High Performance Geotextile Fabric for Road Covering

High-performance geotextile materials can be widely used as roadbed covering materials in highway projects. This fabric product has excellent tensile strength, high wear resistance and good water permeability, which can effectively reduce roadbed settlement and improve the overall stability of the highway. During the paving process, high-performance geotextiles can also isolate soil particles between the roadbed and the covering layer, preventing fine particles from entering the pavement layer and causing early damage. At the same time, the excellent water permeability of this material can also help to drain the water accumulated in the roadbed in time, avoiding the problem of freezing and thawing of the road surface caused by water accumulation. Therefore, using high-performance geotextiles as roadbed covering materials in highway projects can effectively improve the service life and reliability of the highway.

Road construction and maintenance require more than just asphalt and concrete. Beneath every smooth and durable surface lies a foundation that must withstand pressure, moisture, and time. That’s where High Performance Geotextile Fabric for Road Covering comes into play—a smart, engineered solution that significantly extends road life, improves drainage, and reduces maintenance costs.

Whether you’re building highways, rural roads, parking lots, or access tracks, choosing High Performance Geotextile Fabric for Road Covering is an investment in performance and long-term success.

What Is High Performance Geotextile Fabric for Road Covering?

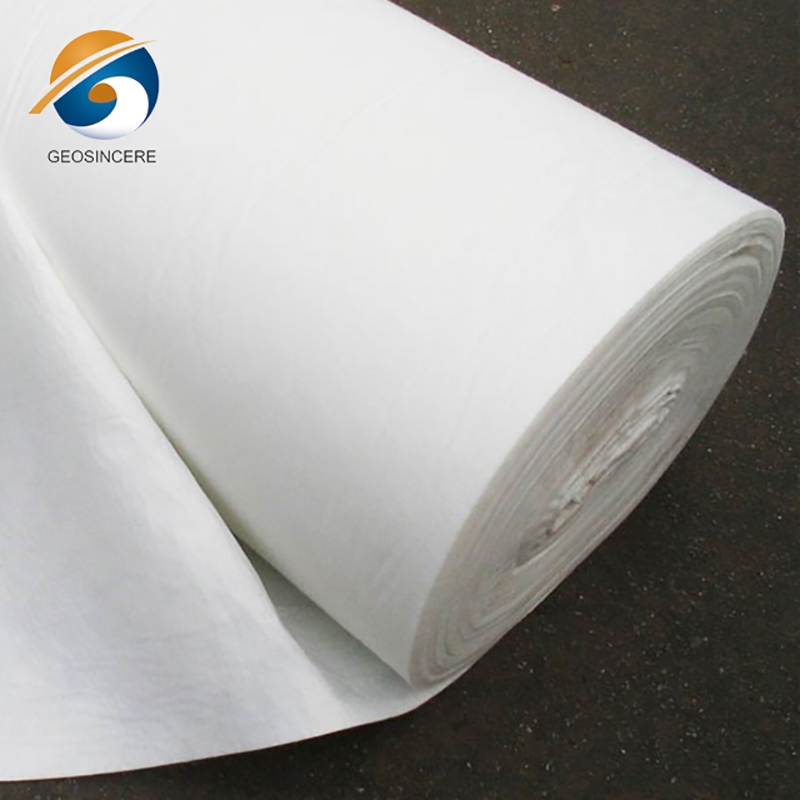

High Performance Geotextile Fabric for Road Covering is a woven or non-woven geosynthetic fabric engineered for civil construction applications. It’s designed to separate, reinforce, filter, and drain under layers of aggregate, subbase, and pavement.

By acting as a stable barrier between subgrade and base layers, High Performance Geotextile Fabric for Road Covering prevents soil migration, controls erosion, and distributes loads—dramatically enhancing the structural integrity of roads and highways.

Why You Need High Performance Geotextile Fabric for Road Covering

1. Extended Road Lifespan

Without proper separation, base layers mix with the underlying soil, causing early road failure. High Performance Geotextile Fabric for Road Covering creates a durable, stable barrier that preserves the integrity of base materials, preventing rutting, cracking, and potholes.

🛣️ Result: Roads last longer, perform better, and require fewer repairs.

2. Exceptional Load Distribution

In heavy traffic areas, pressure from above must be evenly distributed to prevent deformation below. The tensile strength of High Performance Geotextile Fabric for Road Covering helps distribute weight across a broader area, minimizing stress on weak subgrades.

This is especially vital for roads built over soft, expansive, or unstable soils.

