8 Oz Geotextile Fabric

The 8 oz geotextile material is a sturdy and versatile material, meticulously crafted from wonderful needle-punched polypropylene. This material is designed to provide superb filtration, drainage, and separation capabilities, making it a go-to preference for a range of civil engineering and environmental applications. With a weight of eight oz per rectangular yard (271 g/m²), it strikes a ideal stability between electricity and permeability. Its tensile electricity of 205 kilos (0.911 kN) ensures it can face up to vast loads, whilst its water drift charge of ninety gpm/ft² (3657 l/min/m²) guarantees environment friendly drainage. The fabric additionally boasts a puncture resistance of a hundred thirty kilos (0.578 kN), offering sturdy safety towards punctures. Its excessive resistance to UV rays and organic degradation, alongside with its capability to face up to a large vary of chemicals, makes it appropriate for long-term outside use in harsh environments.

This geotextile material is perfect for purposes such as roadway stabilization, the place it enhances the balance of street bases and prevents soil erosion. It is additionally regularly used in French drain systems, performing as a filter to stop soil from clogging drainage systems. For soil erosion control, it presents advantageous safety in opposition to erosion on hillsides and riverbanks, and it can additionally limit wind erosion in uncovered areas. In restoration projects, it helps soil stabilization and prevents erosion, whilst its separation skills make it an positive barrier between specific layers of soil or between soil and gravel. Additionally, it serves as a sediment filter in drainage systems, stopping clogging and making sure easy water flow.

The 8 oz geotextile fabric is not only durable and functional but also cost-effective. Its lightweight and flexible nature makes it easy to handle and install, reducing labor costs and time. It meets stringent industry standards, ensuring reliability and long-term performance. Whether you are working on a large-scale infrastructure project, a landscaping initiative, or a small home improvement task, the 8 oz geotextile fabric is a reliable and versatile solution that can significantly enhance the stability, drainage, and overall effectiveness of your project.

This fabric is available in large rolls, typically measuring 15 feet in width and 300 feet in length, providing 5,400 square feet of coverage per roll. Its applications are extensive and varied, making it an essential component in numerous civil engineering and environmental projects. It is commonly used for soil stabilization in road construction, preventing the underlying soil from shifting and ensuring the road’s structural integrity. In drainage systems, such as French drains, the 8 oz geotextile fabric acts as a filter, preventing soil particles from clogging the drainage pipes while allowing water to pass through freely. It is also highly effective in erosion control, protecting slopes and riverbanks from soil erosion caused by water runoff. The fabric can be used to separate different layers of soil or aggregate, preventing them from mixing and maintaining the desired engineering properties of each layer. In sediment filtration applications, it helps to trap sediment while allowing water to flow through, reducing sedimentation in water bodies and protecting aquatic habitats.

Parameter

Item | Test Method | Unit | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

Index Properties | ||||||||||||

Ultimate Tensile Strength. MD | ASTM D4595 | KN/m | 1 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength. MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength. MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size 090 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | G/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Roll width | / | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Roll Length | / | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |

Advantages of 8 Oz Geotextile Fabric

8 oz geotextile fabric is a nonwoven geosynthetic material widely used in civil engineering, drainage, erosion control, and road stabilization applications. As a mid-weight option, it offers an ideal balance of tensile strength, filtration capacity, and durability. This article provides a detailed technical guide on 8 oz geotextile fabric—its material composition, functions, compliance standards, and how to select the right product and manufacturer.

Table of Contents

What Is 8 Oz Geotextile Fabric?

Technical Specifications

Engineering Applications

Material Composition and Manufacturing Process

Industry Standards and Regulatory Compliance

Installation Guidelines and Operational Considerations

Common Issues and Mitigation

Frequently Asked Questions (FAQs)

Conclusion & Call to Action

1. What Is 8 Oz Geotextile Fabric?

8 oz geotextile fabric refers to a nonwoven polypropylene or polyester geotextile with a weight of 8 ounces per square yard (approx. 270 g/m²). It is designed to perform multiple geotechnical functions, including:

Separation – Preventing intermixing of materials like subgrade and aggregates

Filtration – Allowing water to pass while retaining soil particles

Reinforcement – Distributing loads and improving soil stability

Protection – Acting as cushioning layer above geomembranes

Drainage – Facilitating subsurface water flow

2. Technical Specifications

| Property | Typical Value (8 oz fabric) | Test Method |

|---|---|---|

| Mass per Unit Area | 270 g/m² (8 oz/yd²) | ASTM D5261 |

| Grab Tensile Strength | ≥ 205 lbs (912 N) | ASTM D4632 |

| Elongation at Break | ≥ 50% | ASTM D4632 |

| Puncture Resistance | ≥ 500 lbs (2,224 N) | ASTM D6241 |

| Permittivity | ≥ 0.7 sec⁻¹ | ASTM D4491 |

| Water Flow Rate | ≥ 90 gpm/ft² (3,666 L/min/m²) | ASTM D4491 |

| AOS (Apparent Opening Size) | 0.21 mm (U.S. Sieve #70) | ASTM D4751 |

| UV Resistance (500 hrs) | ≥ 70% strength retained | ASTM D4355 |

3. Engineering Applications

8 oz nonwoven geotextile fabric is a versatile mid-grade material used in both permanent and temporary civil infrastructure works. Common uses include:

Under Riprap & Gabions: Acts as a filter and separator, preventing soil migration

French Drains & Subsurface Drainage: Allows high flow while trapping fines

Roadway Stabilization: Provides separation and load distribution between aggregate and soil

Retaining Walls: Prevents backfill loss and ensures structural integrity

Landfill Construction: Protects geomembranes and facilitates leachate drainage

Erosion Control: Underlay for erosion control blankets, slope stabilization mats, etc.

