HDPE Geomembrane Sheet Price

The HDPE Geomembrane Sheet Price has become a key concern for international buyers, contractors, and project developers involved in infrastructure, aquaculture, mining, and environmental protection. As the global demand for waterproofing and containment solutions rises, the pricing of HDPE geomembranes is shaped by factors such as raw material cost fluctuations, energy prices, logistics, and regulatory standards.

Over the past three years, the geomembrane market has experienced price volatility due to variations in polyethylene resin supply, driven by crude oil trends and manufacturing costs. According to recent market data, the global geomembrane industry was valued at over USD 2.5 billion in 2024 and is projected to grow at a CAGR of 6.8% through 2030, with Asia-Pacific leading both production and consumption.

Global Overview of HDPE Geomembrane Sheet Price Trends

The HDPE Geomembrane Sheet Price has become a key concern for international buyers, contractors, and project developers involved in infrastructure, aquaculture, mining, and environmental protection. As the global demand for waterproofing and containment solutions rises, the pricing of HDPE geomembranes is shaped by factors such as raw material cost fluctuations, energy prices, logistics, and regulatory standards.

Over the past three years, the geomembrane market has experienced price volatility due to variations in polyethylene resin supply, driven by crude oil trends and manufacturing costs. According to recent market data, the global geomembrane industry was valued at over USD 2.5 billion in 2024 and is projected to grow at a CAGR of 6.8% through 2030, with Asia-Pacific leading both production and consumption.

Market Dynamics Influencing HDPE Geomembrane Sheet Price

Several key elements directly affect the HDPE Geomembrane Sheet Price:

1. **Raw Material Costs:** High-density polyethylene resin accounts for nearly 70% of total production costs. Any fluctuation in petrochemical feedstocks significantly impacts final pricing.

2. **Manufacturing Technology:** Modern extrusion and co-extrusion technologies enhance product performance but increase initial investment and operational costs.

3. **Thickness and Specification:** The most common thicknesses range from 0.5mm to 2.5mm. Heavier sheets with greater tensile strength and puncture resistance command higher prices.

4. **Geographical Factors:** Regional energy costs, labor rates, and shipping logistics all influence the total landed cost for international buyers.

