and safe for aquatic life.

Applications of Black Plastic Reinforced Polyethylene Pond Landfill Liner

The versatility of the Black Plastic Reinforced Polyethylene Pond Landfill Liner makes it ideal for a wide range of applications:

🟢 Landfill Lining & Capping Systems

🟢 Wastewater Treatment Plants

🟢 Agricultural Irrigation Ponds

🟢 Mining Leach Pads

🟢 Aquaculture Farms & Fish Ponds

🟢 Rainwater Harvesting Tanks

🟢 Stormwater Retention Basins

Whether you're building a lined lagoon or managing industrial waste, this liner ensures reliable performance and compliance with environmental regulations.

Technical Specifications

| Specification | Details |

|---|---|

| Product Name | Black Plastic Reinforced Polyethylene Pond Landfill Liner |

| Material | HDPE / LLDPE with Reinforced Scrim |

| Thickness Range | 0.75mm – 2.5mm |

| Width | Up to 8 meters |

| Roll Length | 50m – 200m (custom sizes available) |

| Color | Black (UV-stabilized) |

| Tensile Strength | ≥ 28 MPa |

| Elongation at Break | ≥ 600% |

| Lifespan | 20+ years (with proper installation) |

| Standard Compliance | ASTM, GRI-GM13, ISO 9001 |

Installation Guidelines

Surface Preparation: Ensure the ground is smooth, compacted, and debris-free.

Liner Deployment: Unroll and position the liner with minimal wrinkles or folds.

Seam Welding: Use hot wedge or extrusion welders to join panels securely.

Anchor Trenching: Secure edges in anchor trenches for added protection.

Testing & Inspection: Perform vacuum or air pressure tests on seams to ensure leak-proof integrity.

Why Choose a Black Plastic Reinforced Polyethylene Pond Landfill Liner?

Opting for the Black Plastic Reinforced Polyethylene Pond Landfill Liner means choosing reliability, durability, and environmental security. Its multi-layer structure provides both strength and flexibility, ensuring long-term containment performance. Whether it’s for protecting groundwater from hazardous leachates or retaining millions of gallons of water in an aquaculture system, this liner delivers peace of mind backed by science and engineering.

Conclusion: A Smart Investment for Modern Containment Needs

In the field of geosynthetics, the Black Plastic Reinforced Polyethylene Pond Landfill Liner is more than just a membrane—it's an essential tool for sustainability, safety, and operational efficiency. With proven results across diverse sectors, it is the go-to liner for projects that demand the best in geomembrane performance.

Parameter

Test Properties | Unit | Standard | Test frequency | BM10 | BM15 | BM20 | BM25 |

Thickness | mm | D5994 | per roll | 1.00 | 1.50 | 2.00 | 2.50 |

Asperity Height | mm | D7446 | Every 2nd roll (2) | 0.25 | |||

Density | g/cc | D1505/0792 | 90.000kg | 0.94 | |||

Tensile Properties | |||||||

Yield Strength | Kn/m | D6693 Type Iv | 9.000 kg | 15 | 22 | 29 | 37 |

Break Strength | Kn/m | 10 | 16 | 21 | 26 | ||

Yield Elongation | % | 12 | 12 | 12 | 12 | ||

Break Elongation | % | 100 | 100 | 100 | 100 | ||

Tear Resistance | n | D1004 | 20.000kg | 125 | 187 | 249 | 311 |

Puncture Resistance | n | D4883 | 20,000kg | 267 | 400 | 534 | 667 |

Stress Crack Resistance | hr | D5397(App) | per GRlGM-10 | 300 hr | |||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||

0xidative Induction Time | |||||||

Standard OlT | Min | D3895 | 90.000kg | 100 min | |||

High pressure OlT | D5885 | 90.000kg | 400 min | ||||

Oven Aging at 85°C retained after 90 days | % | D5721 | per each formulation | 55% | |||

Standard 0lT | D3895 | 80% | |||||

High pressure OlT | D5885 | 80% | |||||

UV Resistance | |||||||

High Pressure OlT -% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||

Roll Width | m | 7 | 7 | 7 | 7 | ||

Roll Length | m | 210 | 140 | 105 | 70 | ||

Size stability | % | 2% | |||||

Black Plastic Reinforced Polyethylene Pond Landfill Liner Features

Can be textured on one or both sides for your demands.

Increased Friction ,improving stability and performance.

Outstanding ultraviolet and chemical resistance.

Durability UV radiation, chemicals, and punctures.

High tensile strength and low elongation.

Excellent friction coefficient and tensile strength with Geotextile Reinforcement performance.

Excellent water impermeability, corrosion and aging resistance.

Enhanced Stability ,resist external forces.

Impermeable, antifouling, antiskid function.

Flexibility, Light weight, easy construction and good overall continuity.

Applications of Black Plastic Reinforced Polyethylene Pond Landfill Liner