Geomembrane HDPE 2mm

The global demand for Geomembrane HDPE 2mm continues to rise as large-scale infrastructure, mining operations, solid waste containment, and aquaculture projects increasingly prioritize impermeable lining solutions. As environmental compliance standards tighten and engineered barrier systems become central to modern construction practices, HDPE geomembranes have become the preferred material for long-term containment and environmental protection.

Market data from recent international reports indicates steady growth for geomembranes, with accelerated adoption in regions implementing stricter leachate, groundwater, and chemical-containment regulations. Geomembrane HDPE 2mm is particularly sought after for its balance of tensile strength, durability, and chemical resistance, making it a standard specification for high-stress containment environments including landfills, tailings dams, industrial reservoirs, and biogas digesters.

Global Market Overview of Geomembrane HDPE 2mm

The global demand for Geomembrane HDPE 2mm continues to rise as large-scale infrastructure, mining operations, solid waste containment, and aquaculture projects increasingly prioritize impermeable lining solutions. As environmental compliance standards tighten and engineered barrier systems become central to modern construction practices, HDPE geomembranes have become the preferred material for long-term containment and environmental protection.

Market data from recent international reports indicates steady growth for geomembranes, with accelerated adoption in regions implementing stricter leachate, groundwater, and chemical-containment regulations. Geomembrane HDPE 2mm is particularly sought after for its balance of tensile strength, durability, and chemical resistance, making it a standard specification for high-stress containment environments including landfills, tailings dams, industrial reservoirs, and biogas digesters.

Industry Trends and Global Adoption Drivers

Several key trends are shaping the widespread use of Geomembrane HDPE 2mm across global engineering sectors. A major driver is the increasing need for cost-effective environmental protection systems that meet international engineering standards such as GRI-GM13. Rising mining activity, water conservation initiatives, and rapid expansion of waste-treatment infrastructure further strengthen the material’s relevance.

Technological advancements in extrusion, blown-film production, and automated welding systems are also improving product consistency, field installation quality, and long-term performance reliability. Additionally, the global shift toward renewable energy projects has increased geomembrane use in applications such as biogas digesters, slurry tanks, and lagoon linings.

Technical Specifications and Mechanical Performance

Geomembrane HDPE 2mm is designed to deliver high tensile strength, superior impermeability, and strong chemical resistance. Common technical parameters include tensile yield strength, elongation at break, tear resistance, puncture resistance, carbon-black content, and hydrostatic pressure tolerance. The thickness of 2mm is ideal for applications requiring enhanced puncture resistance and stability under geomaterial loads.

International buyers often review properties such as UV stability, stress-crack resistance, multi-axial tear strength, permeability rate, and weldability. These criteria ensure performance across extreme temperatures, aggressive chemicals, and long-term outdoor exposure. The membrane’s high carbon-black formulation is essential for preventing UV degradation during extended service life.

Product Structure and Material Composition

Geomembrane HDPE 2mm is produced from high-density polyethylene resins with strict control over density, molecular weight distribution, and additive formulation. Its structure is a single-layer, high-strength sheet produced by either blown-film or flat-die extrusion, depending on processing technology and application requirements.

Key material characteristics—such as flexibility, stress cracking resistance, and environmental stress tolerance—are influenced by resin quality and the precision of thermal processing. Additives including antioxidants and UV stabilizers extend operational lifespan under demanding field conditions.

Manufacturing Process and Quality Assurance

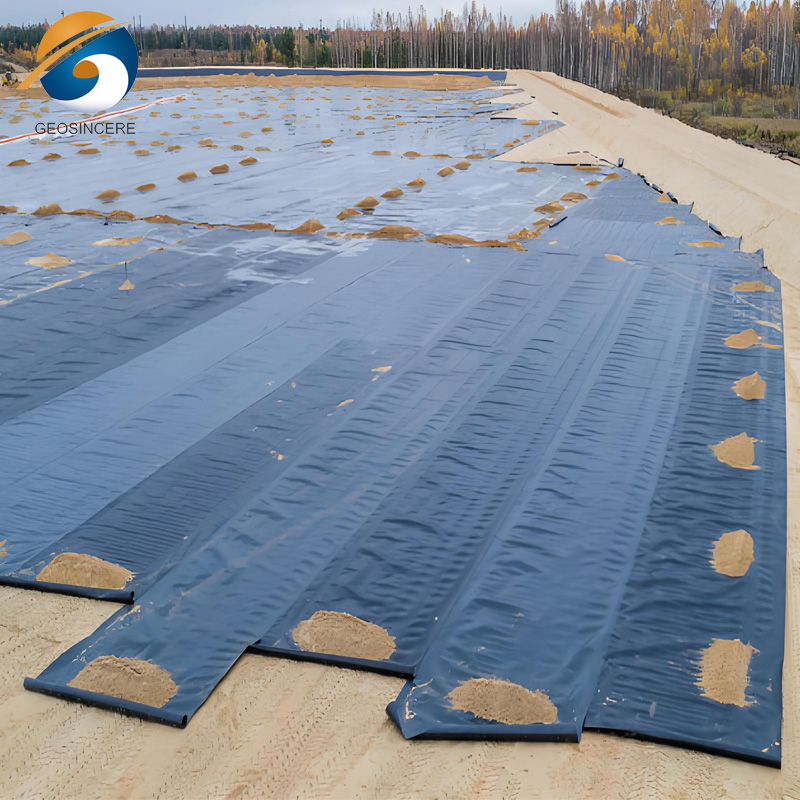

The production of Geomembrane HDPE 2mm follows a controlled extrusion process. Pellets are melted, homogenized, and extruded into a uniform sheet thickness through advanced machinery. Real-time laser measurement systems ensure tight thickness tolerances, which are critical for achieving consistent sealing performance during installation.

