Geocell for Slope Erosion Control In Road Construction

Manufacturing Process

HDPE Sheet Extrusion

Resin is melted at controlled temperature, extruded into uniform sheets of 1.1–1.6 mm thickness.Surface Texturing & Perforation

Embossing rollers add texture; CNC punching creates drainage holes if required.Ultrasonic Welding

Automated welding machines bond strips at precise intervals, ensuring consistent cell dimensions.Panel Expansion & Sizing

Geocell sections are expanded and measured to confirm design geometry.Quality Inspection

Tests include tensile strength, weld peel strength, thickness tolerance, and perforation accuracy.Packing & Palletizing

Panels are compressed and strapped for transportation to road construction sites.

Product Definition

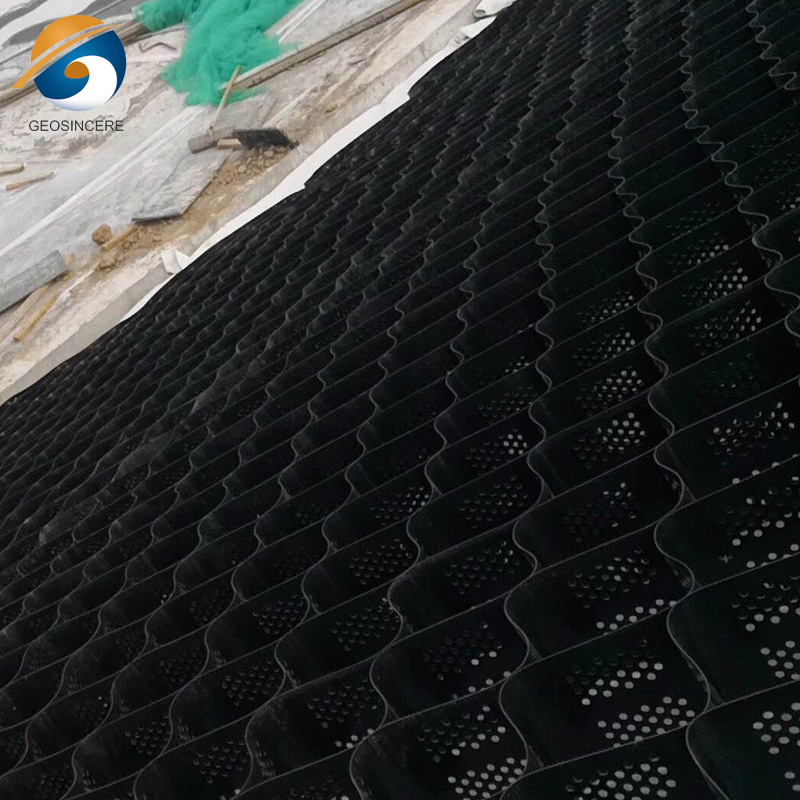

Geocell for slope erosion control in road construction is a three-dimensional HDPE honeycomb confinement system used to stabilize soil, resist slope runoff, and improve long-term structural integrity in highway and municipal earthwork projects.

Technical Parameters & Specifications

Material: High-Density Polyethylene (HDPE)

Cell Height: 75 mm / 100 mm / 150 mm / 200 mm

Cell Welding Distance: 330 mm–660 mm

Sheet Thickness: 1.1–1.6 mm (depending on load class)

Perforation Type: Non-perforated or perforated for drainage

Tensile Strength (strip): ≥12–20 kN/m

Interface Shear Strength: ≥1.0 kN

Service Life: 50 years in buried conditions

Structure & Material Composition

HDPE Strips — Base structural element providing tensile stability.

Ultrasonic Welded Joints — Connect strips into expandable cellular sections.

Optional Perforation — Enhances soil interaction and water dissipation.

Textured Surface — Improves friction with infill materials.

