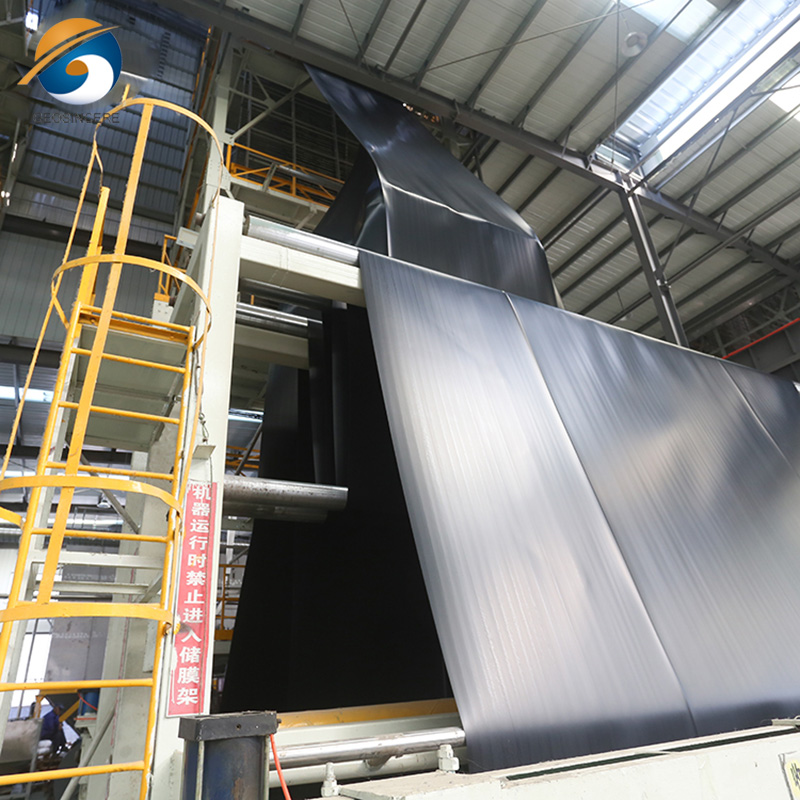

Resistance UV Waterproof Geomembrabe Liner for Salt Industry

Waterproof geotextile liner that blocks ultraviolet rays is a crucial material in the salt industry, specifically designed to address common challenges in salt field environments. This type of geomembrane is usually made of high-density polyethylene (HDPE) and is widely used due to its excellent durability and corrosion resistance. Its main function is to provide an effective waterproof barrier, preventing water infiltration and pollutants from entering the salt field, thereby protecting the purity and quality of the salt. In addition, its UV resistance enables it to withstand direct sunlight exposure, avoiding material failure caused by UV degradation and significantly extending its service life. In the application of salt industry, this geomembrane can not only improve production efficiency, but also effectively reduce environmental impact, ensuring the friendliness of the production process to the natural ecology. Overall, waterproof geomembranes that block ultraviolet radiation are essential key materials in modern salt production, providing solid support for salt field operations.

In the harsh, saline, and highly UV-exposed environments of the salt industry, ensuring long-term containment and evaporation efficiency requires specialized materials. A Resistance UV Waterproof Geomembrane Liner is engineered to meet these unique demands, delivering robust performance in salt pans, brine ponds, and crystallization beds. This article offers a comprehensive, technically detailed exploration of geomembrane liners specifically designed for the salt industry, focusing on their materials, UV resistance, waterproofing capabilities, installation, and relevant industry standards.

What Is a Resistance UV Waterproof Geomembrane Liner?

A geomembrane liner is a low-permeability synthetic membrane used to control fluid migration. For salt industry use, these liners are typically manufactured from UV-stabilized High-Density Polyethylene (HDPE) or Linear Low-Density Polyethylene (LLDPE)—materials known for their chemical resistance, impermeability, and UV durability.

