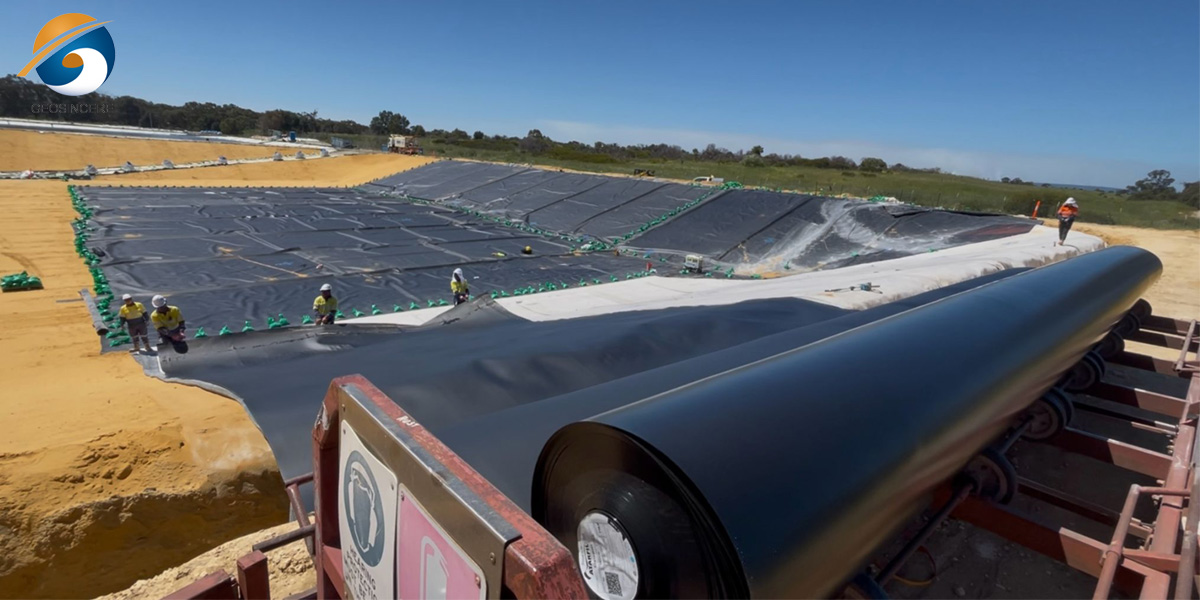

High Density Polyethylene Liner

The High Density Polyethylene Liner is a high-quality and robust geomembrane manufactured with premium HDPE resin. The product aims to deliver superior containment and waterproofing performance even in the most challenging engineering and environmental contexts.

- Outstanding chemical and corrosion resistance

- Very low permeability ensuring effective seepage control

- Excellent tensile strength and puncture resistance

- Resistant to UV radiation for prolonged outdoor applications

- Extended service time combined with low maintenance requirements

The HDPE Liner is a deluxe geomembrane product made with a focus on superior durability, flexibility, and resistance to chemicals. It comfortably fits environmental, industrial, and civil engineering use cases.

High Density Polyethylene Liner is a high-performance geomembrane widely used in civil, environmental, and industrial applications for its superior strength, durability, and chemical resistance. It is manufactured from high-quality HDPE resin, ensuring consistent thickness, flexibility, and long-term reliability.

1. High Density Polyethylene Liner – Composition & Manufacture

1.1 Virgin HDPE Resin

The use of newly harvested virgin HDPE resin in the manufacturing process is the main reason behind the product's great durability, chemical resistance, and lasting performance. Besides, the hdpe geomembrane sheet thickness and its physical properties remain consistent throughout the material.

1.2 Surface Options – Smooth or Textured

- Smooth Surface: Creates a hygienic, impermeable barrier which is perfect for water storage, chemical containment, and covering flat surfaces.

- Textured Surface: Its main focus is at increasing friction, helping the slope retain its stability, and hence reducing the risk of liner slippage in sloped or inclined applications.

1.3 Color Options

- Standard Black: Provides excellent UV resistance, thermal stability, and opacity for most industrial and environmental projects.

