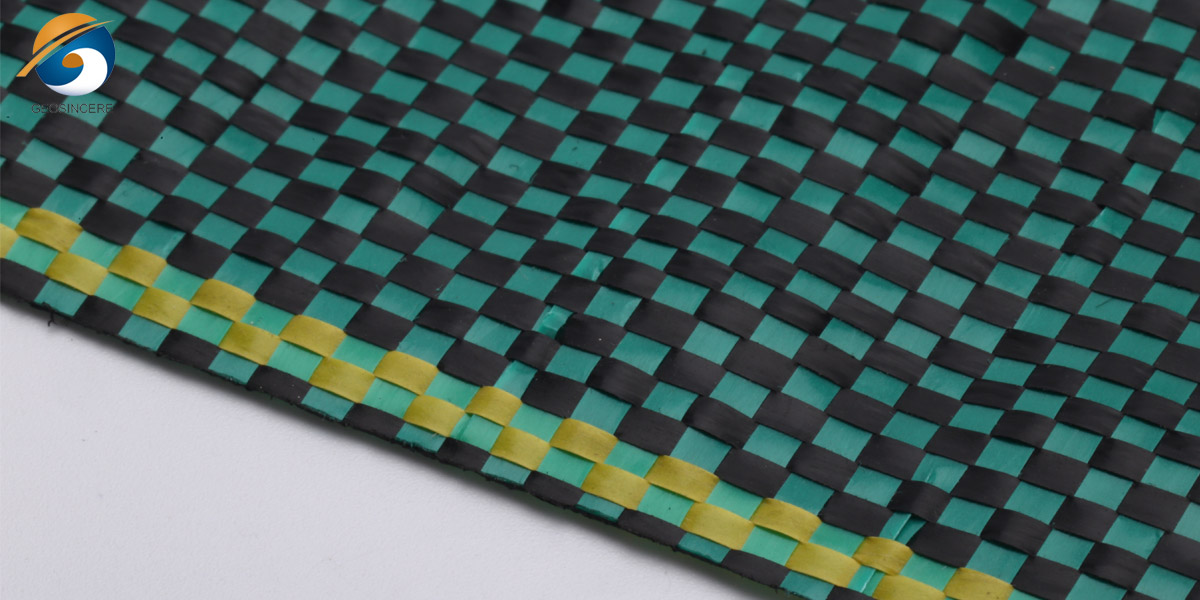

Polypropylene Woven Geotextile

Polypropylene Woven Geotextile is a high-strength, long lasting material made from UV-stabilized polypropylene tapes. It is designed for soil separation, reinforcement, filtration, and stabilization in civil engineering and environmental projects. With magnificent tensile electricity and chemical resistance, it ensures long-lasting floor overall performance underneath harsh conditions.

- High Strength & Stability: Provides finest load distribution and soil reinforcement.

- Excellent Chemical Resistance: Performs nicely in acidic, alkaline, and saline environments.

- Low Water Absorption: Maintains steadiness and overall performance even in moist conditions.

- UV & Weather Resistant: Ensures sturdiness in outside and long-term applications.

- Easy Installation: Lightweight rolls for speedy and environment friendly managing on-site.

- Applications: Road base reinforcement, embankment stabilization, erosion control, drainage systems, and maintaining wall construction.

Polypropylene Woven Geotextile is a high-performance geosynthetic fabric manufactured from slit-film or multifilament polypropylene (PP) yarns woven collectively to structure a strong, dimensionally secure fabric. Known for its extraordinary tensile strength, low elongation, and gorgeous durability, it is broadly used in civil engineering, street construction, erosion control, and drainage applications. The woven shape presents excessive load-bearing ability whilst permitting managed water flow, making it an perfect desire for soil separation, reinforcement, and filtration.

