EPDM Geomembrane

Manufacturing Process

The performance reliability of EPDM Geomembrane depends on a controlled rubber processing workflow.

EPDM polymer compounding with fillers and additives

Internal mixer or open mill mixing

Sheet extrusion or calendering

Vulcanization (hot-air or continuous press system)

Surface cooling and dimensional stabilization

Thickness inspection and mechanical testing

Roll cutting, packaging, and batch labeling

Product Definition

EPDM Geomembrane is a synthetic rubber impermeable liner manufactured from ethylene propylene diene monomer, engineered for long-term waterproofing, flexibility, and weather resistance in hydraulic, environmental, and civil engineering containment systems.

Technical Parameters and Specifications

For engineering-grade applications, EPDM Geomembrane must meet stable mechanical, chemical, and environmental performance requirements.

Standard thickness: 0.8 mm / 1.0 mm / 1.2 mm / 1.5 mm

Density: 1.15–1.25 g/cm³

Tensile strength: ≥8 MPa

Elongation at break: ≥300%

Tear resistance: ≥25 kN/m

Hardness (Shore A): 60 ±5

Operating temperature range: -40°C to +120°C

UV and ozone resistance: Excellent (no cracking)

Water vapor permeability: ≤1.0 × 10⁻¹¹ g·cm/cm²·s·Pa

Structure and Material Composition

EPDM Geomembrane is a homogeneous elastomeric sheet designed for elasticity and environmental durability.

Base Polymer: EPDM synthetic rubber

Reinforcing Fillers: Carbon black for strength and UV stability

Curing System: Sulfur or peroxide-based vulcanization

Processing Oils: Flexibility enhancement

Additives: Antioxidants and anti-aging agents

Manufacturing Process

The performance reliability of EPDM Geomembrane depends on a controlled rubber processing workflow.

EPDM polymer compounding with fillers and additives

Internal mixer or open mill mixing

Sheet extrusion or calendering

Vulcanization (hot-air or continuous press system)

Surface cooling and dimensional stabilization

Thickness inspection and mechanical testing

Roll cutting, packaging, and batch labeling

Industry Comparison

| Property | EPDM Geomembrane | HDPE Geomembrane | LLDPE Geomembrane | PVC Geomembrane |

|---|---|---|---|---|

| Flexibility | Excellent | Moderate | High | High |

| UV / Ozone Resistance | Excellent | Excellent | Good | Moderate |

| Low Temperature Performance | Excellent | Moderate | Good | Moderate |

| Chemical Resistance | Moderate | Excellent | Good | Moderate |

| Service Life | 25–30 years | 30–50 years | 20–30 years | 15–20 years |

Application Scenarios

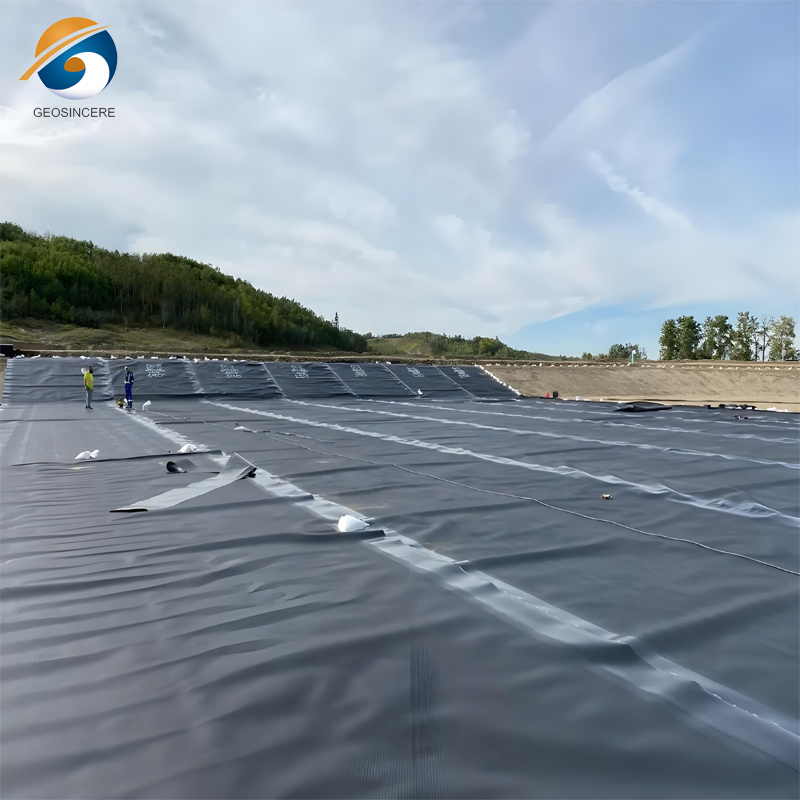

EPDM Geomembrane is selected where flexibility, weather resistance, and movement accommodation are critical.

Distributors: Pond liners and landscape water features

EPC contractors: Artificial lakes, reservoirs, and canals

Engineering firms: Roof waterproofing and foundation isolation

Infrastructure projects: Decorative water bodies and irrigation systems

Core Pain Points and Engineering Solutions

Substrate movement: EPDM elasticity absorbs settlement and deformation

Extreme temperature exposure: Stable performance from -40°C to +120°C

UV aging: Inherent ozone and UV resistance reduces surface cracking

Complex detailing: Easy field shaping for corners and penetrations

Risk Warnings and Mitigation

Improper selection or installation of EPDM Geomembrane can lead to premature system failure.

Avoid prolonged exposure to hydrocarbons and oils

Ensure compatible adhesives and seam tapes are used

Protect liner from sharp objects during installation

Verify curing quality and mechanical test reports

Procurement and Selection Guide

Confirm application environment and temperature range

Select thickness based on mechanical stress

Evaluate chemical exposure compatibility

Review manufacturing process and curing method

Request standard compliance documentation

Check roll size, packaging, and logistics feasibility

Obtain installation manuals and seam method guidance

Engineering Case Application

In a landscaped artificial lake project covering 18,000 m², a 1.2 mm EPDM Geomembrane liner was installed over a sand-cushioned subgrade. The liner accommodated seasonal thermal expansion and minor ground settlement, maintaining watertight performance after six years of continuous service.

FAQ

Q1: Is EPDM Geomembrane suitable for cold climates? A: Yes, down to -40°C.

Q2: How are seams formed? A: Using adhesive bonding or seam tape.

Q3: Can EPDM be exposed to sunlight? A: Yes, without additional cover.

Q4: Is EPDM resistant to acids? A: Moderate resistance; testing recommended.

Q5: Typical roll width? A: Commonly 3–6 meters.

Q6: Does EPDM require welding? A: No hot welding required.

Q7: What is the expected service life? A: 25–30 years.

Q8: Is EPDM suitable for potable water? A: Yes, with certified grades.

Q9: Can EPDM handle structural movement? A: Yes, due to high elasticity.

Q10: What standards apply? A: ASTM D4637, ASTM D412.

Call to Action

For EPDM Geomembrane technical datasheets, engineering samples, installation guidance, or project-specific quotations, procurement and engineering teams are encouraged to request detailed technical documentation.

E-E-A-T Author Credentials

This content is prepared by a geosynthetics and waterproofing engineering specialist with over 15 years of experience supporting EPC contractors, infrastructure developers, and international B2B procurement teams in liner system specification and application.