Custom Anti UV Salt Pond Liner Waterproof Geomembrane

In recent years, the global geomembrane market has seen significant growth, largely driven by increasing demand from aquaculture, salt production, and environmental protection industries. The custom anti-UV salt pond liner waterproof geomembrane has become an essential material for managing water containment systems exposed to high salinity and UV radiation. According to industry reports, the geomembrane market is projected to exceed USD 3.5 billion by 2030, with Asia-Pacific and the Middle East leading in consumption due to rapid infrastructure development and coastal resource utilization.

Buyers worldwide are now prioritizing high-quality HDPE and LLDPE geomembranes with enhanced UV resistance and long-term chemical stability. These features are particularly critical for salt ponds, where intense sunlight and saline environments can quickly degrade inferior materials.

Global Demand for Anti-UV Salt Pond Liner Waterproof Geomembranes

In recent years, the global geomembrane market has seen significant growth, largely driven by increasing demand from aquaculture, salt production, and environmental protection industries. The custom anti-UV salt pond liner waterproof geomembrane has become an essential material for managing water containment systems exposed to high salinity and UV radiation. According to industry reports, the geomembrane market is projected to exceed USD 3.5 billion by 2030, with Asia-Pacific and the Middle East leading in consumption due to rapid infrastructure development and coastal resource utilization.

Buyers worldwide are now prioritizing high-quality HDPE and LLDPE geomembranes with enhanced UV resistance and long-term chemical stability. These features are particularly critical for salt ponds, where intense sunlight and saline environments can quickly degrade inferior materials.

Material Composition and Technical Specifications

The custom anti-UV salt pond liner waterproof geomembrane is typically made from high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE). The incorporation of anti-UV additives and carbon black significantly enhances its resistance to photo-oxidation, extending its lifespan even under prolonged exposure to harsh sunlight.

Common technical parameters include:

• Thickness range: 0.5mm–2.0mm

• Tensile strength: ≥25 MPa

• Elongation at break: ≥700%

• UV aging resistance: ≥8000 hours

• Water permeability: ≤1.0×10⁻¹³ cm/s

These performance indicators ensure that the geomembrane maintains superior flexibility, puncture resistance, and watertight integrity in long-term applications. Custom options allow for additional features such as textured surfaces for slope stability and co-extruded layers for enhanced sealing.

Manufacturing Process and Quality Control

High-quality anti-UV geomembranes are produced using advanced three-layer co-extrusion blown film or flat die extrusion processes. The raw materials are precisely blended with anti-UV agents and antioxidants before extrusion. Each sheet undergoes rigorous mechanical testing, including tear strength, hydrostatic pressure resistance, and environmental stress cracking tests.

Modern production lines are equipped with automatic thickness control and online inspection systems to ensure uniformity. The resulting geomembrane offers consistent performance and dimensional stability, which are critical for large-area installations in salt ponds or water retention projects.

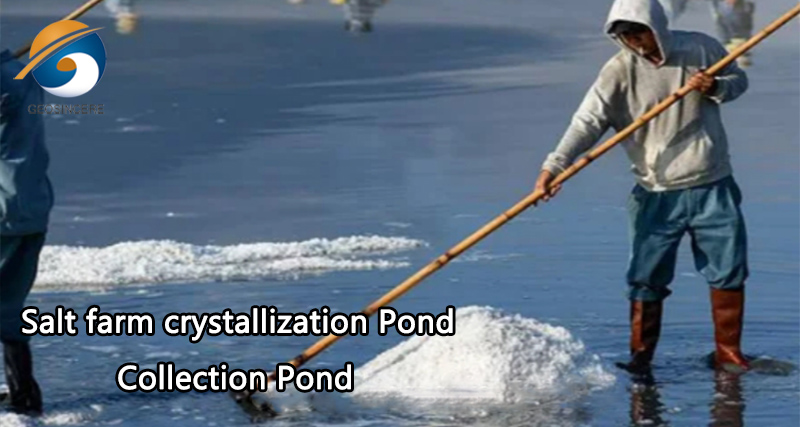

Applications in Salt Pond and Aquaculture Projects

Custom anti-UV salt pond liner waterproof geomembranes are extensively used in salt evaporation ponds, aquaculture tanks, fish farms, shrimp ponds, and chemical containment basins. In salt production, the geomembrane serves as a reliable waterproof barrier, preventing salt loss and groundwater contamination while facilitating efficient salt crystallization.

For aquaculture, the liner ensures stable water quality, minimizes seepage, and protects against soil-borne contaminants. The anti-UV properties are particularly valuable in tropical regions where sunlight intensity accelerates material degradation. Properly installed liners can last up to 20 years with minimal maintenance.

Global Market Trends and Buyer Preferences

International buyers are increasingly emphasizing product customization and environmental compliance. Sustainable materials and ISO-certified production are now key purchasing factors. Buyers prefer suppliers that offer geomembranes with verifiable ASTM, GRI-GM13, or CE certifications to ensure compatibility with international construction standards.

Another growing trend is the shift toward prefabricated panels and welded rolls, which reduce on-site labor costs and installation errors. Buyers also value transparent pricing models and technical support for installation design, seam welding, and post-installation inspection.

Pricing Factors for Waterproof Geomembrane Sheets

The price of a custom anti-UV salt pond liner waterproof geomembrane is influenced by multiple factors, including raw material quality, thickness, UV resistance, and order volume. Typically, the cost ranges from USD 1.5 to 3.5 per square meter depending on specifications and logistics. Long-term buyers often prioritize consistency and performance over price alone, as inferior materials can lead to costly repairs and environmental risks.

Challenges and Solutions in International Procurement

Buyers often face challenges such as limited supplier transparency, inconsistent testing data, and shipping delays. Working directly with manufacturers that maintain in-house quality testing laboratories and international logistics partnerships ensures stable supply chains and verified product compliance.

We provide comprehensive documentation including material test reports, installation manuals, and performance warranties to support clients in project tendering and quality audits.

Frequently Asked Questions (FAQ)

1. What is the typical lifespan of an anti-UV salt pond geomembrane?

With proper installation and maintenance, the geomembrane can last 15–20 years, even in extreme sunlight and saline conditions.

2. Can the liner be customized for specific pond dimensions?

Yes. We offer custom sizes, thicknesses, and edge welding to fit your pond layout and minimize on-site seams.

3. How does UV resistance affect performance?

Anti-UV additives prevent polymer degradation caused by ultraviolet radiation, ensuring long-term flexibility and structural integrity.

4. What documentation is available for international buyers?

We provide test reports, quality certificates, and technical datasheets compliant with ASTM and ISO standards.

Professional Consultation and Sample Request

For engineers, contractors, and procurement managers seeking reliable waterproof solutions for salt ponds or aquaculture projects, our custom anti-UV geomembrane products deliver consistent performance and cost efficiency. Contact our technical team today to request detailed specifications, quotation sheets, and material samples tailored to your project needs.

Our commitment is to supply durable, certified, and competitively priced geomembrane liners that enhance project sustainability and operational longevity.