Reinforced Waterproofing HDPE Geomembrane

Manufacturing Process

Engineering-Oriented Production Steps

HDPE resin formulation and reinforcement material preparation

Precision extrusion of molten HDPE layers

Inline lamination with reinforcement scrim

Calendering for thickness uniformity

Controlled cooling and stress stabilization

Automated inspection for defects and delamination

Roll cutting, labeling, and protective packaging

Key Equipment and Process Controls

Multi-layer extrusion and lamination lines

High-precision calendering rollers

Online tensile and thickness monitoring systems

Quality laboratories for mechanical and hydraulic testing

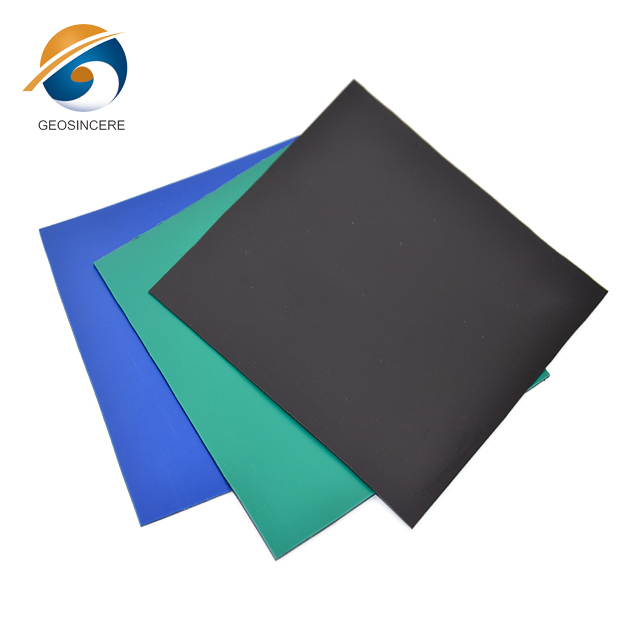

Product Definition

Reinforced Waterproofing HDPE Geomembrane is a composite impermeable lining material engineered by integrating high-density polyethylene with internal reinforcement layers. It is designed to deliver enhanced tensile strength, dimensional stability, and long-term waterproofing performance for critical containment and civil engineering projects.

Technical Parameters and Specifications

The performance of Reinforced Waterproofing HDPE Geomembrane is defined by both polymer properties and reinforcement efficiency. Typical engineering-grade specifications include:

Base Material: High-Density Polyethylene (HDPE)

Reinforcement Type: Polyester or woven geotextile scrim

Nominal Thickness: 1.0 mm – 3.0 mm

Sheet Width: 4.0 – 7.0 m

Tensile Strength (MD/TD): ≥ 20 / 20 kN/m

Elongation at Break: ≥ 400%

Hydrostatic Pressure Resistance: ≥ 0.6 MPa

Puncture Resistance: ≥ 450 N

Carbon Black Content: 2.0% – 3.0%

Design Service Life: ≥ 50 years (buried conditions)

Structure and Material Composition

Reinforced Waterproofing HDPE Geomembrane adopts a multi-layer engineered structure to balance flexibility, strength, and impermeability:

Upper HDPE Layer: Primary waterproofing and chemical barrier

Reinforcement Core: Woven or non-woven fabric providing tensile stability

Lower HDPE Layer: Enhances puncture resistance and bonding strength

Stabilizer Additives: Improve UV, oxidation, and thermal aging resistance

Manufacturing Process

Engineering-Oriented Production Steps

HDPE resin formulation and reinforcement material preparation

Precision extrusion of molten HDPE layers

Inline lamination with reinforcement scrim

Calendering for thickness uniformity

Controlled cooling and stress stabilization

Automated inspection for defects and delamination

Roll cutting, labeling, and protective packaging

Key Equipment and Process Controls

Multi-layer extrusion and lamination lines

High-precision calendering rollers

Online tensile and thickness monitoring systems

Quality laboratories for mechanical and hydraulic testing

Industry Comparison

| Material Type | Tensile Strength | Dimensional Stability | Typical Use |

|---|---|---|---|

| Reinforced HDPE Geomembrane | Very High | Excellent | Dams, tunnels, critical containment |

