Why Choose Geotextile 150g/m² and Its Applications ?

In present day civil engineering, environmental engineering, and infrastructure construction, geosynthetic substances play an more and more essential role. Among them, geotextile—a versatile and quintessential material—is broadly used for separation, filtration, drainage, and protection. In particular, the geotextile 150g/m² has end up the favored preference for many engineering initiatives due to its reasonable weight, cost-effectiveness, and huge applicability. This article presents a complete evaluation of the core fee of geotextile 150g/m², protecting cloth properties, manufacturing processes, overall performance parameters, utility areas, and decision recommendations.

1. What Is Geotextile 150g/m² ?

Geotextile 150g/m² is a medium-weight geosynthetic fabric, weighing one hundred fifty grams per rectangular meter. It is extensively used in civil engineering, avenue construction, drainage, and erosion manage tasks due to its top notch stability of strength, permeability, and cost-effectiveness. Typically, Nonwoven geotextile fabric is made from polyester (PET) or polypropylene (PP) fibers the usage of superior manufacturing methods such as needle-punching or spunbonding, which decide its structure, flexibility, and mechanical performance. This weight category is perfect for medium-load applications, together with subgrade reinforcement, filtration layers, separation of soil layers, and drainage systems.

1.1 Geotextile 150g/m² Materials and Production Processes

1.1.1 Raw Materials:

Polyester (PET): Offers excessive tensile strength, chemical resistance, UV stability, and dimensional balance below various temperatures.

Polypropylene (PP): Lightweight, flexible, resistant to acids and alkalis, and budget friendly for large-scale applications.

1.1.2 Production Processes:

- Needle-Punched Nonwoven Geotextile:

Fibers are robotically entangled the use of needles to create a dense, soft, and enormously permeable fabric.

Ideal for filtration, drainage, and soil separation, permitting water to skip thru whilst holding quality soil particles.

- Spunbond Nonwoven Geotextile:

Made by using melt-spinning polymer fibers and forming them into a non-stop web, accompanied by way of thermal bonding.

Provides greater tensile strength, uniformity, and durability, appropriate for reinforcement and load-bearing applications.

1.2 Geotextile 150g/m² Key Properties

1.2.1 Physical Properties:

Weight: 150g/m² (typically ±5% tolerance)

Thickness: 1.2–1.8mm (varies by means of manufacturing process)

Width: 2–6 meters (customizable for assignment requirements)

1.2.2 Mechanical Properties:

Tensile Strength: ≥8 kN/m (both computing device and move directions), ensuring resistance to stretching at some stage in set up and below load.

Elongation at Break: 40–80%, presenting flexibility to adapt to uneven terrain barring tearing.

CBR Puncture Resistance: ≥1.5 kN, defending the non woven landscape fabric from punctures prompted by way of gravel, stones, or machinery.

1.2.3 Hydraulic Properties:

Permeability Coefficient: ≥0.1 cm/s, permitting environment friendly water go with the flow for drainage applications.

Apparent Opening Size (AOS/O90): 0.07–0.12 mm, controlling soil particle migration and making sure advantageous filtration.

1.2.4 Durability:

Chemical Resistance: Stable in a broad pH vary of 2–12, appropriate for quite a number soil and wastewater conditions.

UV Resistance: With UV inhibitors, the non woven geotextile can ultimate over 12 months exterior at some point of installation, making sure overall performance is maintained earlier than covering.

Long-Term Performance: Resistant to microbial degradation and bodily getting older when buried, providing years of dependable carrier in infrastructure projects.

2. Core Functions of Geotextile 150g/m²

2.1 Separation

Geotextile fabric prevents intermixing of one of a kind soil layers (e.g., subsoil and fill materials), retaining the integrity and performance of every layer.

- Example Application: Prevents beaten stone from sinking into gentle subsoil when developing avenue bases, lowering fabric loss and settlement.

2.2 Filtration

Allows water to bypass whilst keeping soil particles, making sure the long-term effectiveness of drainage systems.

