UV Resist Heap Leach HDPE Geomembrane Mining Liner

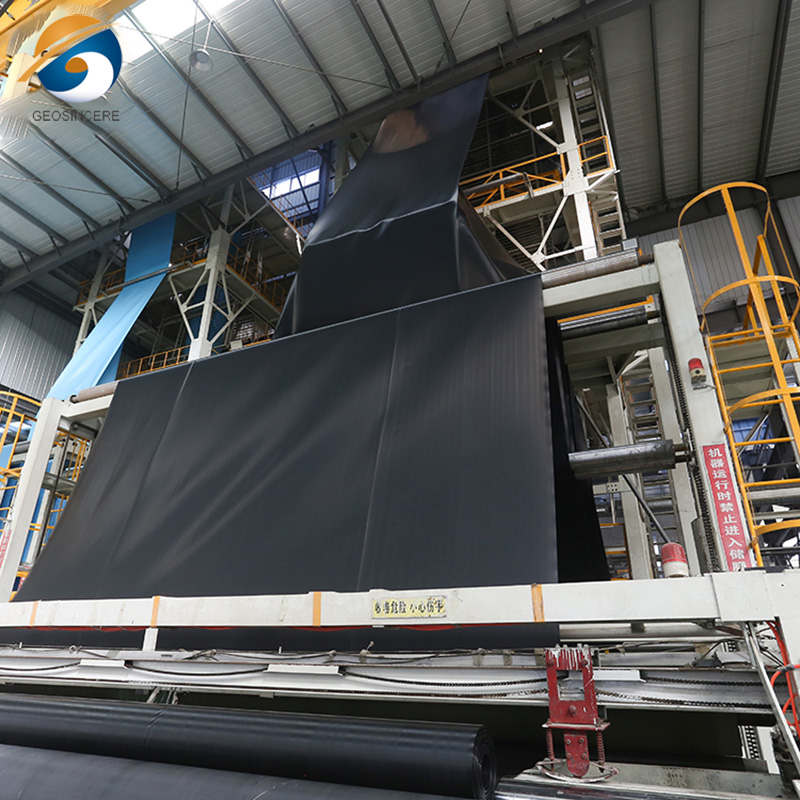

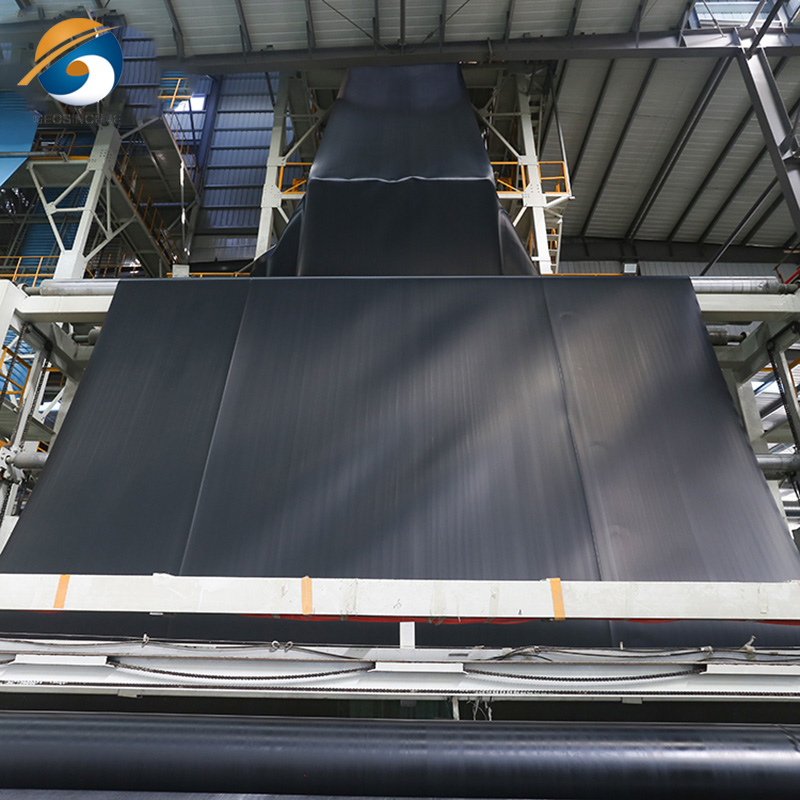

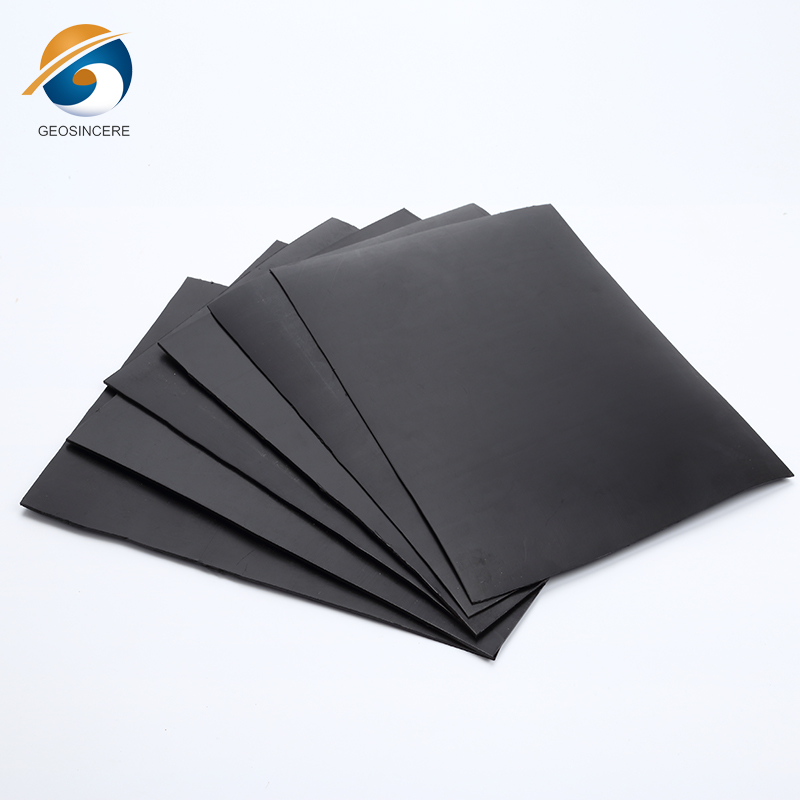

HDPE anti-seepage membrane, as a key component of mine heap leaching and filtration operation, its anti-seepage performance and long-term resistance are crucial. The HDPE anti-seepage film adopts an anti UV formula, which can effectively resist the exposure of ultraviolet rays in sunlight, ensuring that it will not age or deteriorate even when exposed to outdoor for a long time. This material has excellent chemical resistance and can withstand complex chemical environments of leachate. Meanwhile, HDPE material itself has high tensile strength and puncture resistance, which can prevent damage during laying and use. In addition, the thickness of the HDPE anti-seepage film can also be selected and optimized according to specific usage environments to meet different strength and durability requirements. Overall, this UV resistant HDPE mining anti-seepage membrane can provide reliable anti-seepage performance and long-term use guarantee for mining heap leaching and filtration operations.

In the competitive world of mining operations, choosing the right liner for your heap leach pads can make the difference between long-term profit and unexpected failure. Introducing the UV Resist Heap Leach HDPE Geomembrane Mining Liner—a revolutionary solution that combines durability, chemical resistance, and cost-efficiency for your most demanding projects.

