HDPE Geo Membrane Impermeable Liner 1.5 mm

HDPE geological membrane impermeable liner, with a thickness of 1.5 millimeters, is a thin film made of high-density polyethylene material, which has excellent impermeability, chemical resistance, and durability. It is widely used in various engineering projects, such as landfills, sewage treatment plants, reservoirs, canals, and basements, to prevent liquid leakage or infiltration. The thickness of this pad is 1.5 millimeters, providing sufficient strength and durability to withstand various environmental conditions and mechanical stresses. It also has good UV resistance and can prevent degradation caused by sunlight exposure.

High-Density Polyethylene (HDPE) geomembrane liners have become a global standard in environmental containment and civil engineering projects. Among them, the 1.5 mm HDPE geomembrane liner is widely regarded for its balance of strength, flexibility, and impermeability. This article explores its technical properties, engineering applications, installation guidelines, regulatory compliance, and answers to common user questions.

What Is a 1.5 mm HDPE Geomembrane?

Definition and Material Composition

A 1.5 mm HDPE geomembrane is a synthetic liner made from high-density polyethylene resin. It features excellent chemical resistance, UV stability, and mechanical strength, making it ideal for long-term containment solutions.

Material: High-Density Polyethylene (≥ 97.5% polymer content)

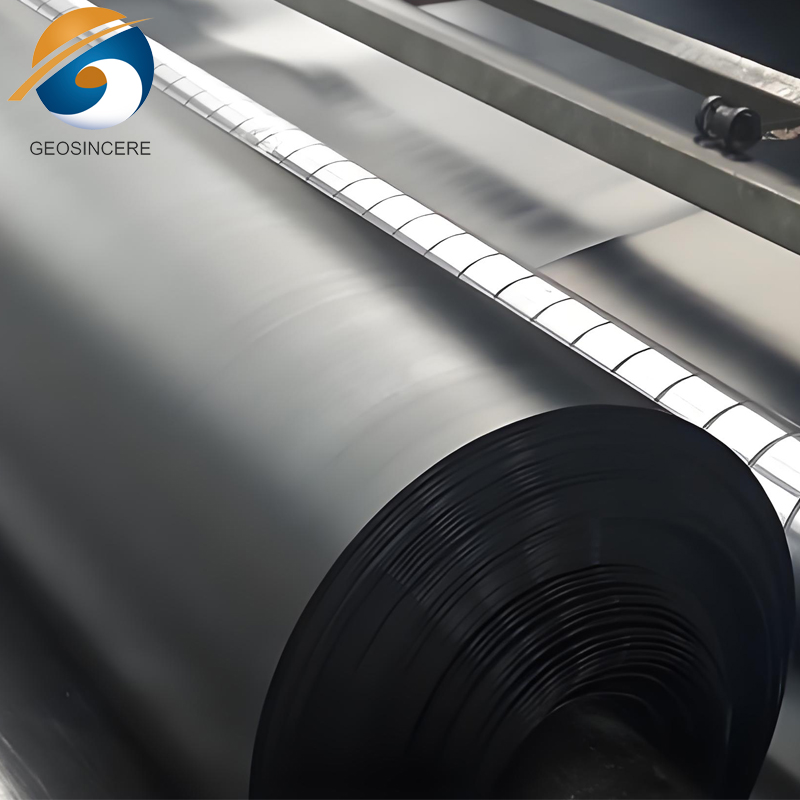

Thickness: 1.5 mm (± 0.05 mm)