1. Polypropylene Woven Geotextile — Material Composition

1.1 Base Polymer — 100% virgin polypropylene

Made from high-grade, virgin polypropylene (PP) resin as a substitute than recycled fabric to make sure steady mechanical homes and long-term durability. Virgin PP gives uniform molecular weight distribution, predictable creep behaviour, and highest quality resistance to hydrolysis and organic attack. Using virgin polymer reduces batch-to-batch variability, improves weldability with adjoining geosynthetics, and ensures compliance with tensile, elongation and long-term power specs required in civil engineering projects. Typical advantages encompass low moisture uptake, dimensional steadiness at expanded temperatures, and recyclability at end-of-life.

1.2 Structure — Woven from slit-film or multifilament PP yarns

The geotextile fabric material is produced with the aid of weaving both slit-film tapes (extruded flat ribbons) or multifilament yarns (bundled first-class filaments). Slit-film tapes provide greater stiffness, decrease elongation and great in-plane strength, making them perfect for reinforcement and separation underneath heavy loads. Multifilament weaves furnish higher conformability and barely greater elongation, which can be high quality the place some deformation tolerance is needed. The weaving technique (plain, twill, or leno weave variants) and weave density decide aperture size, permeability, tensile electricity (machine and go directions), and elongation characteristics. Controlled weave anxiety and heat-setting in the course of manufacture make certain dimensional stability, uniform pore distribution, and predictable creep overall performance over the product’s carrier life.

1.3 Additives — UV stabilizers, anti-aging sellers for prolonged out of doors carrier life

Additives are blended into the PP soften or utilized as floor redress to defend the polymer in opposition to environmental degradation. Common components consist of carbon black and UV absorbers which block ultraviolet radiation and stop polymer chain scission; antioxidants and thermal stabilizers which retard oxidation at some point of processing and long-term ageing; and anti-hydrolysis or slip sellers the place needed. The dosage and kind of components are chosen to reap goal UV resistance (e.g., specific p.c energy retention after accelerated UV exposure), thermal steadiness for the duration of installation, and long-term retention of mechanical residences in buried or uncovered conditions. Proper additive programs limit loss of tensile strength, stop embrittlement, and prolong the layout lifestyles of out of doors installations.

1.4 Color — Commonly black, grey, or custom-made per mission needs

Black (with carbon black) is the most frequent coloration due to the fact carbon black is an nice UV stabilizer and affords finest light-blocking protection; it additionally provides a impartial aesthetic and market standard. Grey or different colours may additionally be used when visible contrast, identification, or aesthetic integration is required (e.g., landscaping, seen slope faces). Custom shades are possible thru pigmenting however may additionally require extra UV stabilizer content material to suit black’s durability. Color decision ought to account for venture necessities (visibility, warmth absorption, compatibility with adjoining materials) and any specs calling out coloration coding for extraordinary fabric grades or layers.

1.5 Surface Texture — Smooth, association texture with uniform aperture for constant performance

Surface end and aperture uniformity are managed all through weaving and heat-setting. A smooth, company floor reduces snagging in the course of installation, helps constant contact with soils and aggregates, and simplifies welding or sealing when used alongside geomembranes. Uniform aperture measurement and distribution make sure predictable hydraulic behaviour — filtration and in-plane permeability — stopping untimely clogging and making sure that pore dimension distribution fits the goal soil gradation (i.e., prevents soil particle migration whilst allowing sufficient drainage). Surface texture additionally influences interfacial friction with soils; a barely coarse face can amplify shear resistance in reinforcement applications, whilst a smoother face advantages separation and ease of placement.

2. Polypropylene Woven Geotextile Key Technical Features & Advantages

2.1 High Tensile Strength

The woven shape offers wonderful tensile electricity in each desktop and pass directions, making sure dependable load switch and reinforcement of susceptible subgrades. This property approves the fabric geotextile material to evenly distribute utilized loads, stopping rutting and agreement in roads, embankments, and foundations. The end result is more suitable soil balance and longer carrier lifestyles of the structure.

