2mm HDPE Geomembrane Liner for Biogas Digester

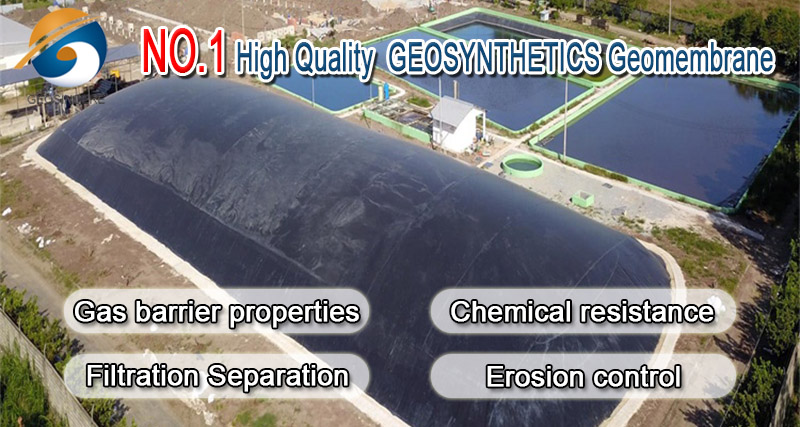

As global demand for renewable energy accelerates, biogas projects have become a critical component of agricultural modernization, industrial waste treatment and circular energy development. The 2mm HDPE geomembrane liner for biogas digester is widely adopted as a primary sealing and containment material due to its durability, impermeability and chemical resistance. In recent years, governments in Asia, Africa, Europe and Latin America have expanded subsidies and policy support for biogas infrastructure, significantly driving procurement demands for geomembrane liners used in biogas pond liner systems and digester sealing applications.

According to recent industrial data, the global geomembrane market has surpassed USD 3.5 billion, with HDPE materials dominating more than 45% of the total share. Biogas plant construction remains one of the fastest-growing application sectors, especially for large-scale anaerobic digesters used by livestock farms, food processing companies and municipal waste treatment facilities. As energy security becomes a strategic priority, high-performance HDPE lining systems are expected to maintain steady compound annual growth.

Global Market Background of 2mm HDPE Geomembrane Liner for Biogas Digester

As global demand for renewable energy accelerates, biogas projects have become a critical component of agricultural modernization, industrial waste treatment and circular energy development. The 2mm HDPE geomembrane liner for biogas digester is widely adopted as a primary sealing and containment material due to its durability, impermeability and chemical resistance. In recent years, governments in Asia, Africa, Europe and Latin America have expanded subsidies and policy support for biogas infrastructure, significantly driving procurement demands for geomembrane liners used in biogas pond liner systems and digester sealing applications.

According to recent industrial data, the global geomembrane market has surpassed USD 3.5 billion, with HDPE materials dominating more than 45% of the total share. Biogas plant construction remains one of the fastest-growing application sectors, especially for large-scale anaerobic digesters used by livestock farms, food processing companies and municipal waste treatment facilities. As energy security becomes a strategic priority, high-performance HDPE lining systems are expected to maintain steady compound annual growth.

Market Trends and Procurement Drivers

The increasing preference for renewable energy projects is accompanied by a rise in strict environmental compliance standards. International buyers now require geomembrane liners that meet ISO, CE and various regional testing certifications. The 2mm HDPE geomembrane liner for biogas digester is particularly favored in medium to large anaerobic digestion systems because it provides mechanical strength, long-term UV resistance and a stable barrier against methane leakage.

Another significant trend is the growing adoption of automated welding technologies for geomembrane installation. This enhances bonding quality and reduces the probability of seam failure, which is critical in biogas membrane cover systems where gas pressure stability must be maintained. Buyers increasingly request manufacturers who offer both liner materials and technical support for on-site installation.

Technical Specifications of 2mm HDPE Geomembrane Liner

The 2mm HDPE geomembrane liner for biogas digester is engineered to withstand complex chemical and mechanical stress conditions. Standard technical parameters typically include:

• Thickness: 2.0mm nominal

• Tensile Strength: ≥ 27 MPa

• Tear Resistance: High-rate tear propagation resistance

• Puncture Resistance: Suitable for biogas pond liner foundations with gravel or uneven soil

• Permeability Coefficient: ≤ 1.0 × 10⁻¹⁴ g·cm/(cm²·s·Pa)

• Service Life: 20–30 years under standard exposure conditions

• Chemical Resistance: Effective against ammonia, organic acids and agricultural effluents

These parameters ensure that the material can maintain long-term sealing performance while preventing leakage, gas loss or groundwater contamination.

