Non Woven Geotextile Drainage Fabric for Driveway

Manufacturing Process

Engineering Production Steps

Polymer chip drying and preparation

Fiber extrusion and filament formation

Web laying with controlled fiber orientation

Needle punching for mechanical bonding

Thermal setting to stabilize thickness and strength

Online inspection for mass, thickness, and uniformity

Roll cutting, labeling, and batch traceability

Key Process Controls

Consistent fiber denier for uniform permeability

Needle density control to balance strength and drainage

Strict quality testing aligned with civil engineering standards

Product Definition

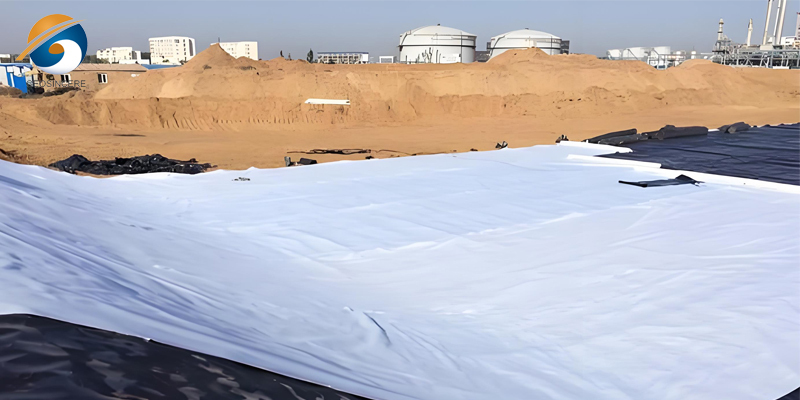

Non Woven Geotextile Drainage Fabric for Driveway is a permeable, needle-punched synthetic fabric engineered to separate soil layers, enhance drainage, and improve load distribution in driveway and access road structures. It is widely used in commercial, municipal, and infrastructure projects to extend pavement service life.

Technical Parameters and Specifications

The following parameters are commonly specified for driveway drainage and subgrade stabilization applications and are suitable for engineering design and procurement.

Raw Material: Polypropylene (PP) or Polyester (PET)

Manufacturing Method: Needle-punched non woven

Mass per Unit Area: 100–600 g/m²

Tensile Strength (MD/CD): 8–25 kN/m

Elongation at Break: 40%–80%

CBR Puncture Resistance: 1.5–6.0 kN

Water Permeability: ≥ 80 L/m²/s

Opening Size (O90): 0.08–0.20 mm

UV Resistance: ≥ 70% strength retained after 500 hours

Service Temperature: -30°C to +100°C

Structure and Material Composition

Non Woven Geotextile Drainage Fabric for Driveway is designed as a homogeneous yet highly functional structure.

Continuous Filament Fibers: Provide uniform tensile performance

Needle-Punched Matrix: Creates multidirectional drainage channels

Random Fiber Orientation: Enhances filtration and soil retention

Thermally Stabilized Surface: Improves dimensional stability during installation

Manufacturing Process

Engineering Production Steps

Polymer chip drying and preparation

Fiber extrusion and filament formation

Web laying with controlled fiber orientation

Needle punching for mechanical bonding

Thermal setting to stabilize thickness and strength

Online inspection for mass, thickness, and uniformity

Roll cutting, labeling, and batch traceability

Key Process Controls

Consistent fiber denier for uniform permeability

Needle density control to balance strength and drainage

Strict quality testing aligned with civil engineering standards

Industry Comparison

| Material Type | Non Woven Geotextile | Woven Geotextile | Gravel Only | Geogrid |

|---|---|---|---|---|

| Drainage Performance | Excellent | Moderate | Poor | Limited |

| Soil Separation | Excellent | Good | Poor | Good |

| Filtration Capability | Excellent | Limited | None | None |

| Installation Cost | Medium | Medium | Low | Medium–High |

| Driveway Suitability | Excellent | Good | Low | Supplementary |

Application Scenarios

Commercial driveway and parking access roads

Industrial facility entrances

Residential and mixed-use developments

Logistics parks and warehouse driveways

Temporary construction access roads

Core Pain Points and Solutions

Subgrade Pumping: Non woven fabric separates soil from aggregate

Water Accumulation: High permeability enables rapid drainage

Rutting and Settlement: Improved load distribution reduces deformation

Maintenance Frequency: Stabilized base extends driveway lifespan

Risk Warnings and Mitigation Recommendations

Avoid using insufficient fabric weight for heavy traffic areas

Ensure full overlap at joints (minimum 300 mm)

Prevent direct UV exposure during long storage periods

Install on properly leveled and compacted subgrade

Procurement and Selection Guide

Assess driveway traffic load and vehicle type

Determine required fabric weight and tensile strength

Evaluate soil conditions and drainage requirements

Select PP or PET based on chemical and moisture exposure

Verify laboratory test reports and compliance documents

Confirm roll dimensions and logistics compatibility

Review supplier project references and quality control system

Engineering Application Example

In a commercial logistics park project, a 300 g/m² non woven geotextile drainage fabric was installed beneath a crushed stone driveway layer over soft subgrade soil. The system significantly reduced water retention and rutting, maintaining structural integrity under continuous truck traffic for over four years.

Frequently Asked Questions

Why use non woven geotextile for driveways? It provides superior drainage and filtration.

What fabric weight is typical? 200–400 g/m² for most commercial driveways.

Can it handle heavy vehicles? Yes, when properly specified.

Is it suitable for wet soils? Yes, it performs well in saturated conditions.

Does it replace gravel? No, it works in combination with aggregate.

How long does it last? Typically 25+ years underground.

Is overlapping required? Yes, overlaps ensure continuity.

Can it be cut on site? Yes, using standard cutting tools.

Does it resist chemicals? Polypropylene offers excellent chemical resistance.

Is installation complex? No, standard civil installation methods apply.

CTA – Commercial Inquiry

For pricing, technical datasheets, or project-specific samples of Non Woven Geotextile Drainage Fabric for Driveway applications, please submit your project requirements to receive professional technical and procurement support.

E-E-A-T Author Credentials

This article is prepared by civil engineering material specialists with over 15 years of experience in geosynthetics, supporting contractors, EPC firms, and infrastructure developers in roadway and ground stabilization projects worldwide.