Landscaping Plastic Geomembrane HDPE Liner

Landscaping Plastic Geomembrane HDPE Liner is a versatile plastic liner widely used in civil engineering and environmental protection applications, primarily for waterproofing and containment. Known for its excellent chemical resistance and UV stability, HDPE geomembrane is suitable for a variety of environmental conditions, including both wet and dry climates. This material is commonly utilized in reservoirs, landfills, wastewater treatment facilities, and agricultural drainage systems, effectively preventing water infiltration and soil contamination. Additionally, HDPE geomembrane boasts outstanding mechanical strength and flexibility, making it easy to install and ensuring long-term stability and reliability. By incorporating HDPE geomembrane into landscaping and civil engineering projects, environmental risks can be significantly reduced, groundwater resources can be protected, and sustainable development can be promoted.

In modern landscaping and civil engineering applications, HDPE geomembrane liners are widely used for water retention, soil stabilization, and environmental protection. Known for their durability, chemical resistance, and impermeability, landscaping plastic HDPE liners are essential in various infrastructure and environmental projects. This article provides a detailed analysis of HDPE liners used in landscaping, covering material specifications, engineering principles, regulatory guidelines, operational safety, and installation considerations.

What Is a Landscaping Plastic Geomembrane HDPE Liner?

A High-Density Polyethylene (HDPE) geomembrane liner is a flexible plastic sheet made from high-density polyethylene resin. It serves as an impermeable barrier for fluid or gas containment. In landscaping, these liners are typically used for ponds, decorative lakes, stormwater retention basins, and landfill capping systems.

Key Properties of HDPE Liners

High chemical resistance: Excellent resistance to acids, alkalis, and hydrocarbons.

UV stability: Stabilized with carbon black to resist ultraviolet degradation.

Tensile strength: Ranges between 25-40 MPa, depending on thickness.

Environmental safety: Complies with standards such as GRI-GM13 and ASTM D5885.

Applications in Landscaping

Artificial ponds and lakes

Irrigation reservoirs

Retaining walls and soil slope stabilization

Green roof waterproofing

Reed bed construction for natural wastewater treatment

Industry Standards and Certifications

Several global standards ensure the quality and performance of HDPE geomembranes:

GRI-GM13: Specifies physical, mechanical, and endurance properties.

ASTM D638 / D6693: Measures tensile strength and elongation.

ISO 9001 / ISO 14001: Assures manufacturing quality and environmental compliance.

CE Marking (for European compliance): Ensures conformity with EU safety, health, and environmental protection requirements.

Factors to Consider When Choosing a Landscaping HDPE Liner

1. Thickness and Material Grade

Standard thicknesses: 0.5 mm, 1.0 mm, 1.5 mm, and 2.0 mm.

Thicker liners (≥1.5 mm) are preferable for long-term containment or when subjected to mechanical stress.

2. Site Conditions

Evaluate soil composition, groundwater level, and subgrade preparation.

HDPE liners should be installed over a well-compacted base layer with no sharp stones or debris.

3. Chemical Compatibility

Use compatibility charts (e.g., EPA SW-846) to assess liner resistance to any chemicals present in soil or water.

4. Welding and Seaming Methods

Use hot wedge welding or extrusion welding for sealing overlaps.

Conduct non-destructive testing (NDT) such as air pressure tests or spark testing post-welding.

5. Regulatory and Environmental Compliance

Must adhere to local environmental agency guidelines for runoff control, leachate prevention, and ecological impact.

Example: U.S. EPA’s RCRA Subtitle D for solid waste containment.

Installation Guidelines

Site Preparation: Clear, grade, and compact the area.