- Custom Colors: When the project architect requires identifying project features or taking account of the aesthetic considerations, such a need may be met through producing the custom colors.

1.4 Manufacturing Accuracy

The adoption of extrusion and calendaring at a very high technology level has allowed for the production of high tensile strength, uniform density, and proper thickness across the entire material hdpe membrane sheet. The high density polyethylene liner material thus becomes weaker at fewer points, and the product becomes the more reliable under challenging conditions that demand superior performance.

2. High Density Polyethylene Liner – Properties

2.1 Thickness:

- Scope: 0.2mm – 3.0mm (approx. 8 mil – 120 mil).

Increased thickness results in higher puncture resistance and the liner's durability suitable for heavy load applications like landfills, mining, and chemical containment.

Lower thickness hdpe geomembrane can be used for less demanding situations such as irrigation canals, ponds, and temporary containment systems.

2.2 Color Options:

- Standard Black: Provides excellent UV resistance, thermal stability, and opacity.

- Others: Blue, green, white, or dual-color (different color on each side) for specific project needs.

- Custom colors can be used to fulfill the aesthetic aspect of the project, identify the project visually, or meet the regulation limit requirements.

2.3 Surface Finish:

- Smooth Surface: Is the best choice for water retention, chemical storage, and installations on even surfaces.

- Textured Surface: Can be used on slopes, embankments, and so on, where more friction resulting from the texture and anchor will prevent slipping.

2.4 Tensile Strength:

- Minimum tensile strength: ≥20 MPa.

Makes it resistant to being torn or stretched even after repeated use or extreme treatment during the installation or operation phases.

Fit for heavy loads, environmental stress, and long-term use.

2.5 Elongation at Break:

- ≥700%, which means the liner can stretch to an extraordinary degree without breaking.

Helps to solve the issues of the ground settlement, thermal expansion, as well as the existence of minor surface irregularities.

2.6 Density:

- 0.94 – 0.96 g/cm³, which indicates that the material is strong and stable.

Is a factor in the weight being consistent, flexibility, and resistance to chemicals.

2.7 Operating Temperature:

- Range: -60°C to +80°C, capable of withstanding extremely cold or hot weather conditions.

Retains its physical form in case of very cold or scorching temperatures.

3. High Density Polyethylene Liner – Features and Benefits

3.1 Excellent Chemical Resistance:

Polymer has a high level of resistance to chemicals such as acids, alkalies, salts, and hydrocarbons. Can be used in extremely noisy industrial and mining areas where chemical exposure is frequent. Guarantees permanent stability without loss of properties if it comes into contact with aggressive liquids.

3.2 Low Permeability:

Acts as a barrier with almost zero permeability, thus effectively controlling the leakage of liquids and contaminants. Protects soil, groundwater, and the environment from pollution. The high density polyethylene pond liner is perfectly suited for use in landfill environments, waste water treatment plants, and areas of chemical storage.

3.3 High Tensile Strength:

The high density polyethylene geomembrane material can tolerate high mechanical stresses, heavy loads, and pressure without tearing or breaking effectively. The material does not lose its shape after ground settlement, hydraulic pressure, or repeated loading. The material can be used for a variety of industrial or environmental engineering projects.

3.4 Puncture and Impact Resistance:

Can take a lot of abuse from sharp objects such as rocks or rough ground during installation and operation. Controls the risk of damage during handling, transport, or when the material comes into contact with construction activities. The hdpe geomembrane liner material will work for a very long time thus no constant check-ups and cost on the maintenance are required.

3.5 UV and Weather Resistance:

The product keeps up its quality even after being exposed to sunlight for a long time and to the extremes of weather. Being resistant to oxidation, heat, and cold, it is suitable for outdoor use and, therefore, a very long life. Less damage from the environment is experienced with time.

3.6 Flexibility:

Allows for easy welding, folding, and shaping to irregular surfaces, slopes, or complicated geometries. HDPE geomembrane pond liner makes installation in difficult terrain or irregularly shaped containment areas a whole lot easier. It also helps to combine it with other geosynthetics materials to make a reinforced system.

