High Density Polyethylene 2mm HDPE Geomembrane Liner

High Density Polyethylene 2mm HDPE geomembrane liner has become a standard solution for containment and waterproofing in mining, landfill, aquaculture, irrigation and wastewater projects. As environmental regulations tighten and infrastructure investment grows, demand for engineered liners capable of long-term impermeability has increased worldwide.

Market analysis shows steady growth in regions including Southeast Asia, the Middle East, Latin America and Africa, where large-scale water retention and waste-control projects drive procurement needs. Procurement teams now evaluate not only the High Density Polyethylene 2mm HDPE geomembrane liner price but also verified mechanical performance and long-term durability under local conditions.

Global Market Environment for High Density Polyethylene 2mm HDPE Geomembrane Liner

High Density Polyethylene 2mm HDPE geomembrane liner has become a standard solution for containment and waterproofing in mining, landfill, aquaculture, irrigation and wastewater projects. As environmental regulations tighten and infrastructure investment grows, demand for engineered liners capable of long-term impermeability has increased worldwide.

Market analysis shows steady growth in regions including Southeast Asia, the Middle East, Latin America and Africa, where large-scale water retention and waste-control projects drive procurement needs. Procurement teams now evaluate not only the High Density Polyethylene 2mm HDPE geomembrane liner price but also verified mechanical performance and long-term durability under local conditions.

Key Drivers and Industry Trends

Major trends shaping the geomembrane sector include stricter environmental compliance, expansion of aquaculture and irrigation infrastructure, and adoption of engineered liners in mining operations. Buyers searching for the High Density Polyethylene 2mm HDPE geomembrane liner increasingly use long-tail queries such as “HDPE pond liner 2mm”, “geomembrane for landfill lining”, “2mm HDPE liner for aquaculture”, “waterproof HDPE sheet price”, and “HDPE canal lining membrane” to compare supplier capabilities and cost-effectiveness.

Another important trend is the preference for textured finishes when slope friction is critical, and for co-extruded variants when multi-functional performance is required. These technical choices influence procurement cycles and final pricing.

Technical Specifications of the 2mm HDPE Geomembrane Liner

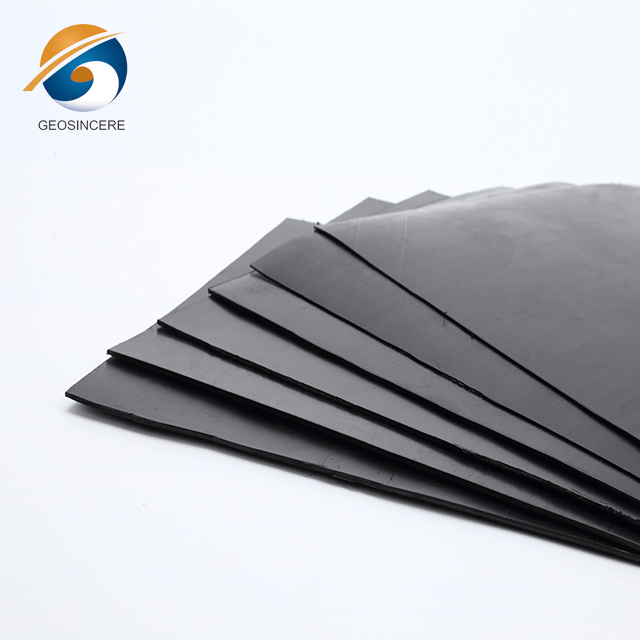

The High Density Polyethylene 2mm HDPE geomembrane liner typically features a density range of 0.94–0.97 g/cm³, with carbon black content around 2%–3% for UV protection. Standard mechanical properties for quality liners include tensile strength ≥25 MPa, elongation at break ≥600%–700%, and low permeability (≤10⁻¹³–10⁻¹⁴ m/s). Thickness tolerance and uniformity are critical: a certified 2mm sheet must meet narrow gauge deviations across the roll width to ensure predictable field performance.

Chemical resistance to acids, alkalis, oils and salts is a major parameter for mining and industrial wastewater applications, while environmental stress crack resistance (ESCR) and oxidative induction time (OIT) are essential indicators of expected service life.

Product Structure and Variants

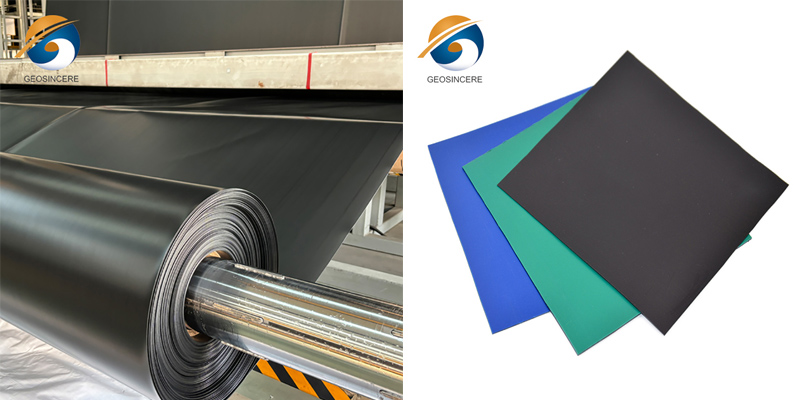

The 2mm geomembrane is available as homogeneous mono-layer sheets or as multi-layer co-extruded products. Smooth-surface 2mm HDPE liners are common for reservoirs and ponds, whereas textured or roughened surfaces increase interface friction for steep embankments and slope stabilization. Co-extruded configurations can include a modified surface layer to enhance weldability or chemical resistance, which affects both performance and price.

