LLDPE Geomembrane Pond Liner 500 micron Price

LLDPE geomembrane pond liner 500 micron price has become a key reference point for international buyers as global water management, aquaculture, mining and environmental engineering projects expand rapidly. The surge in infrastructure upgrades, agricultural water storage and industrial containment applications is pushing worldwide demand for durable, cost-effective geomembrane liners. As governments and private developers invest more heavily in sustainable water systems, the requirement for robust 500-micron LLDPE pond liners has increased significantly.

Recent market data shows the geomembrane industry is growing at 7%–9% annually, with LLDPE liners gaining market share due to their balance of flexibility, tensile strength and competitive pricing. Regions such as Southeast Asia, Africa and Latin America are experiencing accelerated adoption because of rising aquaculture capacity and a shift toward engineered pond construction. Consequently, interest in consistent LLDPE geomembrane pond liner 500 micron price benchmarks has grown, influencing procurement strategies worldwide.

Global Demand for LLDPE Geomembrane Pond Liner 500 Micron Price Continues to Rise

LLDPE geomembrane pond liner 500 micron price has become a key reference point for international buyers as global water management, aquaculture, mining and environmental engineering projects expand rapidly. The surge in infrastructure upgrades, agricultural water storage and industrial containment applications is pushing worldwide demand for durable, cost-effective geomembrane liners. As governments and private developers invest more heavily in sustainable water systems, the requirement for robust 500-micron LLDPE pond liners has increased significantly.

Recent market data shows the geomembrane industry is growing at 7%–9% annually, with LLDPE liners gaining market share due to their balance of flexibility, tensile strength and competitive pricing. Regions such as Southeast Asia, Africa and Latin America are experiencing accelerated adoption because of rising aquaculture capacity and a shift toward engineered pond construction. Consequently, interest in consistent LLDPE geomembrane pond liner 500 micron price benchmarks has grown, influencing procurement strategies worldwide.

Industry Background and Market Trends

LLDPE geomembrane is valued for its chemical resistance, UV stability and adaptability in complex pond structures. Unlike HDPE, which prioritizes stiffness, LLDPE offers higher elongation, making it more suitable for uneven foundations and curved pond designs. These advantages are driving increased use across aquaculture farms, irrigation reservoirs, wastewater treatment systems and landfill protection zones.

The global trend toward climate-resilient agriculture and controlled aquaculture is reshaping material preferences. Buyers increasingly focus not only on LLDPE geomembrane pond liner 500 micron price, but also on certification, lifespan and installation efficiency. Digital procurement, quality traceability and custom-size production are now standard expectations in international markets.

Technical Specifications of 500 Micron LLDPE Geomembrane

The performance of a 500-micron liner is defined by key engineering parameters that determine suitability for water retention and environmental containment. Typical specifications include:

Thickness and Density

The nominal thickness of 500 microns (0.5 mm) meets the durability requirements for medium-duty pond applications. LLDPE’s density of 0.915–0.935 g/cm³ enhances flexibility while maintaining structural integrity.

Tensile Strength

Linear low-density polyethylene provides tensile strength typically between 12–30 MPa, ideal for ponds exposed to settlement or minor substrate movement.

Elongation at Break

Elongation often exceeds 700%, offering superior adaptability to uneven terrain compared to stiffer HDPE alternatives. This minimizes stress cracking and ensures long-term reliability.

UV and Chemical Resistance

UV-stabilized formulations improve outdoor lifespan, while chemical resistance supports applications in wastewater ponds, industrial containment and aquaculture systems exposed to feed additives or disinfectants.

Structure and Production of LLDPE Pond Liners

LLDPE geomembrane pond liner 500 micron price is influenced by production methods and raw material grades. Manufacturing typically involves:

Blown Film Extrusion

Raw polymer pellets are melted, extruded and inflated into tubular films. This process ensures uniform thickness distribution and high tensile strength across the sheet.

Multi-Layer Co-Extrusion (Optional)

Some manufacturers utilize three-layer structures to enhance UV resistance, tear strength and environmental durability. Inner layers provide elasticity, while outer layers offer protective resistance.

Corona Treatment and Surface Finishing

Surface treatment increases liner friction, reducing slippage during installation and improving bonding performance in certain applications.

