1500 Micron Black Durable Geomembrane Sewage Treatment

The demand for 1500 micron black durable geomembrane sewage treatment materials has increased significantly as global wastewater infrastructure expands. With rising urbanization and stricter environmental regulations, countries across Asia, the Middle East, Africa, and Latin America are accelerating investments in sewage treatment plants, industrial effluent control systems, and municipal wastewater upgrades.

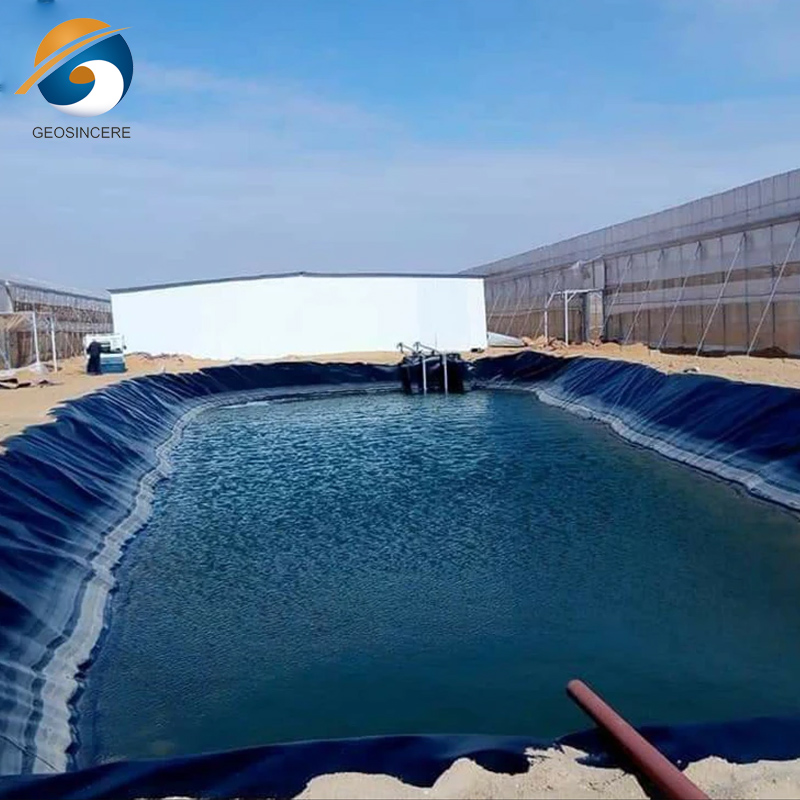

Sewage treatment facilities depend on impermeable liners to prevent leakage, control seepage, and protect soil and groundwater. High-thickness geomembranes, especially those at 1500 microns, are considered one of the most reliable solutions due to their enhanced chemical resistance, UV stability, and long service life.

Global Demand for 1500 Micron Black Durable Geomembrane in Sewage Treatment

The demand for 1500 micron black durable geomembrane sewage treatment materials has increased significantly as global wastewater infrastructure expands. With rising urbanization and stricter environmental regulations, countries across Asia, the Middle East, Africa, and Latin America are accelerating investments in sewage treatment plants, industrial effluent control systems, and municipal wastewater upgrades.

Sewage treatment facilities depend on impermeable liners to prevent leakage, control seepage, and protect soil and groundwater. High-thickness geomembranes, especially those at 1500 microns, are considered one of the most reliable solutions due to their enhanced chemical resistance, UV stability, and long service life.

Market Trends and Industry Insights

According to recent sector analyses, the global geomembrane market continues to grow at a steady pace driven by environmental compliance requirements and infrastructure development. Heavy-duty liners are particularly in demand for sewage treatment, sludge storage, evaporation ponds, anaerobic lagoons, and industrial waste containment.

A growing trend is the shift toward thicker and more durable materials, with 1500-micron black geomembranes ranking among the most preferred options for high-risk wastewater applications. International buyers increasingly prioritize materials that meet ISO, ASTM, and environmental engineering standards.

Long-tail related keywords naturally aligned with this trend include “HDPE geomembrane for wastewater projects”, “chemical-resistant geomembrane liner”, “industrial sewage pond liner”, and “reinforced geomembrane for treatment plants”.