Key Characteristics:

UV Resistance: >80% retention after 20,000 hours of accelerated UV testing

Salt Resistance: Chemically inert against NaCl, MgCl₂, and other brine components

Waterproofing: Hydraulic conductivity < 1×10⁻¹³ cm/s

Service Life: 20–30 years in exposed outdoor salt field applications

Applications in the Salt Industry

Salt Crystallization Beds

Prevents salt loss through infiltration

Enhances yield by promoting uniform brine evaporation

Brine Evaporation Ponds

Maintains chemical stability of brine solution

Minimizes contamination of surrounding soils or groundwater

Leachate and Wastewater Containment

Used for managing saline wastewater during salt refinement

Lining of Salt Storage Areas

Prevents groundwater contamination and salt leaching

Material Composition and Technical Specifications

| Component | Specification | Standards |

|---|---|---|

| Base Material | HDPE or LLDPE | ASTM D1505, ISO 1133 |

| Thickness Range | 0.75 mm – 2.5 mm | ASTM D5199 |

| UV Stabilizer Content | ≥2.0% (Carbon Black or HALS) | ASTM D4218 |

| Tensile Strength | ≥28 MPa | ASTM D638 |

| Elongation at Break | ≥700% (LLDPE), ≥450% (HDPE) | ASTM D6693 |

| Puncture Resistance | ≥500 N | ASTM D4833 |

| Seam Strength | ≥90% of parent material | ASTM D6392 |

| Chemical Resistance | Stable in high-saline, acidic, and alkaline environments | ASTM D543 |

Engineering Considerations in Design

1. UV Exposure & Longevity

Salt fields are typically located in high solar irradiance regions. Geomembranes must incorporate carbon black dispersion or Hindered Amine Light Stabilizers (HALS) to prevent polymer chain degradation.

2. Chemical Compatibility

Brine and associated compounds like CaCl₂, KCl, MgSO₄ demand materials with exceptional chemical inertness. HDPE outperforms PVC or EVA in such scenarios.

3. Surface Friction & Wind Uplift

Open salt pans are susceptible to wind. Use of textured geomembranes improves interlayer friction and reduces slippage or uplift during strong gusts.

4. Thermal Expansion

Daily temperature swings affect liner dimension. Use LLDPE liners where flexibility under stress is required.

Installation Guidelines for Salt Fields

Subgrade Preparation

Compact surface to 95% Proctor density

Remove all sharp objects and irregularities

Deployment

Panels unrolled during early morning or late afternoon to minimize thermal tension

Overlaps: Minimum 100 mm side, 150 mm end

Seaming

Dual-track hot wedge welding

Field seams must be tested using air channel or vacuum box method

Ballasting and Protection

Use sandbags or protective geotextiles to anchor liner edges against wind

Optional: Cover exposed areas with reflective white geomembranes to reduce thermal aging

Standards and Regulatory Guidelines

ASTM D5883 – Geomembrane seam strength evaluation

GSI-GM13 – HDPE geomembrane specification by Geosynthetic Institute

ISO 9862 / 9863 – Determination of thickness and mass per unit area

GB/T 17643-2011 – Chinese standard for composite geomembranes

ISO 9001 / CE Certification – Manufacturing quality compliance

Case Example: Salt Pan Project in Coastal Gujarat, India

Material Used: 1.5 mm UV-resistant HDPE geomembrane

Area Covered: 120,000 m²

Results:

Brine leakage reduced by 99.7%

Harvest cycle efficiency improved by 18%

10-year service life with no visual degradation

Frequently Asked Questions

Q1: What is the minimum thickness for salt field applications?

A: A minimum thickness of 1.0 mm is recommended, but 1.5 mm is standard for long-term UV exposure.

Q2: Can these geomembranes be installed during high temperatures?

A: Yes, but welding efficiency drops above 45°C ambient. Install early morning and test every seam.

Q3: Are black geomembranes better for UV resistance?

A: Yes. Black geomembranes with carbon black content (≥2%) offer the highest UV protection among all colors.

Q4: How are defects in field seams detected?

A: Non-destructive air channel testing and vacuum box testing (ASTM D5820) are standard for on-site verification.

Conclusion

Resistance UV Waterproof Geomembrane Liners are indispensable for the salt industry, offering unmatched performance in seepage control, UV resistance, and chemical stability. When specified and installed correctly, they dramatically extend the operational life of salt pans and reduce maintenance costs.

Engineers and operators must select certified materials and follow rigorous quality control during installation. For long-term brine containment and salt recovery efficiency, a well-designed geomembrane system is not a luxury—it is a necessity.