2.2 Low Elongation

Polypropylene geotextile membrane showcase minimal elongation below tension, keeping structure and performance even underneath non-stop or heavy loads. This low pressure attribute reduces deformation of the soil structure, keeping alignment and geometry of the strengthened layer. It ensures predictable and regular overall performance at some stage in the project’s sketch life.

2.3 Superior Chemical Resistance

The polypropylene polymer composition makes the woven geotextile fabric inherently resistant to acids, alkalis, salts, and most natural materials observed in soils. It stays unaffected via microbial or fungal growth, preserving mechanical integrity even in aggressive chemical environments. This makes it perfect for industrial, mining, or coastal purposes the place chemical publicity is common.

2.4 UV & Weather Resistance

UV-stabilized components are included at some point of manufacturing to shield the fibers from daylight degradation and oxidation. This ensures long-term sturdiness when the geo fabric is used in uncovered or semi-exposed environments such as slopes, embankments, and erosion manage systems. The woven landscape fabric retains tensile houses and shade steadiness even after extended out of doors exposure.

2.5 Dimensional Stability

The precision weaving system ensures uniform pore dimension distribution and regular mechanical power throughout the whole geotextile drainage fabric. This dimensional steadiness ensures dependable filtration and reinforcement overall performance barring stretching or distortion for the duration of installation. The woven geotextile material continues its designed geometry beneath mechanical and environmental stress.

2.6 Low Water Absorption

Polypropylene has a naturally hydrophobic nature, which skill the material absorbs nearly no water. This prevents swelling, weakening, or loss of power even when continuously in contact with moisture. The geotextile filter fabric keeps its mechanical overall performance and helps environment friendly drainage in moist or submerged applications.

2.7 Eco-Friendly Performance

Produced from a hundred percent recyclable polypropylene, the cloth is non-toxic, inert, and protected for groundwater and surrounding ecosystems. It does no longer leach detrimental chemical compounds or degrade into micro-pollutants, aligning with sustainable development practices. Its long provider lifestyles additionally reduces cloth consumption and protection costs.

2.8 Customizable Design

Polypropylene film geotextile can be tailor-made to meet particular challenge requirements, with on hand weights from eighty to four hundred g/m², widths from 1 to 6 meters, and variable roll lengths. Custom power ratings, aperture sizes, and coloration selections can additionally be supplied to swimsuit engineering designs. This flexibility ensures most advantageous overall performance for various purposes such as avenue bases, maintaining walls, and drainage systems.

3. Polypropylene Woven Geotextile Functional Roles

3.1 Separation

Polypropylene geo cloth acts as an high-quality separator between varied soil layers, such as granular base substances and nice subgrade soils. By stopping the intermixing of these layers, it continues the layout thickness, integrity, and overall performance of street foundations and pavements. This separation characteristic reduces combination loss, minimizes rutting, and extends the provider existence of transportation and basis systems.

3.2 Reinforcement

With its excessive tensile electricity and low elongation, the cloth offers soil reinforcement in functions involving vulnerable or compressible ground. It distributes masses evenly and reduces differential contract through forming a steady composite shape with the soil. This reinforcement impact appreciably enhances the bearing capability and steadiness of embankments, keeping walls, and different geotechnical buildings constructed over tender foundations.

3.3 Filtration

The woven shape is engineered with managed pore sizes that permit the free passage of water whilst conserving soil particles. This twin feature keeps herbal drainage whilst stopping excellent particles from migrating via the fabric, fending off clogging or erosion of subsoil. The secure filtration potential ensures long-term hydraulic overall performance in drainage, riverbank, and maintaining wall applications.

3.4 Drainage

The geo textile material promotes the in-plane go with the flow of water, functioning as a drainage medium to channel moisture away from buildings and soil layers. It helps relieve hydrostatic stress at the back of conserving walls, below pavements, and in embankments. By permitting lateral water flow, it keeps dry and steady soil conditions, enhancing structural security and longevity.

