Geomembrane Waterproofing 1mm HDPE Liner

The global market for Geomembrane Waterproofing 1mm HDPE Liner has expanded rapidly due to increasing regulatory pressure on environmental protection, large-scale infrastructure development, and rising demand for efficient waterproofing solutions. As governments strengthen groundwater protection policies and industrial sectors adopt sustainable engineering practices, the need for reliable HDPE geomembrane systems continues to grow across Asia-Pacific, North America, the Middle East, Latin America, and parts of Europe.

Industry figures from international environmental engineering associations indicate robust year-over-year growth driven by applications in landfill capping, mining containment, agricultural ponds, wastewater treatment, and reservoir construction. High-density polyethylene liners have become an essential component in modern geotechnical engineering thanks to their durability, chemical resistance, and long-term impermeability.

Introduction: Growing Global Demand for 1mm HDPE Geomembrane Waterproofing Liner

The global market for Geomembrane Waterproofing 1mm HDPE Liner has expanded rapidly due to increasing regulatory pressure on environmental protection, large-scale infrastructure development, and rising demand for efficient waterproofing solutions. As governments strengthen groundwater protection policies and industrial sectors adopt sustainable engineering practices, the need for reliable HDPE geomembrane systems continues to grow across Asia-Pacific, North America, the Middle East, Latin America, and parts of Europe.

Industry figures from international environmental engineering associations indicate robust year-over-year growth driven by applications in landfill capping, mining containment, agricultural ponds, wastewater treatment, and reservoir construction. High-density polyethylene liners have become an essential component in modern geotechnical engineering thanks to their durability, chemical resistance, and long-term impermeability.

Global Market Overview and Key Growth Drivers

The Geomembrane Waterproofing 1mm HDPE Liner market is experiencing an estimated CAGR of 7%–10%, supported by infrastructure spending and stricter environmental compliance requirements. Demand is particularly strong in regions with rapid industrial expansion, where leakage control and soil protection remain top priorities. Long-tail keywords such as “HDPE liner for landfill projects”, “1mm geomembrane for aquaculture ponds”, “waterproofing membrane for reservoirs”, and “geomembrane lining system installation” show rising search volume as buyers worldwide seek credible technical insights.

Mining, waste management, agriculture, energy, and public infrastructure represent the major downstream sectors. With global awareness shifting toward long-term environmental safety and the prevention of groundwater contamination, 1mm HDPE liners have become a strategic choice for engineers and procurement teams.

Technical Specifications and Performance Indicators

Geomembrane Waterproofing 1mm HDPE Liner is designed to provide robust barrier performance with consistent physical and mechanical properties. Standard international specifications include:

• Thickness: 1.0 mm (±0.03 mm depending on production standards)

• Density: ≥0.94 g/cm³

• Tensile strength at yield: ≥18 MPa

• Tensile strength at break: ≥25 MPa

• Elongation at break: ≥700%

• Tear resistance: ≥250 N

• Carbon black content: 2%–3%

• Puncture resistance: ≥400 N

These parameters ensure a high-performing waterproofing barrier suitable for multi-industry applications. Compared with thinner liners, the 1mm type offers balanced mechanical strength, flexibility, and installation efficiency, making it a preferred choice for medium-to-large containment projects.

Product Structure and Engineering Characteristics

The material structure of the Geomembrane Waterproofing 1mm HDPE Liner consists of high-density polyethylene resin blended with antioxidants, UV stabilizers, and carbon black. This formulation ensures long-term weather resistance, mechanical endurance, and chemical stability. The liner’s molecular structure provides high resistance to cracking, stress deformation, and corrosive environments.

Its low permeability performance is critical for preventing liquid migration in applications such as landfills and wastewater facilities. Additionally, HDPE geomembranes exhibit excellent compatibility with a variety of soils and geotextile layers, making them adaptable for composite lining systems.