Technical Parameters and Product Composition

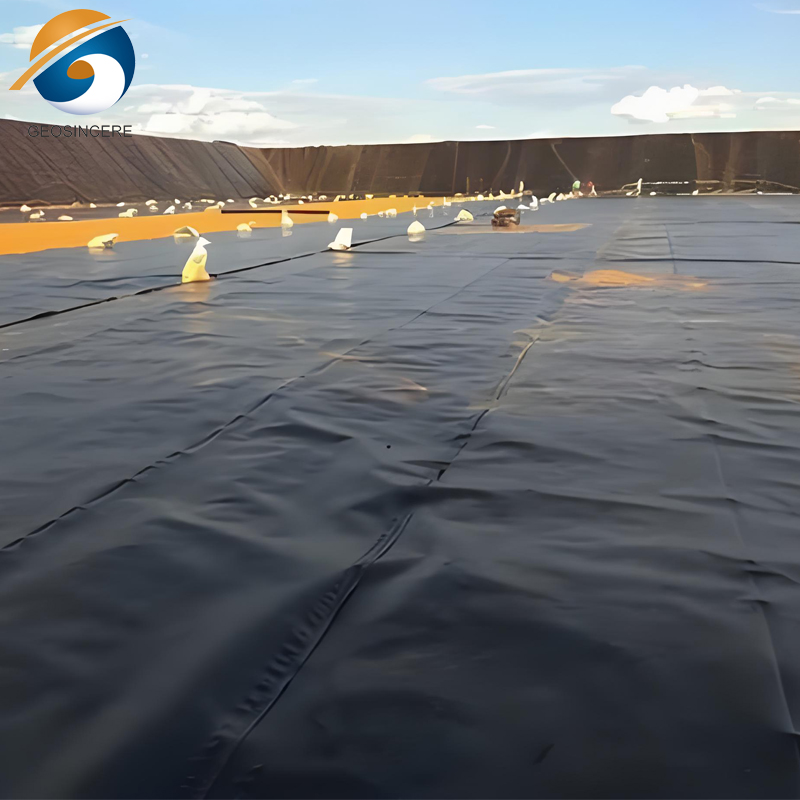

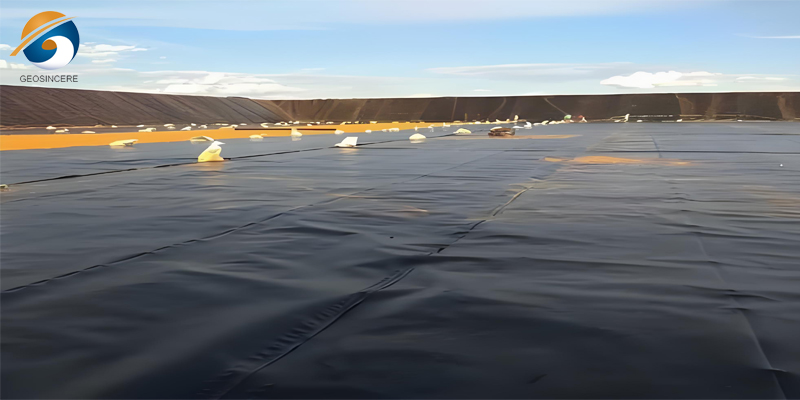

The HDPE geomembrane sheet is engineered for impermeability, chemical resistance, and mechanical durability. Technical specifications vary by project but typically include:

- Density: ≥0.94 g/cm³ - Tensile Strength at Yield: ≥27 MPa - Elongation at Break: ≥700% - Tear Resistance: ≥150 N - Carbon Black Content: 2–3% for UV protection

These parameters ensure consistent performance under extreme environmental conditions, making HDPE geomembranes ideal for applications such as landfill liners, aquaculture ponds, canal linings, and mining leach pads.

Manufacturing Process and Quality Control

HDPE geomembrane sheets are manufactured through high-temperature extrusion or blown film processes. The molten polymer is extruded into uniform sheets, then cooled and treated for surface smoothness or texturing, depending on the application.

Advanced production lines incorporate automatic thickness control and continuous defect detection systems. Each roll undergoes mechanical testing, oxidation induction testing (OIT), and hydrostatic pressure evaluation to ensure compliance with international standards such as ASTM, GRI-GM13, and ISO.

Global Market Segmentation and Price Comparison

The HDPE Geomembrane Sheet Price varies widely depending on region and supplier capabilities:

- **Asia-Pacific:** Competitive pricing due to large-scale manufacturing and abundant resin supply. Average price range: USD 1.2–2.5 per square meter.

- **Europe:** Higher due to stricter quality standards and higher labor costs, averaging USD 2.5–4.0 per square meter.

- **North America:** Prices typically range between USD 2.0–3.5 per square meter, influenced by logistics and certification requirements.

The increasing demand for sustainable materials has led to greater use of recycled or blended polyethylene, offering cost advantages but requiring rigorous testing to maintain quality assurance.

Buyer Preferences and Procurement Challenges

International buyers focusing on geomembrane liner cost often prioritize consistency, certification, and after-sales support over the lowest price. Procurement managers in mining, water management, and aquaculture sectors typically evaluate the following:

- Material origin and resin quality - Resistance to UV degradation and chemical exposure - Custom sizing and on-site welding guidance - Packaging, logistics, and lead times

Price-sensitive buyers from developing regions, particularly in Southeast Asia and Africa, seek flexible order volumes and mixed-container shipment options to optimize cost efficiency.

Emerging Trends and Future Outlook

The future of HDPE Geomembrane Sheet Price is closely tied to innovation and sustainability. Manufacturers are investing in energy-efficient production lines, bio-based resins, and enhanced carbon black dispersion technologies.

With growing government emphasis on environmental compliance, demand for certified geomembranes is expected to rise, driving standardization and transparency in global pricing. In parallel, digital procurement platforms are enabling buyers to compare quotations and technical data more efficiently than ever before.

Frequently Asked Questions (FAQ)

1. What factors have the greatest impact on HDPE Geomembrane Sheet Price?

Raw material costs, sheet thickness, and regional production expenses are the most significant pricing drivers.

2. What is the standard lifespan of an HDPE geomembrane sheet?

When properly installed and maintained, premium geomembranes can last 15–20 years in outdoor applications.

3. Are there minimum order requirements for export buyers?

Most suppliers offer flexible MOQ options ranging from 5,000 to 10,000 square meters, depending on customization and logistics.

4. How can buyers verify product quality before shipment?

Request a full technical data sheet, third-party inspection reports, and sample testing prior to final order confirmation.

Request a Quotation or Technical Data Sheet

We provide comprehensive solutions for HDPE Geomembrane Sheets tailored to your project’s environmental and structural requirements. Our team offers customized pricing analysis, material recommendations, and sample testing for global buyers.

Contact us today to receive an updated HDPE Geomembrane Sheet Price quotation, detailed specifications, and professional installation support for your upcoming project.