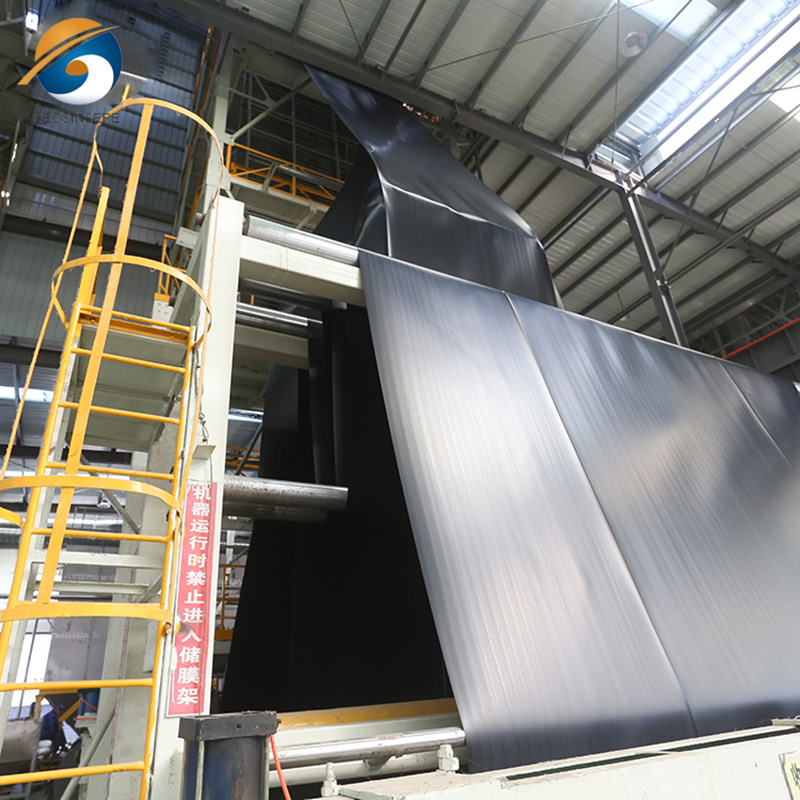

Liner Deployment: Use specialized rollers to avoid stretching or tearing.

Seaming: Use certified welders and keep seams dry and clean.

Anchor Trench: Secure liner edges in anchor trenches (typically 300–450 mm deep).

Inspection: Perform visual and NDT inspections throughout.

Covering Layer: If necessary, add a geotextile or sand layer above the liner to protect against UV and physical damage.

Performance and Lifespan

Expected lifespan: 20–50 years depending on UV exposure, chemical exposure, and physical stress.

HDPE liners in shaded or buried conditions degrade much slower than exposed ones.

Case Study: In a recent reservoir project, 1.5 mm HDPE liner maintained <1% leakage over 10 years under intense temperature variation.

Safety and Handling Considerations

Avoid installation in extreme winds or temperatures (ideal: 5–40°C).

Store rolls on dry, flat ground and away from direct sunlight.

Workers should use gloves, boots, and welding shields during seaming.

Ensure proper ventilation during welding to avoid inhaling fumes.

Frequently Asked Questions (FAQs)

Q1: What thickness should I use for a garden pond?

A: For most landscaping ponds, 1.0 mm HDPE is sufficient, but 1.5 mm is recommended for deeper or larger bodies of water.

Q2: Can HDPE liners be used under decorative gravel or stones?

A: Yes, but it's advisable to place a layer of non-woven geotextile fabric above and below the liner for protection.

Q3: Are HDPE liners safe for fish and plants?

A: Food-grade HDPE liners without toxic plasticizers are generally safe for aquatic life. Always confirm the liner is certified for environmental applications.

Q4: How are leaks detected in HDPE liners?

A: Leak location surveys can be performed using electric liner integrity testing (LIT) or air pressure tests during and after installation.

Final Thoughts

Choosing the right HDPE geomembrane liner is critical for the success and longevity of any landscaping or environmental project. From site preparation to welding and inspection, each step must be performed according to engineering and environmental standards.

Call to Action

We provide expert consultation and supply HDPE liners that meet the highest global standards. If you’re planning a landscaping project and require reliable containment solutions, contact our technical team for custom recommendations based on your project specifications.

Ensure long-term performance, ecological safety, and cost-efficiency — start your project with precision-engineered HDPE liners.