| Standard HDPE Geomembrane | High | Good | Landfills, ponds |

| PVC Waterproof Membrane | Medium | Moderate | Building waterproofing |

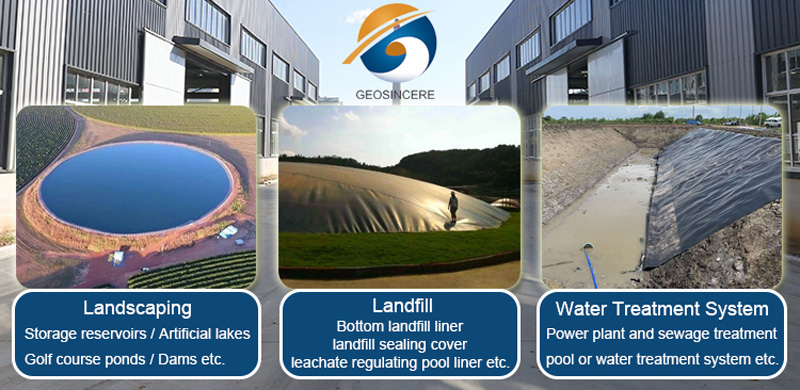

Application Scenarios

Reinforced Waterproofing HDPE Geomembrane is specified by EPC contractors, engineering consultants, and developers in:

Water reservoirs and hydraulic structures

Landfill caps and hazardous waste containment

Tunnel and underground structure waterproofing

Mining tailings storage facilities

Industrial wastewater and chemical ponds

Core Engineering Pain Points and Solutions

High Hydraulic Pressure: Reinforcement layer improves pressure resistance

Subgrade Movement: Enhanced tensile stability limits deformation

Puncture Risk: Multi-layer structure increases puncture tolerance

Long-Term Aging: HDPE formulation ensures extended service life

Risk Warnings and Mitigation Measures

Improper seam welding → Use compatible extrusion or wedge welding methods

Reinforcement exposure → Ensure complete encapsulation during manufacturing

Subgrade irregularities → Install cushioning geotextiles where required

Thermal stress during installation → Control installation temperature range

Procurement and Selection Guide

Define project waterproofing and containment objectives

Evaluate hydraulic pressure and chemical exposure levels

Select appropriate thickness and reinforcement type

Confirm compliance with ASTM or ISO standards

Assess welding method compatibility

Review supplier quality control and test reports

Verify installation support and technical documentation

Engineering Case Example

In a municipal water reservoir project, a 2.0 mm Reinforced Waterproofing HDPE Geomembrane was installed beneath a concrete lining. The reinforced structure accommodated subgrade movement while maintaining watertight integrity under sustained hydrostatic pressure.

Frequently Asked Questions (FAQ)

Q1: What differentiates reinforced HDPE geomembrane from standard HDPE?

A: Added internal reinforcement for higher tensile stability.Q2: Is it suitable for high-pressure water applications?

A: Yes, reinforcement improves pressure resistance.Q3: Can it be welded onsite?

A: Yes, using standard HDPE welding equipment.Q4: Does reinforcement reduce flexibility?

A: Slightly, but remains suitable for engineered applications.Q5: What thickness is common for reservoirs?

A: Typically 1.5–2.5 mm.Q6: Is chemical resistance affected by reinforcement?

A: No, HDPE layers provide primary resistance.Q7: Can it be used under concrete linings?

A: Yes, commonly used as a composite lining system.Q8: What is the expected service life?

A: Over 50 years under buried conditions.Q9: Is UV resistance required during storage?

A: Yes, exposure time should be controlled.Q10: Does it meet international standards?

A: Typically compliant with ASTM and ISO requirements.

Call to Action

For project-specific quotations, detailed technical datasheets, compliance certificates, or engineering samples of Reinforced Waterproofing HDPE Geomembrane, please submit a formal inquiry to receive professional technical support.

E-E-A-T Author Credentials

This technical article is authored by geosynthetics and civil engineering specialists with more than 15 years of experience in waterproofing systems, geomembrane design, and EPC infrastructure delivery, ensuring accuracy, authority, and practical relevance.