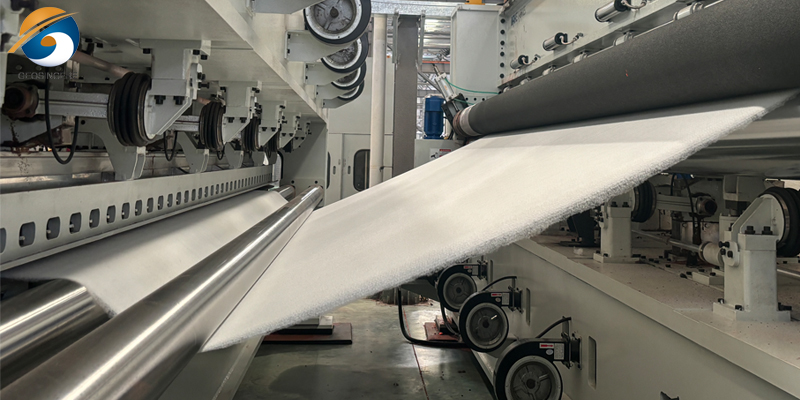

4. Material Composition and Manufacturing Process

Raw Material: Typically made from 100% UV-stabilized polypropylene or polyester resin.

Manufacturing Process:

Needle punching is the most common technique, mechanically entangling the fibers for high permeability and strength.

Some variants include thermal bonding to increase puncture resistance.

The final product is typically rolled and shipped in widths ranging from 3.5 to 6 meters, with roll lengths of 50–100 meters.

5. Industry Standards and Regulatory Compliance

A qualified 8 oz geotextile fabric manufacturer should comply with the following standards:

| Standard / Code | Description |

|---|---|

| ASTM D4759 | Standard Guide for Quality Control for Geotextiles |

| AASHTO M288-17 | U.S. Department of Transportation specification for road projects |

| ISO 10318 & 12956 | International standards for geotextile terminology and filtration |

| CE Certification (EN 13249 – EN 13257) | For European markets |

| GRI-GT12 | Guidelines for nonwoven geotextile specification by the Geosynthetic Institute |

Ensure the product is free from recycled contaminants

For environmentally sensitive projects, ensure it is compliant with RoHS and REACH

6. Installation Guidelines and Operational Considerations

Site Preparation:

Remove debris, rocks, and sharp objects. Ensure subgrade is graded and compacted.

Fabric Deployment:

Roll out the geotextile with minimal wrinkles.

Overlap adjacent sheets by 12"–18" (30–45 cm) or as per project specifications.

Anchoring:

Use pins or trenching for anchorage in high-flow or slope applications.

Backfill and Cover:

Avoid driving equipment directly on the fabric. Use cover material of minimum 150 mm (6 inches) thickness before compaction.

Welding/Seaming:

Generally unnecessary for nonwoven geotextiles; overlaps suffice. However, heat bonding or stitched seams may be used in critical containment projects.

7. Common Issues and Mitigation

| Issue | Cause | Solution |

|---|---|---|

| Puncturing during installation | Sharp rocks or construction traffic | Use thicker geotextile or apply protective sand layer |

| Clogging in filtration zones | Fines bypassing AOS limits | Select appropriate AOS based on soil gradation (per ASTM D5101) |

| UV degradation | Prolonged exposure | Ensure timely cover or use UV-stabilized fabric |

| Edge slippage on slopes | Inadequate anchoring | Increase trench depth or use soil nails/geopins |

8. Frequently Asked Questions (FAQs)

Q1: What is the lifespan of 8 oz geotextile fabric?

When buried or protected from UV, it can last 50+ years. Exposed use requires UV-stabilized versions and should be temporary (<6 months).

Q2: Is 8 oz suitable for heavy-duty road construction?

Yes. It meets or exceeds AASHTO Class 2 separation and filtration requirements for most subgrade conditions.

Q3: Can it be used under gravel or pavers?

Absolutely. It prevents subgrade mixing and improves load-bearing capacity while allowing water drainage.

Q4: How to choose between woven and nonwoven geotextiles?

Use nonwoven for drainage and filtration, woven for high tensile reinforcement.

Q5: Does it support plant growth?

No. It is not biodegradable and is used under landscaping fabric to suppress weed growth or support drainage.

9. Conclusion & Call to Action

8 oz geotextile fabric is a high-performance, mid-weight solution engineered for critical civil, drainage, and erosion control applications. It offers an optimal balance of strength, flow rate, and soil retention, making it suitable for infrastructure projects with medium to heavy load demands.

When sourcing geotextiles, ensure that your supplier provides:

Full technical datasheets

ASTM / ISO compliant testing

On-site support and engineering consultation

Traceability and quality assurance certificates