Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank

The global adoption of Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank solutions has increased rapidly as aquaculture expands to meet rising global seafood demand. Industry studies show that aquaculture now delivers more than half of the world’s aquatic protein supply. This shift has intensified demand for engineered lining materials capable of ensuring water stability, reducing leakage, improving feed efficiency, and preventing environmental contamination in both inland and coastal farming systems.

Geomembranes have become the preferred material for modern aquaculture infrastructure. Their impermeability, mechanical durability, and chemical resistance are critical for constructing fish ponds, shrimp tanks, biofloc tanks, and recirculating aquaculture system (RAS) reservoirs. Market reports from leading regions—Southeast Asia, Africa, Latin America, and the Middle East—indicate strong growth in polymer-based containment materials, particularly in operations requiring long service life with minimal maintenance.

Global Market Background for Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank

The global adoption of Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank solutions has increased rapidly as aquaculture expands to meet rising global seafood demand. Industry studies show that aquaculture now delivers more than half of the world’s aquatic protein supply. This shift has intensified demand for engineered lining materials capable of ensuring water stability, reducing leakage, improving feed efficiency, and preventing environmental contamination in both inland and coastal farming systems.

Geomembranes have become the preferred material for modern aquaculture infrastructure. Their impermeability, mechanical durability, and chemical resistance are critical for constructing fish ponds, shrimp tanks, biofloc tanks, and recirculating aquaculture system (RAS) reservoirs. Market reports from leading regions—Southeast Asia, Africa, Latin America, and the Middle East—indicate strong growth in polymer-based containment materials, particularly in operations requiring long service life with minimal maintenance.

Global Trends Shaping Aquaculture Lining Materials

Three dominant global trends are affecting market demand. First, water resource efficiency has become essential amid climate variability, pushing operators toward pond liners that minimize seepage losses. Second, biosecurity concerns in intensive aquaculture drive the adoption of materials that prevent disease transfer through soil and groundwater. Third, the shift toward RAS and modular farming systems favors flexible and customizable liners, which can be deployed quickly and reshaped as operations expand.

Long-tail terms such as “aquaculture geomembrane liner”, “HDPE fish pond lining sheet”, “plastic tank liner roll”, “geomembrane for shrimp farming”, and “pond waterproofing membrane” reflect rising search volume from commercial buyers evaluating material performance before procurement.

Technical Specifications and Performance Requirements

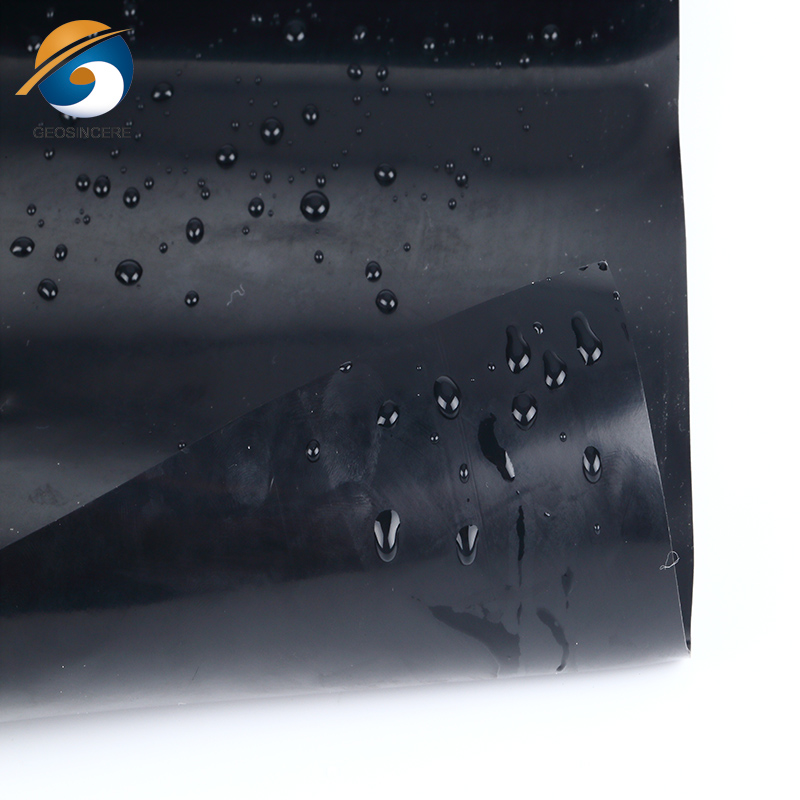

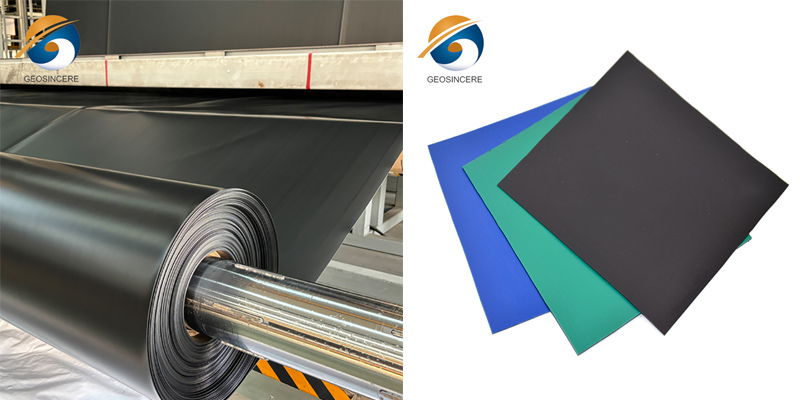

A high-quality Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank liner must deliver exceptional impermeability, tensile strength, and resistance to UV exposure. Typical material thickness ranges from 0.5 mm to 2.0 mm depending on tank size and operating environment. In outdoor tanks exposed to sunlight, UV-stabilized formulations significantly enhance product lifetime, often exceeding 7–15 years with proper installation.