Product Structure and Material Composition

The liner is typically composed of high-density polyethylene resin combined with carbon black, antioxidants and anti-aging agents. The material is produced through black masterbatch compounding, followed by a blown-film or extrusion-calendering process. The final structure forms a dense, uniform layer with stable molecular alignment, giving the liner exceptional impermeability and environmental stress-cracking resistance.

Manufacturing Process Flow

1. Raw Material Selection

High-purity polyethylene granules are chosen for consistent chemical properties.

2. Extrusion and Film Forming

The resin is melted and extruded through specialized molds to achieve precise thickness control.

3. Cooling and Stabilization

The sheet is cooled by controlled air or water methods to maintain uniform mechanical properties.

4. Edge Trimming and Quality Inspection

Thickness, surface uniformity and mechanical strength are tested before packaging.

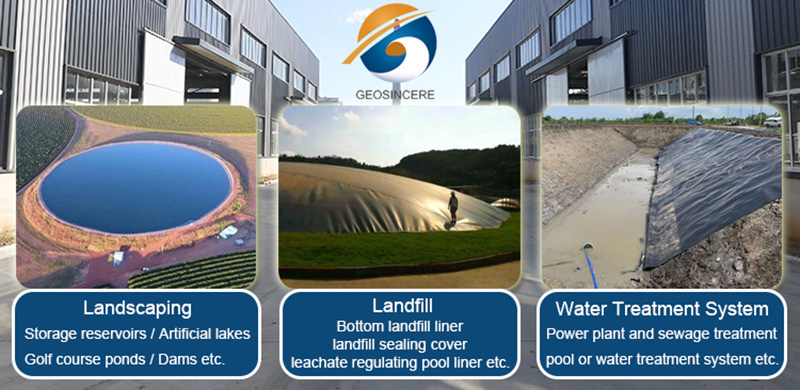

Application Process in Biogas Projects

In biogas plant construction, the 2mm HDPE geomembrane liner for biogas digester is used as the primary sealing layer for anaerobic ponds, fermentation tanks and biogas storage structures. The installation process includes site preparation, subgrade leveling, liner deployment, seam welding and vacuum testing. Proper installation ensures gas retention efficiency and prevents leakage that could compromise energy yield or environmental safety.

International Buyer Preferences and Pain Points

Buyers from emerging markets such as Southeast Asia, Africa and Latin America typically prioritize cost-effective materials with strong tensile performance for large-scale projects. Meanwhile, buyers from Europe and North America place greater emphasis on certifications, traceability and long-term environmental compliance. Across all regions, the main procurement pain points include inconsistent quality, insufficient technical support, and difficulty in determining material authenticity.

Buyers also increasingly request complete HDPE lining system solutions rather than standalone materials. This includes accessories such as geotextiles, anchor trench designs, gas-collection components and technical documents for digester sealing material applications.

Conclusion and Procurement Guidance

The 2mm HDPE geomembrane liner for biogas digester plays a foundational role in the safe and efficient operation of modern biogas systems. With the global biogas industry continuing to expand under sustainability policies, demand for high-performance liners will remain strong. Buyers seeking stable supply, technical reliability and international compliance should evaluate manufacturers based on material formulation, production capabilities, certification coverage and installation expertise.

To receive detailed quotations, technical datasheets or material samples, buyers may directly request full specifications and project-based recommendations from our engineering team.

Frequently Asked Questions (FAQ)

1. What is the ideal thickness for biogas digester lining?

The 2mm HDPE geomembrane liner is preferred for large-scale digesters because it offers superior tensile strength and long-term sealing performance.

2. Can the liner resist chemicals produced during anaerobic digestion?

Yes. HDPE liners offer strong resistance against organic acids, methane, ammonia and related by-products.

3. How long does a 2mm HDPE liner typically last?

With proper installation and UV protection, service life ranges between 20–30 years.

4. Do buyers receive technical support during installation?

We provide welding guidance, installation manuals and project recommendations to ensure optimal performance.