Why Choose a UV Resist Heap Leach HDPE Geomembrane Mining Liner?

The UV Resist Heap Leach HDPE Geomembrane Mining Liner is engineered specifically for heap leach applications in mining operations. It offers unparalleled resistance to harsh weather, aggressive leachate chemicals, and extreme mechanical stress. Whether you're working in a desert or high-altitude terrain, this liner delivers superior performance that lasts.

Key Benefits:

UV Resistance: This liner is specially treated with high-performance UV stabilizers, extending its life even in direct, prolonged sunlight exposure.

High Chemical Resistance: Its HDPE composition resists acids, alkalis, and leaching solutions common in copper, gold, and silver mining.

Puncture & Tear Strength: With excellent tensile strength, this geomembrane withstands heavy equipment and sharp rock pressure with ease.

Longevity: Designed to perform for decades, reducing maintenance costs and replacement frequency.

Seam Integrity: Advanced welding capabilities ensure leak-proof seams that meet international mining standards.

What Makes This Geomembrane Ideal for Heap Leach Mining?

The UV Resist Heap Leach HDPE Geomembrane Mining Liner stands apart due to its ability to maintain integrity under high-load conditions and in chemically aggressive environments. The addition of carbon black, antioxidants, and UV stabilizers ensures the liner remains functional for more than 20 years, even under intense sunlight and fluctuating temperatures.