3.5 Erosion Control

When set up on slopes, riverbanks, shorelines, or embankments, the Polypropylene geotextile drainage protects soil from the erosive forces of wind, rain, and flowing water. It anchors and stabilizes the soil floor whilst permitting vegetation growth, developing a long-term, environmentally pleasant erosion manipulate system. The geotextile filter cloth fabric’s excessive power and sturdiness assist hold slope integrity and forestall sediment displacement in hydraulic and coastal projects.

4. Polypropylene Woven Geotextile Typical Applications

4.1 Road & Highway Construction

Polypropylene geo fabric cloth is broadly used for base and subgrade stabilization in avenue and dual carriageway construction. It separates aggregates from excellent subgrade soils, stopping infection and keeping the electricity and thickness of the street base. The geo fabric material’s reinforcement feature distributes site visitors hundreds evenly, reduces rutting, and will increase pavement durability, ensuing in longer provider lifestyles and decrease preservation costs.

4.2 Railway & Airport Projects

In railway tracks and airport runways, the woven geotextile affords extraordinary basis reinforcement and subgrade separation. It helps stop differential contract and deformation brought about by using heavy dynamic hundreds from trains and aircraft. The geotextile fabric near me’s excessive tensile power and low elongation enhance load distribution and decorate structural performance, ensuring secure and protected operation below repeated loading cycles.

4.3 Slope Protection & Embankments

Used as a stabilizing layer in slope and embankment construction, the geotextile fabric under gravel reinforces the soil mass and prevents sliding or erosion. It enhances slope steadiness by using growing shear resistance and retaining soil shape below rainfall or hydraulic stress. The material can additionally serve as a guide for vegetation growth, combining mechanical balance with herbal erosion manipulate benefits.

4.4 Retaining Walls

Installed in the back of conserving partitions and different gravity structures, the geotextile landscape fabric acts as each a reinforcement and a filtration layer. It strengthens the backfill soil, distributes masses evenly, and prevents soil particles from washing out whilst permitting water to drain freely. This reduces hydrostatic pressure, improves wall stability, and extends the lifespan of the holding structure.

4.5 Drainage & Filtration Systems

The woven geotextile membrane’s controlled permeability and soil retention residences make it best for subsurface drainage and filtration systems. It is used in purposes such as landfills, sports activities fields, irrigation channels, and underdrain structures to manage sediment migration and keep consistent water flow. Its long-term clogging resistance ensures dependable drainage overall performance beneath steady hydraulic pressure.

4.6 Coastal & River Engineering

In hydraulic projects, Polypropylene geotextile road fabric serves as a defensive underlayment underneath riprap, gabions, or concrete armor units. It prevents soil loss due to wave action, currents, and tidal forces whilst retaining the steadiness of the shoreline or riverbank. The material’s sturdiness and resistance to abrasion and UV publicity make it appropriate for long-term use in marine and coastal environments.

4.7 Landfill & Environmental Projects

When used in aggregate with geomembranes, the geo fabric near me presents a protecting cushioning layer and an nice filtration medium. It prevents punctures in geomembrane liners, lets in managed water drainage, and keeps filtration effectivity in leachate series systems. The geotextile’s chemical resistance and environmental protection make it an imperative issue in waste containment, mining, and environmental restoration projects.

Choose GEOSINCERE Geosynthetics Polypropylene Woven Geotextile

Shandong Geosino New Material Co., Ltd.(GEOSINCERE Geosynthetics)is a relied on producer and exporter of woven and nonwoven geotextiles. GEOSINCERE Geosynthetics’s Polypropylene Woven Geotextile combines superior weaving technology, strict ASTM/ISO first-rate control, and tailor-made specs to meet the most annoying engineering challenges. With validated overall performance throughout infrastructure, mining, and environmental safety tasks worldwide, GEOSINCERE Geosynthetics ensures durable, cost-effective, and sustainable floor solutions.