Main technical parameters include tensile strength at yield and break, puncture resistance, tear resistance, hydrostatic resistance, elongation, and carbon black distribution uniformity. Surface texture options—smooth or embossed—support friction performance in sloped tanks and reduce installation sliding risks. Permeability rates as low as 1×10⁻¹³ to 1×10⁻¹⁴ m/s ensure water retention efficiency, especially in arid-climate aquaculture projects.

Material Structure and Composition

The structure of an aquaculture geomembrane typically consists of a uniform polyethylene or polyolefin sheet reinforced with stabilizers, antioxidants, and UV-protection additives. Carbon black is incorporated into outdoor-rated films to resist photooxidation. For operations using saline or brackish water, the geomembrane’s chemical resistance to salts, ammonia, organic acids, and disinfectants is essential for long-term tank stability.

Some advanced liners integrate multi-layer co-extrusion, combining a core structural layer with protective surfaces engineered for abrasion resistance. These features support heavy feed loads, fish movement, tank cleaning procedures, and mechanical stress caused by aeration systems.

Manufacturing Process and Quality Control

The production process commonly involves blown-film or flat-die extrusion, ensuring consistent thickness and mechanical uniformity. Raw resin is melted, homogenized, filtered, extruded, cooled, and rolled into continuous sheets suitable for onsite welding. Precision extrusion lines use automatic gauge control systems to maintain dimensional tolerances critical for engineering performance.

Quality control involves rigorous testing protocols: oxidative induction time (OIT), dimensional checks, environmental stress crack resistance (ESCR), puncture resistance, and elongation testing. International buyers frequently request compliance documentation such as ISO physical property tests, ASTM standards for geomembrane performance, and application-specific lab reports relevant to aquaculture environments.

Applications in Modern Aquaculture Systems

The Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank system is widely used in fish ponds, shrimp grow-out tanks, hatcheries, RAS reservoirs, broodstock ponds, and temporary farming units. Its flexibility enables rapid assembly in both circular and rectangular tank designs. In developing regions, geomembranes support community-level aquaculture clusters by providing cost-effective water containment solutions.

In intensive biofloc systems, liners prevent nutrient-rich water from infiltrating the soil, maintaining stable biofloc concentration and preventing contamination. In hatcheries, geomembranes facilitate easy cleaning and high hygiene control. For large commercial farms, the liners reduce maintenance downtime and enhance water retention efficiency, directly improving fish growth rates and feed conversion ratios.

Global Buyer Preferences and Procurement Challenges

International buyers prioritize performance reliability, compliance certifications, and scalability. Common purchasing preferences include:

• Customizable sheet widths and roll lengths to reduce welding time

• UV-stabilized materials suitable for long-term outdoor exposure

• High puncture and tear resistance to support large tank operations

• Technical guidance for installation and on-site seam welding

However, buyers frequently encounter challenges such as variable product quality among suppliers, insufficient technical documentation, inconsistent thickness tolerance, and inadequate packaging leading to transport-related deformation. Transparent specifications and consistent quality control remain critical for supplier selection.

Market Outlook and Strategic Importance

The global market for Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank products will continue expanding as aquaculture gains prominence in global food security strategies. Governments and private investors are funding inland aquaculture, shrimp farming, and recirculating systems, driving long-term demand for durable and cost-effective lining materials. As operational efficiency and sustainability requirements intensify, engineered geomembranes will remain central to advanced aquaculture infrastructure.

Frequently Asked Questions (FAQ)

Q1: What thickness is recommended for commercial aquaculture tanks?

A: For medium to large tanks, 0.75–1.5 mm thickness is common, depending on tank size, water volume, and intended lifespan.

Q2: Are geomembrane liners suitable for saltwater aquaculture?

A: Yes. High-quality polyethylene geomembranes provide excellent resistance to saltwater, ammonia, and common aquaculture disinfectants.

Q3: How long can a UV-stabilized liner last outdoors?

A: With proper installation, UV-stabilized liners typically perform for 7–15 years depending on climate exposure.

Q4: Can rolls be customized for large tank construction?

A: Yes. Many suppliers provide custom-width rolls to minimize welding and accelerate installation.

For technical data sheets, engineering consultation, or tailored quotations for Plastic Sheeting Roll Pool Liner Geomembrane Aquaculture Tank systems, we invite you to contact our team. We provide sample evaluation, project-specific guidance, and complete support for commercial aquaculture development.