Example Application: Used round drainage ditches and series wells to forestall clogging by way of high-quality soil particles.

2.3 Drainage

Facilitates water waft alongside the aircraft of the non woven geotextile fabric, accelerating soil consolidation and water discharge.

Example Application: Used for slope drainage and at the back of conserving walls.

2.4 Protection

Geo fabric Acts as a protecting layer to stop geomembranes or different waterproofing substances from puncture damage.

Example Application: Used above and beneath geomembranes in landfills to furnish mechanical protection.

3. Key Application Areas of Geotextile 150g/m²

3.1 Geotextile 150g/m² for Road and Railway Engineering

- Subgrade Separation: Prevents the mixing of subsoil and gravel or mixture layers, retaining the integrity of the pavement structure. This separation improves load distribution and extends the provider lifestyles of roads and railway tracks.

- Drainage Systems: Used in shoulder drains, facet slopes, and embankment drainage layers to facilitate water flow, stop clogging, and decrease hydrostatic stress on subgrades.

- Soft Ground Improvement: When utilized over susceptible or gentle soils, the geotextile distributes masses extra evenly, improving steadiness and stopping immoderate contract beneath site visitors or rail loads.

3.2 Geotextile 150g/m² for Hydraulic Engineering

- Slope Protection: Acts as a filtration and separation layer on riverbanks, canals, or embankments to forestall soil erosion whilst permitting water to omit through.

- Reservoir Liners: Serves as a defensive and drainage layer below geomembranes, stopping punctures, retaining drainage efficiency, and prolonging liner lifespan.

- Coastal Protection: Applied in breakwaters, seawalls, and shoreline stabilization initiatives to supply filtration, guard fill materials, and stop soil washout due to wave action.

3.3 Geotextile 150g/m² for Environmental Engineering

- Landfills: Functions as a filtration layer in leachate series systems, stopping soil particles from clogging drainage pipes. Additionally, it protects geomembranes from punctures and mechanical injury at some stage in waste placement.

- Wastewater Treatment Plants: Used in sludge dewatering beds and filtration structures to separate solids from liquids, enhancing drainage effectivity and gadget performance.

3.4 Geotextile 150g/m² for Agriculture and Landscaping

- Agricultural Drainage: Enhances soil drainage in fields, stopping waterlogging, merchandising healthful root growth, and enhancing crop yield.

- Landscaping Projects: Applied in synthetic lakes, ornamental ponds, and water aspects as a filtration and protecting layer, retaining water readability and stopping soil contamination.

3.5 Geotextile 150g/m² for Construction Engineering

- Basement Waterproofing: Acts as a defensive layer for water-resistant membranes, stopping punctures and improving sturdiness throughout backfilling and construction.

- Green Roofs: Non woven geotextile membrane provides each filtration and drainage functions, defending the water-resistant membrane whilst merchandising environment friendly water administration and root aeration.

4. Key Construction Guidelines for Geotextile 150g/m²

4.1 Subgrade Preparation

- Debris Removal: Clear the building place of sharp objects such as stones, roots, and development waste to stop punctures or tears in the geotextile.

- Leveling: Grade the subgrade to do away with substantial irregularities and grant a clean floor for uniform geotextile placement.

- Pre-Compaction: For gentle or susceptible subgrades, operate pre-compaction to enhance bearing ability and decrease post-installation settlement.

4.2 Installation Methods

- Manual Installation: Suitable for small-scale or complicated projects. Workers roll out and role the geotextile, making sure minimal stretching or folding.

- Mechanical Installation: For large-scale projects, unrolling machines or conveyors can efficaciously lay geotextile panels, enhancing pace and decreasing labor costs.

- Overlap Width: Maintain an overlap of 300–500 mm between adjoining sheets to make certain non-stop insurance and stop soil intrusion.

- Seaming/Connection: Geotextile filter fabric can be joined by using hand-sewing, adhesive bonding, or specialised connectors relying on the assignment requirements.