3. Moisture Management & Drainage

Water is the enemy of any pavement structure. High Performance Geotextile Fabric for Road Covering offers high permeability, allowing water to pass through while filtering out fine particles. This maintains base course strength and prevents saturation-related failures.

💧 Stay dry, stay strong: Moisture-controlled roads experience significantly fewer structural issues.

4. Reduced Construction Costs

By reinforcing the roadbed and minimizing aggregate loss, High Performance Geotextile Fabric for Road Covering reduces the need for thick layers of expensive fill materials. Faster installation and longer-lasting performance mean fewer resources over time.

💰 Bottom line: Save on labor, materials, and long-term maintenance.

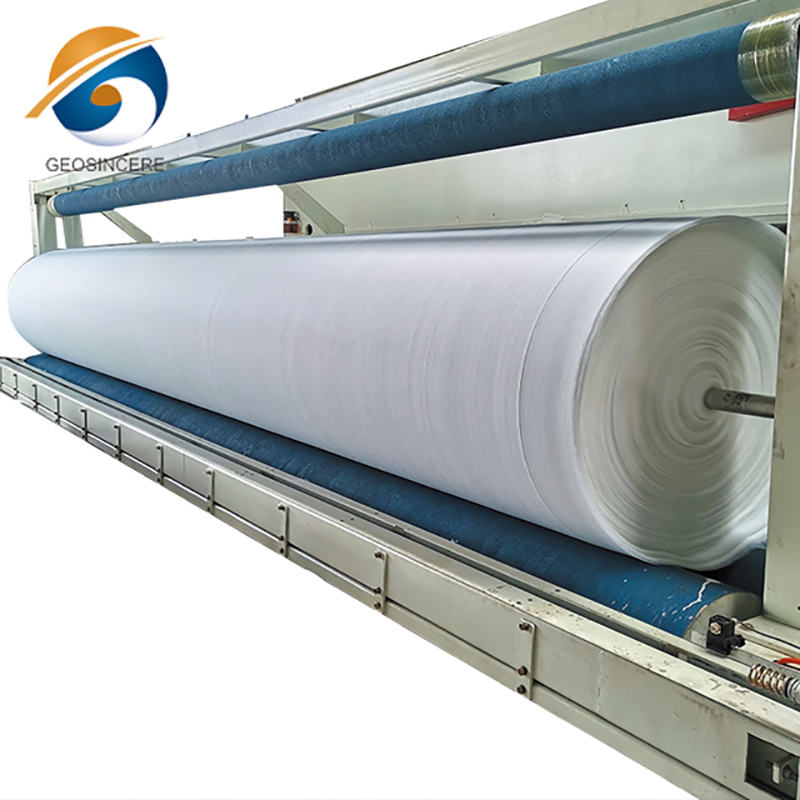

5. Easy to Install, Easy to Maintain

Lightweight and roll-form, High Performance Geotextile Fabric for Road Covering is simple to handle and install. No heavy machinery or complex tools required. It unrolls easily over the subgrade and is immediately ready for aggregate placement.

Whether you're managing a large-scale highway project or rural access road, installation is efficient and reliable.

Ideal Applications for High Performance Geotextile Fabric for Road Covering

Urban and rural road construction

Parking lot subgrade stabilization

Driveways and access roads

Logging and haul roads

Airport runways and taxiways

Railway ballast support

Cold climate pavement reinforcement

How to Select the Right Geotextile Fabric

Not all geotextiles are created equal. When selecting a High Performance Geotextile Fabric for Road Covering, consider:

Tensile strength and elongation

Puncture resistance and tear strength

Water permeability rate

Soil retention and filtration efficiency

UV stability for exposed applications

Certification (ASTM, ISO, AASHTO compliant)

Partnering with a reliable geotextile manufacturer ensures you get performance-tested materials suitable for your specific site conditions.

Environmental and Sustainability Benefits

Modern infrastructure must be both resilient and environmentally responsible. High Performance Geotextile Fabric for Road Covering reduces aggregate consumption, prevents soil erosion, and extends the service life of paved surfaces—reducing the environmental footprint of road construction projects.

Some fabrics are made from recycled materials and offer reduced carbon emissions compared to traditional road-building methods.

Final Thoughts

If you're looking to build roads that last, cut maintenance costs, and enhance overall performance, High Performance Geotextile Fabric for Road Covering is an indispensable part of your toolkit. It’s not just a layer—it's the foundation of smarter, stronger, and more sustainable infrastructure.

Ready to Reinforce Your Roads?

Contact a trusted supplier today and discover how High Performance Geotextile Fabric for Road Covering can transform your next road project into a high-performance, low-maintenance success story.