Manufacturing Process

HDPE Sheet Extrusion

Resin is melted at controlled temperature, extruded into uniform sheets of 1.1–1.6 mm thickness.Surface Texturing & Perforation

Embossing rollers add texture; CNC punching creates drainage holes if required.Ultrasonic Welding

Automated welding machines bond strips at precise intervals, ensuring consistent cell dimensions.Panel Expansion & Sizing

Geocell sections are expanded and measured to confirm design geometry.Quality Inspection

Tests include tensile strength, weld peel strength, thickness tolerance, and perforation accuracy.Packing & Palletizing

Panels are compressed and strapped for transportation to road construction sites.

Industry Comparison

| Material | Erosion Control | Load Support | Drainage | Cost Efficiency |

|---|---|---|---|---|

| HDPE Geocell | Excellent | High | Good | High |

| Geotextile | Moderate | Low | High | High |

| Riprap | High | High | Moderate | Low |

| Concrete Blocks | High | High | Low | Low |

Application Scenarios

Highway slope erosion control and embankment reinforcement.

Municipal road shoulders requiring vegetation stabilization.

Culvert exits and drainage slopes with high runoff velocity.

Railway subgrade protection and side-slope stabilization.

Pipeline corridors and utility access roads requiring soil confinement.

Core Pain Points & Engineering Solutions

Severe Rainfall Runoff: Geocell confinement reduces surface erosion and enhances slope stability.

Poor Soil Conditions: Improves bearing capacity by distributing loads across the cellular structure.

Vegetation Failure on Slopes: Perforated geocells retain nutrients and moisture, improving plant root anchorage.

Slope Slippage Risk: HDPE textured surfaces increase interface friction, preventing downward soil movement.

Risk Warnings & Avoidance Recommendations

Do not install during heavy rain or when soil moisture exceeds engineering limits.

Avoid using infill with oversized stones that can deform geocell walls.

Check weld strength regularly to prevent panel tearing on steep slopes.

Ensure anchoring trenches are constructed according to design depth.

Procurement Selection Guide

Confirm slope angle, soil conditions, and anticipated load requirements.

Select appropriate cell height (100–150 mm for general slopes; 200 mm for high-load areas).

Determine perforation type based on drainage needs.

Evaluate welding strength and cell geometry consistency.

Request material test results: tensile strength, weld peel strength, and thickness reports.

Assess supplier capability for bulk delivery and installation guidance.

Engineering Case: Highway Slope Stabilization

In a regional highway expansion project with slopes up to 1:1.5, engineers applied 150 mm perforated HDPE geocell filled with granular soil. Anchoring trenches were installed at the crest, and panels were secured using steel stakes. Vegetation was added after compaction. Monitoring over 24 months showed a 90% reduction in surface erosion, with no observed slope deformation under seasonal rainfall loads.

FAQ

What determines geocell performance? Cell height, strip thickness, welding strength, and infill quality.

What cell height is recommended? 100–150 mm for typical road slopes.

Does perforation affect durability? No; it improves drainage while maintaining structural integrity.

Can geocell be used with vegetation? Yes; perforations support root penetration and moisture retention.

Is geocell suitable for high-traffic road shoulders? Yes, with proper compaction and 1.5 mm strip thickness.

What anchoring method is recommended? Rebar stakes and crest anchor trenches.

How long does HDPE geocell last? Over 50 years in buried conditions.

Can geocell replace riprap? In many cases, yes, with lower cost and easier installation.

What infill materials can be used? Soil, sand, crushed aggregate, or vegetation mix.

How to verify quality? Inspect weld spacing, thickness uniformity, and tensile property reports.

Request Quotation / Technical Files / Samples

For project-specific recommendations, quotations, detailed geocell specifications, or engineering samples, please contact our technical support team.

E-E-A-T Author Credentials

This article is prepared by a geosynthetics engineering specialist with over 10 years of experience in slope protection design, HDPE geocell manufacturing, and road construction consulting, involving EPC projects across highway, railway, and municipal sectors.