Custom Geosynthetic Composite Geomembrane Landfill Liner

The global demand for custom geosynthetic composite geomembrane landfill liner has surged over the past decade as governments tighten regulations on waste containment, industrial wastewater control, and environmental protection. This liner type, combining geomembrane with geotextile or other reinforcement layers, has become the preferred solution for landfill projects seeking durability, chemical resistance, and long-term stability.

According to multiple international environmental engineering reviews, geosynthetics consumption continues to grow at 6%–8% annually, driven by infrastructure upgrades, land remediation, and the rising need for secure waste disposal in developing economies.

Global Market Landscape for Custom Geosynthetic Composite Geomembrane Landfill Liner

The global demand for custom geosynthetic composite geomembrane landfill liner has surged over the past decade as governments tighten regulations on waste containment, industrial wastewater control, and environmental protection. This liner type, combining geomembrane with geotextile or other reinforcement layers, has become the preferred solution for landfill projects seeking durability, chemical resistance, and long-term stability.

According to multiple international environmental engineering reviews, geosynthetics consumption continues to grow at 6%–8% annually, driven by infrastructure upgrades, land remediation, and the rising need for secure waste disposal in developing economies.

Industry Trends and Market Drivers

Several key trends are shaping the adoption of custom geosynthetic composite geomembrane landfill liner across global markets. First, landfill operators increasingly prioritize low-permeability barriers that maintain integrity under heavy loads and harsh chemical exposure. Second, engineering consultants prefer customizable composite structures that reduce installation time while improving tensile strength.

Additionally, sustainability policies from major economies are accelerating the transition toward engineered landfill containment systems that rely heavily on composite geomembranes, particularly in hazardous and municipal waste management applications.

Technical Specifications and Material Structure

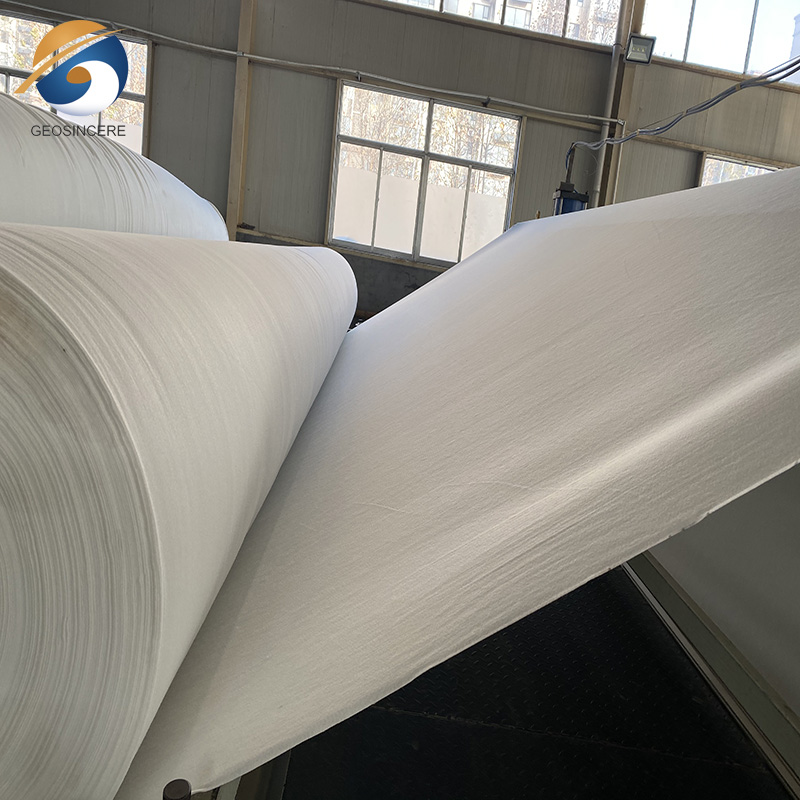

A typical custom geosynthetic composite geomembrane landfill liner integrates a high-grade polyethylene geomembrane bonded to non-woven geotextile or other reinforcing layers. This configuration enhances puncture resistance, interface friction angle, anti-seepage performance, and long-term durability.

Key parameters include thickness (commonly 1.5–2.5mm), tensile strength, elongation at break, tear resistance, carbon black content, UV stability, and permeability coefficients. The composite layer, whether geotextile or reinforced fiber, improves anti-slip behavior during slope installation while offering additional protection against mechanical damage.

Manufacturing and Lamination Process

The production of a custom geosynthetic composite geomembrane landfill liner involves precision extrusion of polyethylene resin followed by thermal bonding or adhesive lamination with the selected geotextile. Quality control includes resin filtration, surface inspection, weldability testing, and hydrostatic performance verification.

Every batch undergoes mechanical strength testing and anti-aging evaluation to ensure compliance with international landfill engineering standards.

Application Scenarios in Landfill Engineering

The custom geosynthetic composite geomembrane landfill liner is widely used in municipal solid waste landfills, hazardous waste containment cells, industrial tailings storage, sludge ponds, and leachate collection zones. Its composite structure ensures high friction strength on slopes, preventing liner slippage during construction.

Beyond landfills, engineers apply these liner systems to mining operations, chemical evaporation ponds, and water reservoir sealing projects where long-term impermeability is essential.

Global Buyer Preferences and Procurement Pain Points

International buyers sourcing custom geosynthetic composite geomembrane landfill liner consistently highlight several priorities: certified raw materials, customized thickness options, verified mechanical properties, and competitive lead times. Many purchasing teams also emphasize the importance of project-specific laminations, accurate roll dimensions, and strong documentation for compliance audits.

Common pain points include inconsistent product quality across suppliers, insufficient traceability, inadequate test reports, and logistics delays for large-volume shipments. As environmental regulations intensify, buyers expect reliable manufacturing processes and full technical support, including installation guidance and weld testing recommendations.

Why Composite Liner Customization Matters

Customization enables engineers to tailor the liner’s performance characteristics to site-specific challenges such as steep slopes, aggressive chemical exposure, or high mechanical stress. By adjusting geotextile weight, geomembrane thickness, and bonding methods, the final composite system provides superior resistance to damage and extended service life.

For landfill operators, a custom geosynthetic composite geomembrane landfill liner translates into improved containment integrity and lower long-term maintenance risk.

Conclusion, FAQ, and Professional Call-to-Action

As landfill engineering standards elevate globally, the custom geosynthetic composite geomembrane landfill liner continues to play a critical role in ensuring environmental protection and operational reliability. Buyers seeking durable, high-performance containment systems increasingly rely on composite solutions that combine mechanical strength with proven impermeability.

We provide technical support, specification customization, and sample services for international engineering projects. To receive a quotation, datasheet package, or project analysis, contact our engineering team and share your design requirements.

FAQ

Q1: What testing documents are typically required for landfill projects?

Most buyers request ASTM test reports covering tensile strength, tear resistance, puncture strength, carbon black content, and permeability results.

Q2: How do composite geomembranes perform on steep landfill slopes?

The integrated geotextile layer increases friction angle, improving slope stability and reducing the risk of slippage during installation.

Q3: Can the liner design be customized for aggressive chemical environments?

Yes. Custom formulations and reinforced structures allow enhanced resistance to leachate, hydrocarbons, and industrial by-products.

Q4: What is the typical delivery time for large landfill liner orders?

Lead times vary by order volume, but international buyers commonly schedule production within 10–21 days depending on customization levels.

Authoritative Notes

Industry performance data referenced herein aligns with widely recognized geosynthetics engineering standards and global environmental protection guidelines.

Material specifications reflect accepted testing criteria from international geotechnical and polymer research bodies.