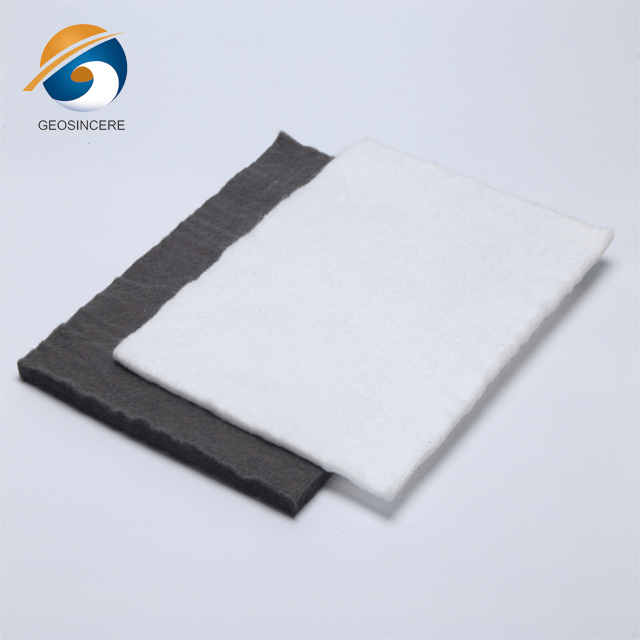

Continuous Filament Polyester Nonwoven Geotextile

Manufacturing Process

The manufacturing of Continuous Filament Polyester Nonwoven Geotextile is an integrated and highly controlled industrial process.

Engineering Production Steps

Polyester polymer melting and extrusion into continuous filaments

Filament cooling and stretching for strength development

Web formation through random filament laying

Needle punching to mechanically bond the fiber web

Heat setting for dimensional stability

Roll cutting, inspection, and batch identification

Key Manufacturing Equipment

Polyester filament spinning lines

Web forming and laying units

High-density needle punching machines

Online weight and thickness monitoring systems

Product Definition

Continuous Filament Polyester Nonwoven Geotextile is a mechanically bonded geosynthetic fabric manufactured from continuous polyester filaments, designed to provide filtration, separation, drainage, and reinforcement functions in civil, transportation, and environmental engineering applications.

Technical Parameters and Specifications

The following parameters represent commonly specified ranges for Continuous Filament Polyester Nonwoven Geotextile used in infrastructure and geotechnical engineering projects.

| Property | Typical Range | Test Standard |

|---|---|---|

| Mass per Unit Area | 100 – 800 g/m² | ASTM D5261 |

| Tensile Strength (MD/CD) | 8 – 30 kN/m | ASTM D4595 |

| Elongation at Break | 40 – 80% | ASTM D4595 |

| CBR Puncture Strength | 1.5 – 6.0 kN | ASTM D6241 |

| Permittivity | 1.0 – 3.0 s⁻¹ | ASTM D4491 |

| Apparent Opening Size (AOS) | 0.07 – 0.20 mm | ASTM D4751 |

Structure and Material Composition

Continuous Filament Polyester Nonwoven Geotextile features a uniform three-dimensional structure that enhances filtration and mechanical stability.

Polyester Continuous Filaments: Long, uninterrupted fibers for consistent strength

Needle-Punched Bonding: Mechanical interlocking without chemical binders

Isotropic Fiber Orientation: Balanced strength in machine and cross directions

High Porosity Matrix: Enables efficient water flow while retaining soil particles

Manufacturing Process

The manufacturing of Continuous Filament Polyester Nonwoven Geotextile is an integrated and highly controlled industrial process.

Engineering Production Steps

Polyester polymer melting and extrusion into continuous filaments

Filament cooling and stretching for strength development

Web formation through random filament laying

Needle punching to mechanically bond the fiber web

Heat setting for dimensional stability

Roll cutting, inspection, and batch identification

Key Manufacturing Equipment

Polyester filament spinning lines

Web forming and laying units

High-density needle punching machines

Online weight and thickness monitoring systems

Industry Comparison

| Material Type | Strength Consistency | Filtration Stability | Durability | Typical Applications |

|---|---|---|---|---|

| Continuous Filament Polyester Nonwoven Geotextile | Very High | Excellent | High | Roads, railways, drainage systems |

| Staple Fiber Nonwoven Geotextile | Moderate | Good | Moderate | General separation |

| Woven Geotextile | High | Limited | High | Reinforcement-focused projects |

Application Scenarios

Continuous Filament Polyester Nonwoven Geotextile is widely specified by EPC contractors, infrastructure developers, and consulting engineers for:

Road and highway subgrade separation

Railway ballast protection layers

Drainage systems and trench filtration

Landfill leachate collection layers

Embankment and slope stabilization

Coastal and riverbank protection works

Core Engineering Pain Points and Solutions

Soil Migration: Controlled pore structure prevents fine particle loss

Clogging Risk: High porosity improves long-term filtration performance

Uneven Load Distribution: Uniform filament network spreads stresses

Installation Damage: High puncture resistance reduces construction risk

Risk Warnings and Mitigation Measures

Improper overlap width → follow design overlap requirements

Exposure to prolonged UV → minimize storage time before installation

Incorrect grade selection → verify soil gradation and flow needs

Mechanical damage during backfilling → control fill material size

Procurement and Selection Guide

Identify functional requirement (separation, filtration, drainage)

Analyze soil particle size distribution

Select appropriate mass per unit area

Confirm tensile and puncture strength requirements

Verify compliance with project specifications

Review manufacturer quality management system

Plan installation method and site handling

Engineering Case Example

In a highway reconstruction project, Continuous Filament Polyester Nonwoven Geotextile with a mass of 300 g/m² was installed between the soft subgrade and aggregate base. The geotextile improved load distribution, prevented subgrade contamination, and enhanced long-term pavement performance under heavy traffic loads.

FAQ

Q1: What distinguishes continuous filament from staple fiber geotextiles?

A: Continuous filaments provide higher strength consistency.Q2: Is polyester suitable for wet environments?

A: Yes, polyester has excellent hydrolysis resistance.Q3: Can it be used under asphalt roads?

A: Commonly used as separation and filtration layers.Q4: Does it provide reinforcement?

A: Limited reinforcement, primarily separation and filtration.Q5: What roll widths are available?

A: Typically 4–6 meters.Q6: Is it resistant to biological degradation?

A: Yes, polyester is biologically inert.Q7: How long is the service life?

A: Often exceeds the design life of infrastructure projects.Q8: Can it be used with geogrids?

A: Yes, commonly combined in layered systems.Q9: Is on-site cutting allowed?

A: Yes, with standard cutting tools.Q10: Does it require special maintenance?

A: No, once properly installed.

Call to Action

For technical datasheets, project-specific quotations, or material samples of Continuous Filament Polyester Nonwoven Geotextile, please provide your application details, soil conditions, and required specifications for professional support.

E-E-A-T Author Credentials

This content is prepared by geotechnical engineers and geosynthetics specialists with extensive experience in transportation infrastructure, environmental engineering, and large-scale civil works, supporting informed procurement and design decisions.