Manufacturing Process and Quality Assurance

Production of the High Density Polyethylene 2mm HDPE geomembrane liner follows stringent extrusion practices. The process includes resin selection (preferring ≥97% virgin HDPE for critical projects), melt extrusion through blown-film or flat-die lines, precision gauge control, and inline defect detection.

Quality assurance includes tensile and elongation testing, puncture and tear resistance testing, ESCR assessment, OIT measurement, carbon black dispersion checks, and permeability tests. Many international buyers require independent lab reports and compliance with GRI-GM13, ASTM or ISO standards prior to award. Thorough QA reduces onsite risk and avoids costly remediation or rework.

Applications and Installation Considerations

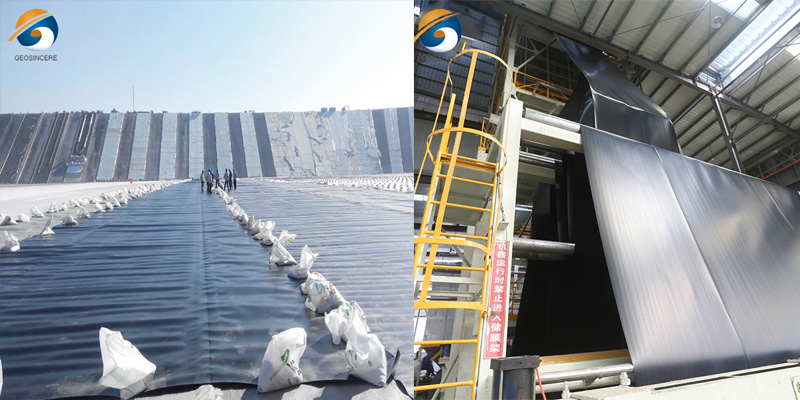

The High Density Polyethylene 2mm HDPE geomembrane liner is used for irrigation reservoirs, fish and shrimp ponds, stormwater basins, landfill interim covers, canal lining, and secondary containment systems. For aquaculture ponds, 2mm thickness balances cost and robustness, providing adequate puncture resistance and impermeability for medium-sized installations. In mining, the 2mm liner is often applied in less aggressive containment zones or as a secondary layer beneath thicker primary liners.

Installation practices—such as surface preparation, welding technique (hot wedge or extrusion), seam testing, and anchoring—are decisive factors for lifecycle performance. International buyers increasingly request supplier-provided welding training, on-site supervision, and third-party seam testing to ensure integrity.

Procurement Preferences and Common Pain Points

Buyers prioritize traceable raw material documentation, consistent thickness delivery, verified mechanical properties, and reliable logistics. Key expectations for the High Density Polyethylene 2mm HDPE geomembrane liner include: certified test reports, flexible roll widths to minimize field welding, UV stabilization data, and long-term supply commitments for phased projects.

Frequent procurement challenges include inconsistent resin grades among suppliers, variable thickness tolerance, inadequate packaging causing transport damage, and poor after-sales technical support. Clear technical datasheets, sample provision, and responsive engineering assistance are decisive in supplier selection.

Pricing Factors and Market Outlook

Price for the High Density Polyethylene 2mm HDPE geomembrane liner depends on resin market trends, carbon black costs, production technology, surface treatment (textured vs smooth), third-party certification, and order volume. While resin price volatility can affect short-term quotations, long-term value is driven by product performance and reduced lifecycle maintenance costs. The global outlook remains positive as demand for engineered containment materials grows with urbanization and environmental remediation programs.

Conclusion and Action Steps

The High Density Polyethylene 2mm HDPE geomembrane liner offers a pragmatic balance of durability, impermeability, and cost-efficiency for many civil and industrial containment needs. For international procurement teams, ensuring supplier transparency, test-certification and installation support is essential to secure project success.

If you require project-specific specifications, independent test reports, roll sample evaluation or a customized quotation for the High Density Polyethylene 2mm HDPE geomembrane liner, contact our technical team for detailed documentation and on-site engineering support.

FAQ

Q1: Is 2mm HDPE suitable for aquaculture ponds?

Yes. For many medium-scale aquaculture installations, 2mm provides an effective balance of impermeability and puncture resistance.

Q2: What welding methods are recommended?

Hot-wedge welding and extrusion welding are standard practice; seam testing (vacuum or air channel) is recommended to verify seam integrity.

Q3: How is service life estimated?

Service life depends on material quality, UV exposure, chemical environment and installation; high-quality 2mm HDPE liners can last 10–25 years under normal conditions.

Q4: Can suppliers provide custom roll widths?

Yes. Custom roll widths reduce onsite seam lengths and are commonly offered for large projects to improve installation efficiency.