Geomembrane Liner Landfill

Driven by tightening environmental regulations and rising waste volumes, the global demand for geomembrane liner landfill systems continues to expand steadily. The industry has observed a notable shift toward engineered barrier materials designed to meet stricter compliance requirements under international standards. The increasing adoption of geomembrane liners in municipal solid waste facilities, mining tailings, industrial waste containment, and hazardous waste cells reflects the growing emphasis on long-term environmental safety.

The geomembrane market has experienced consistent growth over the past five years, supported by infrastructure investments in developing regions, upgrading of aging landfill systems in mature markets, and expanding applications beyond landfills. As landfill operators face heightened scrutiny regarding groundwater contamination and leachate control, geomembrane liner landfill solutions have become a critical component of modern waste management infrastructure.

Global Market Landscape for Geomembrane Liner Landfill Systems

Driven by tightening environmental regulations and rising waste volumes, the global demand for geomembrane liner landfill systems continues to expand steadily. The industry has observed a notable shift toward engineered barrier materials designed to meet stricter compliance requirements under international standards. The increasing adoption of geomembrane liners in municipal solid waste facilities, mining tailings, industrial waste containment, and hazardous waste cells reflects the growing emphasis on long-term environmental safety.

The geomembrane market has experienced consistent growth over the past five years, supported by infrastructure investments in developing regions, upgrading of aging landfill systems in mature markets, and expanding applications beyond landfills. As landfill operators face heightened scrutiny regarding groundwater contamination and leachate control, geomembrane liner landfill solutions have become a critical component of modern waste management infrastructure.

Technical Structure and Engineering Composition

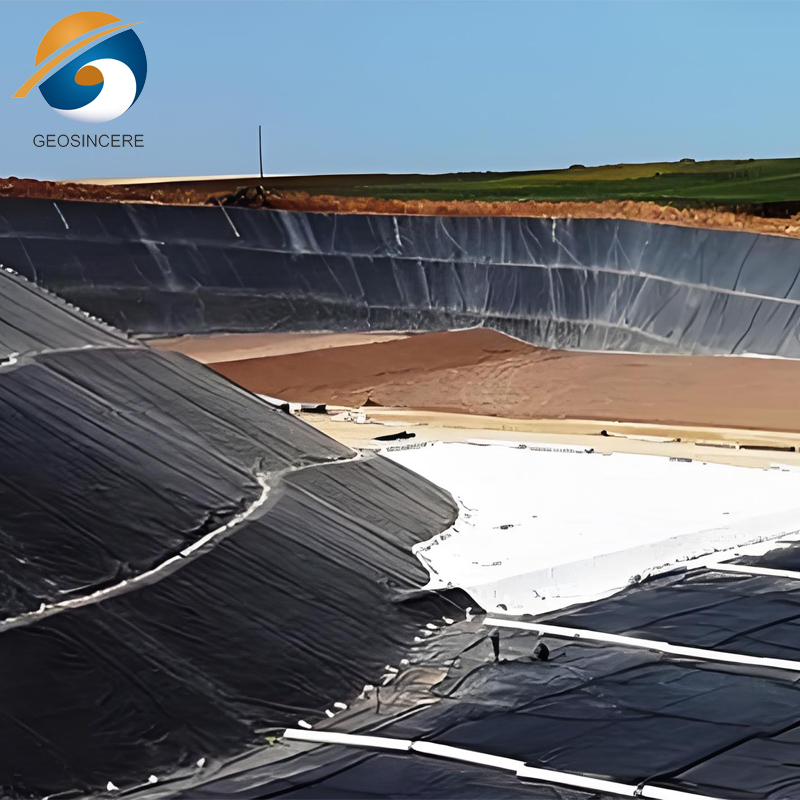

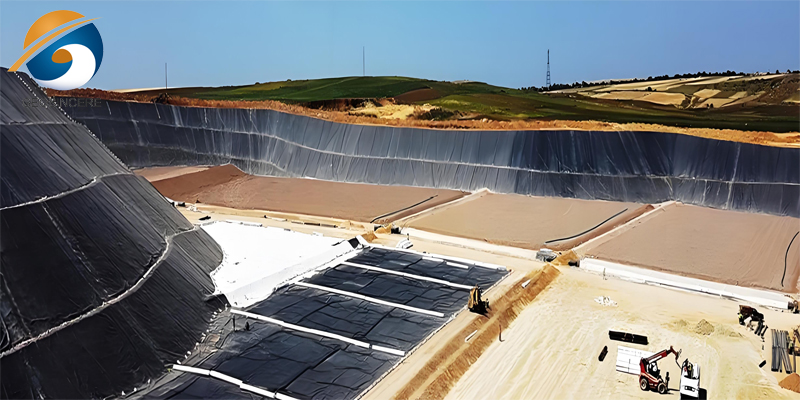

A typical geomembrane liner landfill system integrates multiple engineered layers designed to deliver impermeability, chemical resistance, and long-term durability. The liner is generally composed of high-density polyethylene (HDPE), offering outstanding tensile strength and resistance to UV exposure and chemical degradation. Key design attributes include thickness consistency, carbon-black content, elongation properties, and stress-crack resistance, all of which contribute to performance over decades of field use.