Quality control includes mechanical and environmental testing such as thickness verification, tensile testing, oxidative induction time (OIT), carbon-black dispersion, and dimensional stability analysis. These procedures ensure compliance with international technical standards and enable reliable field welding performance.

Applications Across Engineering and Environmental Projects

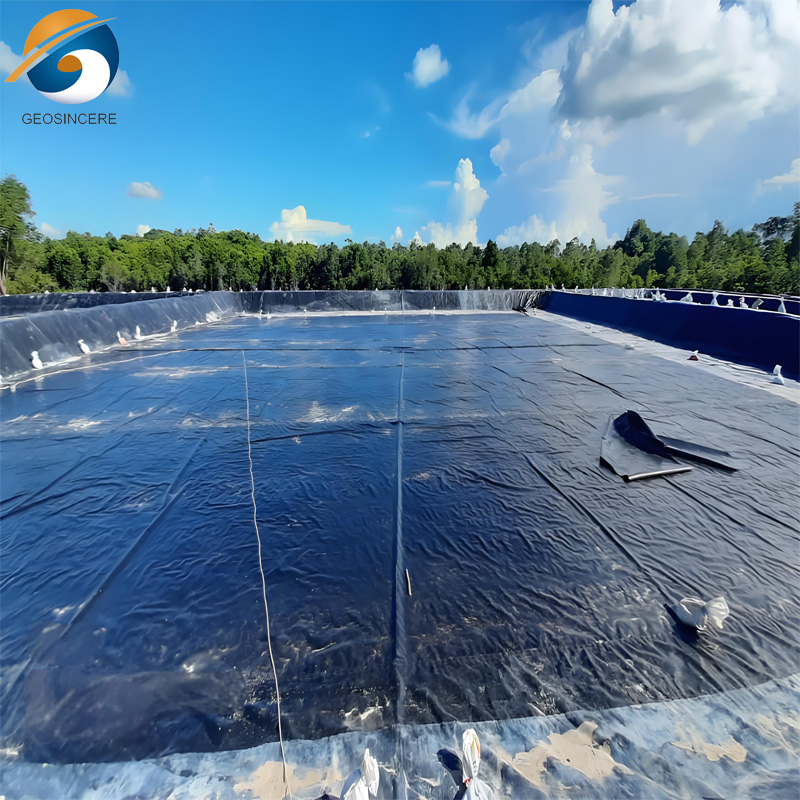

Geomembrane HDPE 2mm is widely used in landfill liners, mining heap leach pads, wastewater treatment basins, aquaculture ponds, and irrigation reservoirs. Its structural integrity and impermeability make it suitable for applications involving hydraulic pressure, abrasive materials, and long-term chemical exposure.

In mining operations, the membrane prevents chemical infiltration into groundwater, while in wastewater and industrial containment, it provides reliable resistance against corrosive liquids. In agricultural environments, the material serves as an effective lining for ponds and water storage systems, supporting long operational cycles with minimal maintenance.

Global Buyer Preferences and Procurement Challenges

Buyers sourcing Geomembrane HDPE 2mm prioritize thickness stability, mechanical performance, clean welding characteristics, and certification compliance. Consistency across production batches is essential, especially for large-scale installations requiring seamless overlap welding.

Common procurement concerns include inconsistent roll width, inadequate packaging for long-distance shipping, and variable thickness tolerance affecting installation quality. To meet these expectations, suppliers must ensure controlled production, detailed technical documentation, reliable shipment protection, and responsive engineering support.

Market Outlook and Strategic Considerations

With global demand rising steadily, Geomembrane HDPE 2mm remains one of the most widely specified geomembrane thicknesses for high-strength containment. Growth trajectories indicate increasing adoption in developing regions as infrastructure investment intensifies. Sustainability initiatives are also driving demand for longer-lasting lining systems that minimize environmental risks.

We provide industry-specific consulting, technical datasheets, and customized specifications to help buyers evaluate suitable thickness, mechanical performance, and installation standards for their projects. Our expert team supports procurement decisions with comprehensive documentation and sample evaluation.

FAQ

What applications require Geomembrane HDPE 2mm?

This thickness is commonly used for landfills, mining leach pads, wastewater treatment basins, and reservoirs requiring enhanced puncture resistance.

How does 2mm HDPE geomembrane perform under UV exposure?

High carbon-black content and stabilizers allow 2mm HDPE geomembranes to maintain performance even under prolonged direct sunlight.

Is 2mm thickness suitable for heavy-load environments?

Yes. The 2mm specification offers high tensile strength and puncture resistance, making it suitable for applications involving overburden loads.

Can buyers request customized roll sizes?

Custom roll widths, lengths, and technical parameters can be produced based on project requirements and order quantity.

To obtain a detailed quotation, technical data sheets, or material samples tailored to your engineering project, contact us for professional support and customized solutions.