Throughout production, quality control measures such as thickness measurement, carbon-black dispersion testing and mechanical performance evaluation ensure consistency before export.

Common Applications of 500 Micron LLDPE Pond Liners

The 500-micron specification is widely used in medium-duty containment systems across multiple industries. Key applications include:

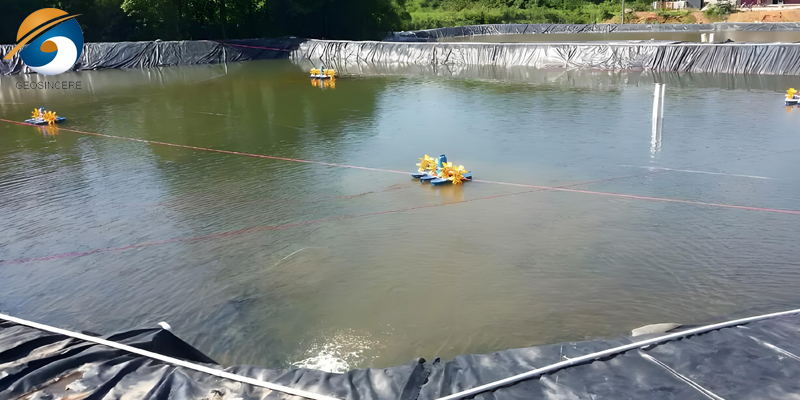

• Aquaculture fish ponds and shrimp farms

• Agricultural irrigation reservoirs

• Industrial and municipal wastewater treatment ponds

• Decorative garden ponds and landscape water features

• Mining process water containment

• Landfill leachate channels and secondary barriers

Each application demands consistent puncture resistance, impermeability and UV stability—factors that shape international buyers’ purchasing decisions.

Factors Influencing LLDPE Geomembrane Pond Liner 500 Micron Price

The market price is shaped by several global and production-related factors:

• Raw material costs driven by global polyethylene pricing

• Carbon-black content and UV-stabilizer formulation level

• Manufacturing technology (single-layer vs. co-extrusion)

• Roll width customization and non-standard sizing

• Export logistics, freight rates and regional taxation

• Required certifications such as ISO, ASTM or local engineering standards

As buyers evaluate LLDPE geomembrane pond liner 500 micron price, many prioritize overall lifecycle cost rather than only upfront pricing. The shift toward durability-focused procurement is especially visible in aquaculture projects with long-term operational cycles.

Global Buyer Preferences and Procurement Pain Points

International buyers consistently emphasize delivery reliability, inspection transparency and technical documentation. Their most common procurement expectations include:

• Accurate thickness consistency across all rolls

• Verified mechanical performance backed by test reports

• Stable lead times and predictable production schedules

• Customized roll lengths to reduce on-site welding

Buyers’ pain points typically involve inconsistent thickness, insufficient UV stability, lack of certifications, or long shipping delays during peak seasons. As a result, many large-scale projects now require pre-shipment inspection, digital QA tracking and engineering support during liner selection.

Conclusion: Demand for 500-Micron LLDPE Pond Liners Will Continue Expanding

As global water management and aquaculture systems expand, demand for reliable and competitively priced liners will continue rising. LLDPE geomembrane pond liner 500 micron price remains a critical factor for both small and large procurement teams, but long-term durability, technical compliance and service support are increasingly shaping purchase decisions.

We support international buyers with technical data sheets, sample evaluation and customized project specifications. For detailed pricing, application consultation or engineering guidance, we welcome inquiries from contractors, distributors and project consultants.

FAQs

1. What is the typical lifespan of a 500-micron LLDPE pond liner?

Lifespan ranges from 8–15 years depending on installation quality, UV exposure and soil conditions.

2. Can a 500-micron liner be used for commercial aquaculture ponds?

Yes. It provides adequate durability, flexibility and impermeability for fish and shrimp farming systems.

3. Are customized roll widths available?

Yes. Custom widths up to 8 meters are typically available to reduce field welding.

4. How can I get an exact quotation?

Quotation depends on thickness accuracy, roll dimensions, order volume and shipping destination. Contact us for detailed pricing and technical documentation.

For engineering support, material samples or the latest LLDPE geomembrane pond liner 500 micron price, please reach out to request a professional quotation.