The geomembrane liner is installed over a compacted subgrade or geosynthetic clay liner, functioning as the primary barrier preventing leachate migration. The interface friction, seam weld quality, and surface texture are critical parameters influencing overall containment performance, especially on steep landfill side slopes or irregular base grades.

Manufacturing Process and Quality Control Standards

Geomembrane liner landfill materials undergo a precise extrusion or blown-film manufacturing process to ensure uniformity and mechanical stability. Each production batch incorporates rigorous inspection, including resin verification, melt-flow index testing, thickness measurement, puncture resistance evaluation, and destructive seam testing. Global standards such as GRI-GM13, ISO 9001, and ASTM guidelines define the acceptable performance thresholds for material durability and environmental resistance.

In large-scale projects, quality assurance extends to on-site procedures such as field seam welding, vacuum testing, air-channel trial verification, and non-destructive shear testing. These steps ensure that the geomembrane liner landfill installation meets regulatory requirements and performs reliably under changing environmental stresses.

Market Trends and Industry Outlook

Several key trends are shaping the global geomembrane liner landfill sector. First, the shift toward thicker liners and textured surfaces reflects the rising need for enhanced slope stability and extended service life. Second, sustainability goals are accelerating interest in multi-layer composite systems that integrate geomembranes with GCL or drainage geonets. Third, digital inspection tools and automated welding equipment are transforming field installation practices, improving precision and reducing human error.

Emerging markets in Southeast Asia, Africa, and Latin America show strong demand for geomembrane liner landfill projects as governments expand waste management infrastructure. Meanwhile, North America and Europe continue upgrading existing landfills to meet stricter environmental compliance standards. These developments collectively contribute to a robust and growing global market outlook.

Buyer Preferences and Procurement Considerations

International buyers prioritise several core factors when sourcing geomembrane liner landfill materials. Material certification, traceability of resin source, and consistent mechanical properties remain top concerns. Buyers also expect comprehensive technical documentation, including test reports, installation guidelines, and QC inspection records. In large landfill cells, procurement decisions increasingly favour suppliers with proven track records in complex engineering projects and the capability to deliver customized liner geometries.

The most common pain points for buyers include unpredictable delivery timelines, insufficient after-sales technical support, and inconsistent quality among batches. Buyers also seek reliable welding accessories, on-site technical assistance, and real-time progress reporting during installation. Addressing these challenges allows suppliers to build trust and enhance long-term cooperation in international markets.

Applications and Performance Expectations

Geomembrane liner landfill systems are deployed in a wide range of applications including municipal solid waste cells, hazardous waste containment structures, mining leach pads, and evaporation ponds. In each scenario, the geomembrane serves as the critical environmental barrier preventing leachate infiltration and protecting groundwater resources.

Performance expectations have increased significantly as landfill operators prioritize higher durability, reduced maintenance, and extended service life. Mechanical robustness, chemical compatibility, and long-term stress-crack resistance are essential benchmarks used by engineers and regulators worldwide.

Conclusion and Industry Outlook

The geomembrane liner landfill sector will continue to expand as global environmental regulations intensify and waste management infrastructure evolves. With advanced manufacturing standards, improved engineering design, and rising demand from emerging economies, high-performance geomembrane liners remain indispensable for modern landfill construction.

We support international buyers in evaluating technical specifications, identifying optimal liner configurations, and meeting compliance requirements. Buyers seeking detailed pricing, engineering data, material samples, or project consultations are encouraged to connect with our team for a tailored quotation and professional guidance.

FAQ

What is the recommended thickness for a geomembrane liner landfill system?

Thickness varies by regulatory requirements and site conditions, but HDPE liners between 1.5 mm and 2.0 mm are commonly specified for municipal and industrial landfills.

How long can a geomembrane liner landfill system last?

With proper installation and high-quality material, service life can exceed 30 years, depending on UV exposure, chemical contact, and operational load.

Do textured geomembranes offer better performance on slopes?

Yes. Textured geomembranes significantly enhance frictional resistance, improving stability on steep landfill slopes and irregular surfaces.

Can buyers request customized roll widths or project-specific specifications?

Yes. Custom configurations, technical adaptations, and engineered designs can be produced to meet specific landfill requirements and regulatory standards.

For pricing details, engineering consultation, or material samples for your upcoming geomembrane liner landfill project, contact us to receive a tailored quotation and full technical dossier.