4.3 Backfilling Requirements

- Initial Layer: Place a preliminary 300 mm layer of appropriate backfill cloth (sand, gravel, or soil) to guard the geotextile in the course of in addition operations.

- Preliminary Compaction: Use mild equipment to compact the preliminary backfill, stopping harm whilst retaining geotextile position.

- Heavy Machinery Caution: Avoid riding heavy gear without delay over the geotextile till enough backfill insurance is executed to stop tearing or displacement.

4.4 Quality Control

- Inspection: Check for any damage, holes, or infection in the geotextile fabric under gravel earlier than and after installation.

- Overlap Verification: Ensure all overlaps meet format specs and preserve continuity throughout the set up area.

- Backfill Quality: Confirm that backfill substances are free of particles and accurate compacted to reap plan density and assist performance.

5. Selection Advice and Technical Considerations for 150g/m² Geotextile

5.1 Project Evaluation Factors

Soil Conditions: Assess particle dimension distribution, permeability, compaction, and shear energy of the subgrade soil. The geotextile need to be chosen to supply advantageous separation, filtration, and reinforcement primarily based on soil characteristics.

Load Requirements: Consider static loads, dynamic loads, and visitors frequency. Medium-weight geotextiles like 150g/m² are appropriate for medium-duty roads, embankments, and drainage layers the place average load-bearing potential is required.

Environmental Factors: Evaluate conceivable publicity to chemicals, UV radiation, temperature variations, and different environmental stresses. Choose geotextiles with chemical stability, UV inhibitors, and long-term sturdiness for outside or harsh conditions.

Hydraulic Conditions: For drainage and filtration applications, examine go with the flow velocity, water stage variations, and conceivable clogging risks. Ensure permeability and opening measurement suit task necessities to hold environment friendly water go with the flow whilst maintaining soil particles.

5.2 Comparison with Other Geotextile Specifications

Parameter | 100g/m² | 150g/m² | 200g/m² |

Thickness | 0.8–1.2 mm | 1.2–1.8 mm | 1.8–2.5 mm |

Tensile Strength | 5–6 kN/m | 8–10 kN/m | 12–15 kN/m |

Permeability | Excellent | Good | Moderate |

Cost | Low | Medium | High |

Applications | Light-duty roads, landscaping | Medium-duty roads, drainage, subgrade separation | Heavy-duty roads, highways, industrial areas |

Tip: 150g/m² geotextile affords a stability between strength, permeability, and cost, making it perfect for most medium-duty engineering projects.

5.3 Certifications and Standards

International Standards: ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), EN (European Standards)

National Standards: GB/T 17638, GB/T 17639 (China)

Quality Certifications: CE Marking, ISO 9001 Quality Management System

Note: Ensure the chosen geotextile meets applicable requirements and has legitimate certifications to assurance performance, reliability, and protection in engineering applications.