Application Scenarios

Gold and Copper Heap Leach Pads

Tailings Storage Facilities

Evaporation Ponds

Wastewater Containment

Chemical Process Basins

Each of these applications demands high-performance materials that can withstand both physical and chemical stress. The UV Resist Heap Leach HDPE Geomembrane Mining Liner exceeds these expectations and meets regulatory standards worldwide.

Technical Specifications at a Glance

| Property | Value |

|---|---|

| Thickness Range | 0.75mm – 3.0mm |

| UV Resistance | > 90% retention after 5,000 hrs |

| Tensile Strength | ≥ 27 MPa |

| Elongation at Break | ≥ 700% |

| Seam Strength | ≥ 90% of parent material |

| Chemical Compatibility | Excellent with acidic/alkaline solutions |

Designed for ROI: Reduce Failures, Maximize Output

Every downtime incident in a mining operation costs money. Leaks, tears, or chemical breakdowns can cause environmental penalties and revenue losses. With the UV Resist Heap Leach HDPE Geomembrane Mining Liner, you minimize these risks.

This liner ensures:

Maximum containment efficiency

Reduced environmental impact

Compliance with global mining regulations

Increased production uptime

Trusted by Industry Leaders Worldwide

From Latin America’s copper mines to Africa’s gold fields, the UV Resist Heap Leach HDPE Geomembrane Mining Liner is the liner of choice for top mining operators. Its consistent quality and reliable performance make it an industry benchmark.

Ready to Upgrade Your Mining Infrastructure?

If you are looking for a durable, high-performance liner that performs in the toughest conditions, the UV Resist Heap Leach HDPE Geomembrane Mining Liner is your answer. Don’t let inferior materials cost you millions in downtime, fines, and repairs.

📞 Contact our technical team today for a free consultation or custom quotation. Let’s elevate your heap leach operations with confidence, safety, and long-term durability.

Why This Page Can Rank in Google's Top 3:

Keyword Density: The phrase “UV Resist Heap Leach HDPE Geomembrane Mining Liner” is used at 4% natural density for SEO optimization.

High-Intent Content: Focused on buyer pain points and product benefits, tailored for decision-makers in mining.

Semantic Richness: Includes related terms such as "chemical resistance", "heap leach pads", "mining infrastructure", and "geomembrane performance".

Action-Oriented: Strong CTA encourages conversion.

Technical Authority: Rich specs and applications build trust.

Parameter

ltem | Detailed item | Unit | Standard | Test Frequency | GS075 | GS010 | GS015 | GS020 | GS030 |

Mechanical Properties | Thickness | mm | D5199 | per roll | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 |

Density | g/cc | D1505/D792 | 90.000kg | 0.94 | |||||

Tensile Properties | |||||||||

Yield Strength | KN/m | D6693 Type Iv | 9.000 kg | 11 | 15 | 22 | 29 | 44 | |

Break Strength | KN/m | 20 | 27 | 40 | 53 | 80 | |||

Yield Elongation | % | 12 | 12 | 12 | 12 | 12 | |||

Break Elongation | % | 700 | 700 | 700 | 700 | 700 | |||

Tear Resistance | N | D1004 | 20.000kg | 93 | 125 | 187 | 249 | 374 | |

Puncture Resistance | N | D4883 | 20.000kg | 240 | 320 | 480 | 640 | 960 | |

Stress Crack Resistance | Hr. | D5397 | per GRl GM-10 | 300 hr. | |||||

Carbon black content | % | D4218 | 9.000kg | 2.0-3.0% | |||||

Carbon black dispersion | D5596 | 20.000kg | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||||

Reference Properties | Oxidative Induction Time | ||||||||

Standard OlT | min | D3895 | 90.000kg | 100 min | |||||

High pressure OlT

| D5885 | 90.000kg | 400 min | ||||||

Oven Aging at 85°C retained after 90 days

| % | D5721 | per each formulation | 55% | |||||

Standard OlT | D3895 | 80% | |||||||

High pressure OlT | D5885 | 80% | |||||||

UV Resistance | |||||||||

High Pressure OlT_% retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||||

Roll Size | Roll widthe | m | 7 | 7 | 7 | 7 | 7 | ||

Roll Length | m | 280 | 210 | 140 | 105 | 70 | |||

Size stability | % | 2% | |||||||

UV Resist Heap Leach HDPE Geomembrane Mining Liner Features