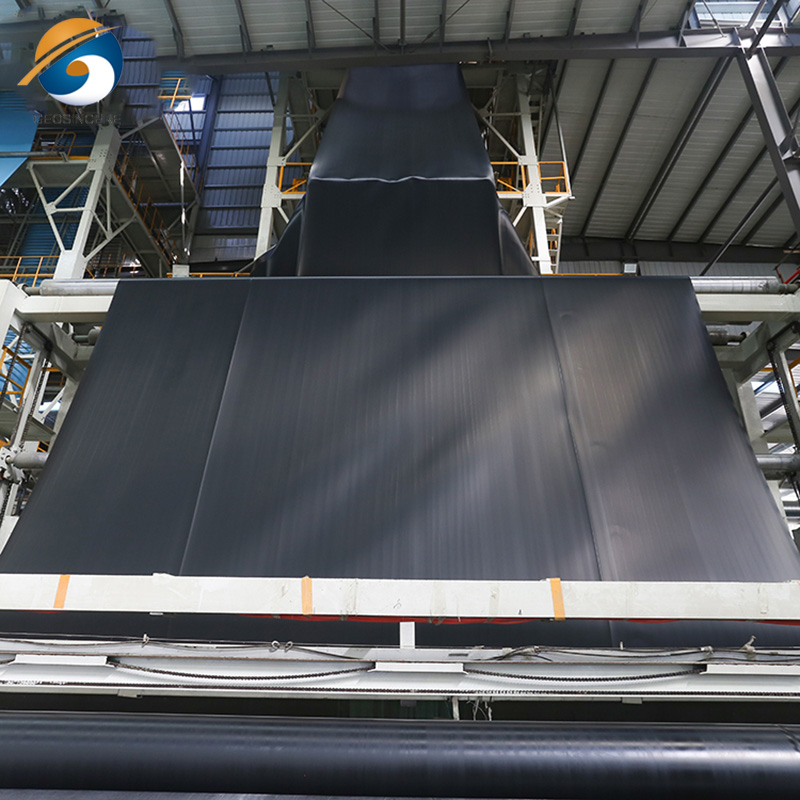

Manufacturing Process and Quality Control Standards

The production of Geomembrane Waterproofing 1mm HDPE Liner involves precision extrusion and strict quality monitoring to ensure consistency across wide-width rolls. A standard manufacturing workflow includes:

1. Resin selection and pellet inspection

2. Extrusion blowing or flat die extrusion

3. Thickness calibration and surface texture adjustment (smooth or textured options)

4. Continuous cooling and stabilized shaping

5. Surface inspection, pinhole testing, and mechanical property evaluations

6. Automated cutting, rolling, packaging, and shipment preparation

International buyers often request ASTM, GRI-GM13, or ISO test reports to verify liner integrity. Compliance with these standards reflects high manufacturing consistency and long-term field performance.

Industry Trends: What’s Driving Buyer Decisions in 2025

Several industry trends are shaping procurement strategies for 1mm HDPE geomembranes:

• Increasing adoption of textured liners for slope stability in mining and embankment projects

• Growing preference for large-width rolls to improve installation efficiency

• Rising demand for high-UV-resistant liners suited for desert and high-temperature regions

• Expansion of aquaculture projects requiring safe and long-lasting pond liners

• Greater emphasis on traceable product documentation and performance certification

These evolving requirements reflect the global shift toward risk-controlled engineering and sustainable environmental management.

International Buyer Preferences and Procurement Challenges

While demand for Geomembrane Waterproofing 1mm HDPE Liner continues to grow, buyers often face common challenges during procurement:

• Variability in liner thickness accuracy from some suppliers

• Unclear quality documentation or absence of third-party compliance testing

• Concerns about UV resistance for long-term outdoor exposure

• Inconsistent roll lengths leading to installation delays

• Limited technical support for welding procedures and leak detection systems

To address these issues, We recommend requesting complete technical data sheets, GRI-GM13 compliance reports, project references, and installation guidelines before finalizing procurement decisions.

Applications Across Global Engineering Projects

The Geomembrane Waterproofing 1mm HDPE Liner is widely used across environmental, industrial, and agricultural sectors. Key applications include landfill base liners, tailings dams, stormwater ponds, irrigation canals, aquaculture ponds, wastewater lagoons, chemical containment areas, and reservoir waterproofing. Its balance of mechanical strength and cost efficiency makes it one of the most frequently specified waterproofing membranes in large international projects.

Conclusion: A Reliable Waterproofing Solution for Global Projects

As global infrastructure modernization continues, the importance of high-performance waterproofing solutions becomes increasingly evident. Geomembrane Waterproofing 1mm HDPE Liner provides long-lasting protection, chemical resilience, and efficient installation across diverse industries. With growing regulatory requirements, international buyers prioritize consistent quality, certified performance, and strong technical support.

If you need project-based recommendations, engineering samples, or detailed quotations, We can provide technical documents, customized specifications, and professional consultation tailored to your application.

FAQs

1. What is the expected service life of a 1mm HDPE geomembrane?

Under proper installation and exposure conditions, the service life commonly exceeds 20–30 years due to strong UV and chemical resistance.

2. Can 1mm HDPE liners be welded on-site?

Yes. They are typically welded using hot wedge or extrusion welding, ensuring a secure and leak-proof connection.

3. Is a smooth or textured liner better?

Smooth liners are ideal for pond and reservoir applications, while textured liners are preferred for slopes requiring higher friction and stability.

4. What documents should buyers request before shipment?

Common documents include thickness test reports, tensile test results, carbon black measurements, GRI-GM13 compliance statements, and roll inspection records.

Sources referenced: Geosynthetic Research Institute (GRI), ISO 10319 tensile testing standards.