3.7 Long Service Life:

The polyethylene geomembrane product is extremely durable and can last for about 20–30 years under normal use. This helps to reduce the cost of replacement and maintenance of the product in the long run. Besides that, high density polyethylene hdpe liners is perfect for use in short-period projects as well as in long-term environmental protection.

4. High Density Polyethylene Liner – Advantages Over Other Liners

4.1 Longer Lifespan than PVC and LDPE Liners:

HDPE liners are generally considered to be highly durable and have a long useful life ranging from 20 to 30 years under normal operating conditions.Over time, in contrast to PVC and LDPE liners, HDPE is able to retain its strength and functionality, thereby cutting down on costs for replacements and repairs.

4.2 Better Chemical and UV Resistance than Most Alternatives:

HDPE is a great choice for industrial and environmental uses because it is very resistant to chemicals, acids, alkalis, salts, and hydrocarbons. Due to its high UV resistance, the material will show very little degradation if exposed to sunlight for a long time and thus can better outdoor installation of the liner than most other materials.

4.3 Strong Yet Flexible for Versatile Installation:

High density pond liner is a good match of features in the sense of strength and elasticity that allows the plastic to be mechanically strong while, at the same time, being able to conform to irregularities in the ground, slopes and complicated shapes. High density polyethylene geomembrane also makes the material installation easier in difficult terrains and, therefore, HDPE lining can be used in many different mining pond applications, as well as irrigation canals, etc.

5. High Density Polyethylene Liner – Applications

5.1 Landfills:

Generally, hdpe geomembrane sheet is used in the lining and capping of landfill sites so that leachate doesn’t get into the soil and water.Ensures long-term environmental protection and full compliance with regulations. Municipal, industrial, and hazardous wastes can all be appropriately contained with the help of this being lined.

5.2 Mining:

Is most suitable for tailings ponds, heap leach pads, and other mining containment systems.The system supplies excellent security for the environment from the escape of slurry and waste industrial chemicals. Is chemically resistant to pollutants and can tolerate the extreme weather conditions characteristic of mining operations.

5.3 Water Management:

Serves as a liner for reservoirs, irrigation channels, ponds, and artificial lakes so that water loss through seepage is minimized.Consequently, it is able to keep water levels required for agriculture, human consumption, and recreation.The hdpe liner is environmentally friendly and supports sustainable water management practices in different climate conditions.

5.4 Industrial Containment:

Examples include chemical storage tanks, wastewater treatment plants, and secondary containment areas.Neutralizes the impact of industrial chemicals on the soil and water in the vicinity.Are resistant to chemical and mechanical damage, thus giving the containment to be trustable.

5.5 Agriculture and Aquaculture:

Usage in fish farms, agricultural ponds, and animal waste management.Depends on the water quality and reductions in leakage that might indirectly be affect crops or animals.Geomembrane sheet is also resistant to UV, chemicals, and mechanical stress, thereby giving it a long life in outdoor conditions.

6. GEOSINCERE Geosynthetics – High Density Polyethylene Liner FAQ

Q1: What makes high density polyethylene liner suitable for chemical containment?

A: HDPE liners are great resistant to a wide range of chemicals including acids, alkalis, salts, hydrocarbons, and more.

Q2: Can high density polyethylene liner withstand extreme temperatures?

A: Yes, they can comfortably operate within the temperature range of -60°C to +80°C, maintaining their characteristics in both freezing and hot conditions.

Q3: How durable is an high density polyethylene liner?

A: Our GEOSINCERE HDPE liners are made to last 20–30 years and provide excellent long-term containment with minimal maintenance, in contrast to PVC or LDPE liners.

Q4: How is an high density polyethylene liner installed?

A: HDPE liners can be fused by heat or joined by extrusion welding to make completely leak-proof seams.

Conclusion & Recommendation

Shandong Geosino New Material Co., Ltd. (GEOSINCERE Geosynthetics) High Density Polyethylene Liner delivers reliable containment, long-lasting durability, and environmental protection. It is a top pick for civil, industrial, agricultural, and environmental engineering projects due to its great performance, flexibility, and eco-friendliness.