Standard Width: 5.8–8.0 meters

Color: Usually black with optional textured or smooth surface

Key Features and Engineering Properties

| Property | Value | Standard |

|---|---|---|

| Tensile Strength at Yield | ≥ 20 kN/m | ASTM D638 |

| Tear Resistance | ≥ 250 N | ASTM D1004 |

| Puncture Resistance | ≥ 500 N | ASTM D4833 |

| Carbon Black Content | 2.0–3.0% | ASTM D4218 |

| Water Vapor Transmission | ≤ 1.0 x 10⁻¹³ g·cm/cm²·s·Pa | ASTM E96 |

Applications of 1.5 mm HDPE Geomembrane

1. Landfills and Solid Waste Management

Base liners and capping systems

Complies with EPA Subtitle D regulations

2. Mining Industry

Heap leach pads

Tailings storage facilities

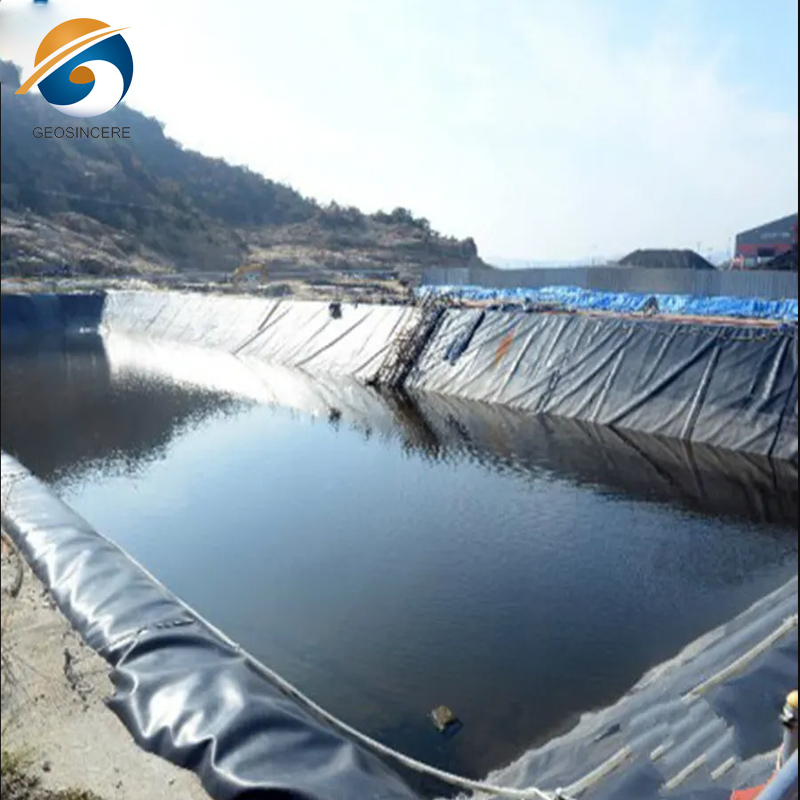

3. Aquaculture and Water Containment

Reservoirs, irrigation ponds, and fish farms

Ensures zero leakage and safe water storage

4. Petrochemical and Industrial Usage

Secondary containment for hazardous chemicals

Acid and alkali resistance according to ISO 12960

5. Tunnels and Underground Infrastructure

Waterproofing membranes for subways and tunnels

Regulatory and Quality Standards

HDPE geomembranes are manufactured and tested under internationally recognized standards:

GM13 (by GRI – Geosynthetic Research Institute)

ISO 9001 Quality Management System

CE Certification for European markets

ASTM D5885, D4218, and D5321 for performance evaluation

Installation Considerations

Surface Preparation

Smooth, compacted subgrade with no sharp objects

Geotextile underlay is recommended to prevent puncture

Welding and Seaming

Hot wedge welding and extrusion welding are common methods

All welds must be tested using non-destructive testing (NDT), e.g., air pressure test or vacuum box method

QA/QC Requirements

On-site destructive sampling per ASTM D6392

Visual inspection for holes, wrinkles, and seam integrity

Advantages of 1.5 mm Thickness

Ideal thickness for moderate to high load applications

Balances cost-effectiveness and mechanical integrity

Easier to handle than 2.0 mm liners during installation

Limitations and Engineering Controls

Not suitable for highly irregular surfaces without support

UV exposure beyond 20+ years may require protective cover

Must comply with slope stability criteria for embankments (>3:1 slopes need textured liners)

Frequently Asked Questions (FAQ)

Is a 1.5 mm HDPE liner safe for drinking water?

Yes. When certified under NSF/ANSI 61, HDPE geomembranes can be used for potable water applications. Verify certifications before use.

How long does a 1.5 mm HDPE liner last?

Under ideal conditions, lifespan exceeds 30 years. Covered installations (e.g., in landfills or reservoirs) can exceed 50 years.

Can it withstand high temperatures?

HDPE operates efficiently between -40°C and +60°C. Beyond this, thermal expansion and brittleness may occur.

Can it be used for vertical wall lining?

Yes, but mechanical anchoring or batten systems must be implemented due to gravitational load.

Conclusion: Is a 1.5 mm HDPE Liner Right for Your Project?

The 1.5 mm HDPE geomembrane is a reliable, industry-standard solution for a broad range of civil, environmental, and industrial containment needs. With its high tensile strength, impermeability, and regulatory compliance, it offers a versatile barrier against fluid migration and contamination.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

Advantages of HDPE Geo Membrane Impermeable Liner 1.5 mm

Application of HDPE Geo Membrane Impermeable Liner 1.5 mm