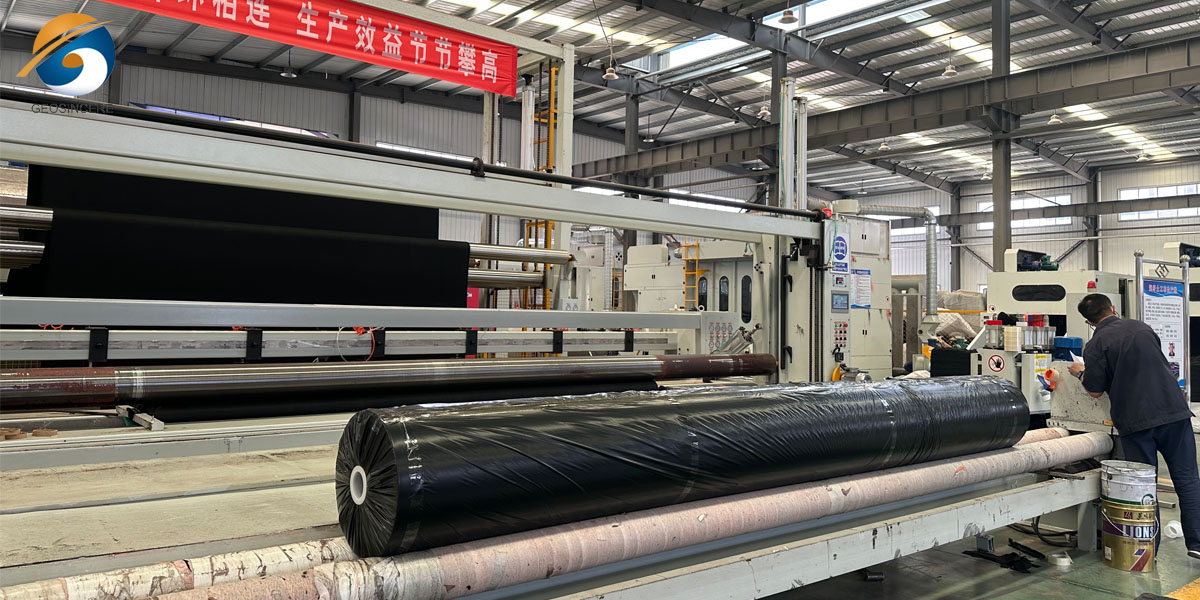

6. GEOSINCERE Geosynthetics’s Geotextile 150g/m² Solutions

As a expert geosynthetic supplier, GEOSINCERE presents complete Geotextile 150g/m² solutions:

6.1 Product Advantages

Premium Raw Materials: Virgin polyester granules make sure fabric consistency.

Advanced Manufacturing: German needle-punching manufacturing strains warranty product uniformity.

Strict Quality Control: Each roll undergoes laboratory testing.

Customization Services: Custom widths and lengths handy based totally on assignment requirements.

6.2 Technical Support and Global Service Network

GEOSINCERE Geosynthetics affords complete technical guide at some point of the lifecycle of geotextile products. Our engineering crew gives expert session to assist pick out the most appropriate geotextile based totally on undertaking requirements, soil conditions, and environmental factors. We additionally supply set up guidance, inclusive of on-site guide to make certain suitable placement, overlap, and backfilling, decreasing the danger of set up errors. Post-installation, BPM ensures full-process after-sales service, monitoring first-rate and addressing any overall performance worries promptly.

6.3 Global Service Network

In addition, GEOSINCERE Geosynthetics keeps a international provider community to aid worldwide tasks efficiently. Our manufacturing bases are strategically positioned in foremost cities throughout China, complemented with the aid of bonded warehouses in key world regions. Through partnerships with main delivery companies, we make sure well timed and dependable logistics, whilst nearby carrier retailers in over 50 nations furnish on-the-ground support, technical assistance, and quickly shipping to meet mission deadlines.

7. Frequently Asked Questions

7.1 What is the service life of Geotextile 150g/m²?

Under standard conditions, the design service life exceeds 25 years. Actual lifespan depends on environmental conditions and installation quality.

7.2 How to evaluate geotextile quality?

Key indicators include weight tolerance, tensile strength, tear resistance, permeability coefficient, and UV stability.

7.3 Is geotextile recyclable?

Polypropylene geotextiles are recyclable, while polyester geotextiles require special processing.

7.4 What are common installation errors?

Insufficient overlap width.

Poor subgrade preparation.

Backfill containing sharp objects.

Direct operation of heavy machinery on the geotextile.

8. Conclusion

The geotextile 150g/m² , as an economical and practical geosynthetic material, plays an irreplaceable role in modern engineering construction. Its excellent functions in separation, filtration, drainage, and protection make it an ideal choice for roads, railways, water conservancy projects, environmental engineering, and more. Through proper selection and standardized installation, this material significantly enhances project quality, extends service life, and reduces maintenance costs.

Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) is committed to providing customers with the highest-quality geotextile products and professional technical services. If you have any questions or requirements regarding 150g/m² geotextile, please contact our technical team for comprehensive support.