Technical Parameters of 1500 Micron Black Durable Geomembrane

A 1500-micron geomembrane corresponds to approximately 1.5 mm thickness, offering enhanced mechanical strength and impermeability.

Typical technical characteristics include:

• High tensile strength suitable for dynamic loading in large wastewater basins

• Excellent puncture and tear resistance to withstand rough subgrade conditions

• Superior chemical resistance to acids, alkalis, sludge liquids, and industrial effluents

• Very low permeability to ensure long-term seepage control

• UV stabilization for extended outdoor exposure

• High environmental stress cracking resistance for long design life

These properties make the 1500 micron black durable geomembrane sewage treatment solution reliable for both municipal and industrial applications requiring long-term environmental protection.

Product Structure and Material Composition

The geomembrane is typically manufactured from premium HDPE resin blended with carbon black, antioxidants, and stabilizers.

Core structural advantages include:

• Uniform 1500-micron thickness for consistent performance

• Carbon black content around 2–3% for optimal UV protection

• Smooth or textured surface options depending on slope stability requirements

• Homogeneous polymer matrix ensuring durability and chemical resistance

• Reinforced molecular structure designed for long-term wastewater contact

This composition ensures that the liner maintains stability even under aggressive wastewater conditions.

Manufacturing and Quality Control Process

Production of heavy-duty geomembranes follows a precise blown-film or flat-die extrusion process.

Manufacturing steps include:

• Resin selection aligned with international safety and mechanical performance standards

• Controlled extrusion to achieve accurate 1500-micron thickness

• Cooling and stabilization to ensure dimensional stability

• Surface finishing (smooth or textured) depending on project design

• Roll winding and inspection to detect pinholes, uneven surfaces, or weak bonding

• Laboratory testing for tensile strength, puncture resistance, chemical resistance, and permeability

Every batch undergoes rigorous QA protocols to ensure long-term reliability in sewage treatment applications.

Application Scenarios in Sewage Treatment Systems

The 1500 micron black durable geomembrane sewage treatment liner is widely used in:

• Sewage treatment plant basins

• Sludge dewatering fields

• Industrial wastewater collection ponds

• Leachate containment systems

• Evaporation ponds and anaerobic lagoons

• Chemical processing wastewater units

Its impermeability prevents contamination of surrounding soil and groundwater, while its chemical resistance ensures stability even in high-pollution environments.

International Buyer Preferences and Key Purchasing Pain Points

Global procurement managers typically focus on technical performance, durability, certification, and cost efficiency.

Key buyer expectations include:

• Verified material testing reports (ASTM/ISO)

• Consistent thickness (strict 1500-micron accuracy)

• Strong welding performance and compatibility with hot wedge and extrusion welding

• Reliable delivery time and stable product quality

• Clear technical data sheets and installation guidance

Common pain points include inconsistent thickness, low-quality raw materials, poor welding properties, and insufficient factory documentation. Providing complete technical support, installation guidance, and long-term supply capability significantly increases trust and conversion in the B2B procurement process.

Conclusion and Professional Call-to-Action

The 1500 micron black durable geomembrane sewage treatment liner plays a critical role in modern wastewater management. Its mechanical durability, chemical resistance, and environmental safety make it an essential material for sewage treatment projects worldwide.

We support global engineering companies, EPC contractors, and municipal authorities with professional geomembrane solutions tailored to their project requirements.

To obtain detailed technical specifications, project case studies, or material samples, international buyers are encouraged to request a customized quotation or technical consultation.

FAQ

Q1: Is 1500-micron geomembrane suitable for high-pollutant industrial wastewater?

Yes. Its enhanced chemical resistance and mechanical strength make it ideal for aggressive wastewater conditions.

Q2: What installation method is recommended?

Hot-wedge welding and extrusion welding are commonly used to ensure strong, leak-proof seams.

Q3: How long is the expected service life?

With proper installation, the lifespan can exceed 20–30 years depending on exposure and chemical concentration.

Q4: Can buyers request customized roll sizes?

Yes, roll length, width, and surface type can be customized based on project requirements.

For detailed pricing, engineering support, and sample evaluation, please contact our technical team to start your project consultation.