Geotextile Separation Underlayment Permeable Filter Fabric

The primary function of geotextile separation underlayment is to create a barrier between different layers of soil or aggregate materials, preventing them from mixing or intermixing. By providing separation, it helps to maintain the integrity and stability of the constructed layers. For example, it can be used to separate the subsoil from the aggregate base in road construction or to separate different layers of soil in a retaining wall.

Permeable filter fabric also acts as a filtration medium by allowing water to pass through while preventing the migration of fine particles or soil fines. This property is beneficial in applications where drainage is required while preventing the clogging of underlying drainage systems or structures. The geotextile's permeability allows water to flow through, reducing the buildup of hydrostatic pressure and preventing the loss of soil fines.

When it comes to achieving long-lasting soil stabilization, erosion control, and effective drainage, Geotextile Separation Underlayment Permeable Filter Fabric plays a vital role in modern civil engineering and landscaping projects. This high-performance synthetic fabric is specifically engineered to separate, reinforce, filter, and protect soil structures in both residential and commercial infrastructure developments.

What is Geotextile Separation Underlayment Permeable Filter Fabric?

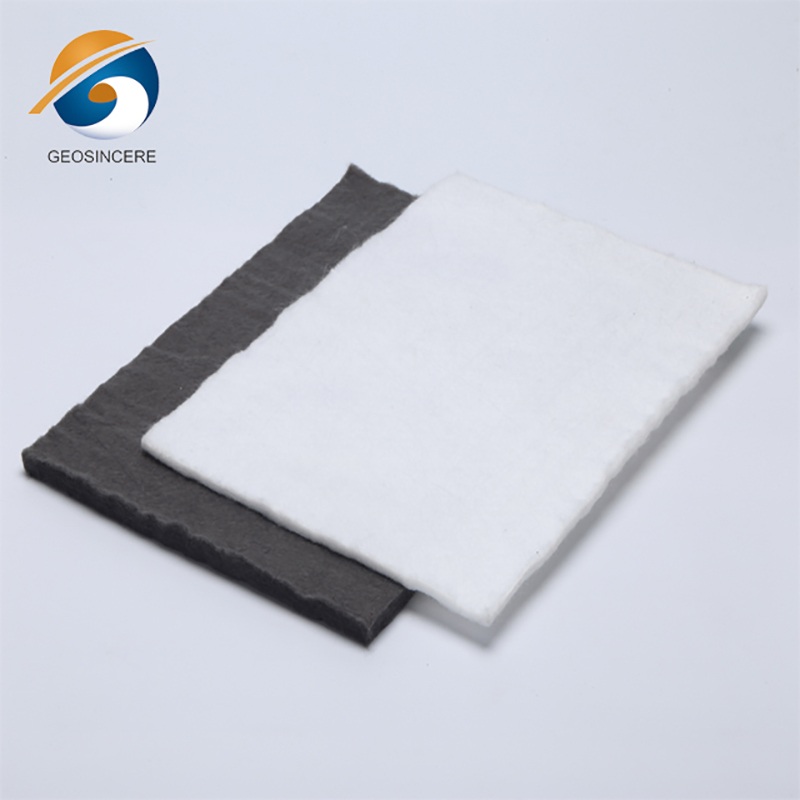

Geotextile Separation Underlayment Permeable Filter Fabric is a robust and permeable textile material made from polypropylene or polyester. It is commonly used beneath roads, pavers, driveways, retaining walls, and drainage systems. Its core function is to prevent the mixing of soil layers, facilitate water filtration, and extend the life of paved and unpaved surfaces.

This advanced geosynthetic solution acts as a separator between subgrade and base materials, making it ideal for projects where soil integrity and water flow are critical.

Key Features of Geotextile Separation Underlayment Permeable Filter Fabric

✅ Excellent Permeability

The permeable structure of the Geotextile Separation Underlayment Permeable Filter Fabric allows water to pass through while blocking the movement of soil particles, thus preventing clogging and water accumulation.

✅ Soil Stabilization

It provides crucial stabilization by separating fine soil from aggregates, reducing rutting and structural failure in load-bearing areas like roads and parking lots.

✅ UV and Chemical Resistance

Designed to withstand exposure to sunlight, alkaline soils, and various contaminants, it ensures long-term durability even in harsh environments.

✅ Easy to Install

Lightweight, flexible, and easy to cut and roll out, Geotextile Separation Underlayment Permeable Filter Fabric is user-friendly and reduces installation time and cost.

✅ Eco-Friendly and Cost-Effective

Its use reduces the need for excessive fill materials and extends the life of infrastructure, offering a high return on investment.

Main Applications of Geotextile Separation Underlayment Permeable Filter Fabric

The Geotextile Separation Underlayment Permeable Filter Fabric is an essential product in the construction and landscaping industries, suitable for:

🟢 Driveways & Road Construction

🟢 French Drains & Trench Drainage

🟢 Retaining Walls

🟢 Garden Landscaping & Erosion Control

🟢 Paver and Patio Base Stabilization

🟢 Railway Subgrade Support

🟢 Landfill and Stormwater Management Systems

From large-scale infrastructure to residential projects, this versatile fabric helps improve foundation performance while ensuring proper drainage.

Technical Specifications

| Property | Value |

|---|---|

| Product Name | Geotextile Separation Underlayment Permeable Filter Fabric |

| Material | Woven / Nonwoven Polypropylene / Polyester |

| Weight | 100gsm – 600gsm |

| Width | 1m – 6m (customizable) |

| Permeability | ≥ 10⁻³ cm/s |

| UV Resistance | Excellent (UV stabilized) |

| Tensile Strength | ≥ 8 kN/m to ≥ 50 kN/m |

| Elongation | ≤ 50% |

| Color | Black / White / Grey |

| Lifespan | Up to 25+ years (when buried) |

| Standards | ASTM D-4491, D-4632, ISO 10319 |

Why Choose Geotextile Separation Underlayment Permeable Filter Fabric?

Choosing Geotextile Separation Underlayment Permeable Filter Fabric ensures that your construction project maintains its structural integrity while allowing proper drainage. Whether you’re working on a simple garden path or a multi-million-dollar roadway, this filter fabric is engineered to:

Prevent soil contamination and mixing

Improve load distribution

Support long-term drainage

Mitigate erosion

Prolong the life of paved structures

By investing in high-quality Geotextile Separation Underlayment Permeable Filter Fabric, you are ensuring sustainability, functionality, and cost-efficiency.

Installation Tips

Site Preparation: Clear the installation area of vegetation, rocks, and debris.

Roll Out the Fabric: Place the Geotextile Separation Underlayment Permeable Filter Fabric directly over the prepared surface.

Overlap Edges: Ensure overlaps of 30–60 cm where multiple rolls are used.

Secure in Place: Use landscape staples or pins to anchor the fabric.

Add Base Materials: Backfill with gravel, sand, or other specified aggregates.

Proper installation will maximize the performance of the fabric and reduce maintenance needs.

Conclusion

Geotextile Separation Underlayment Permeable Filter Fabric is the smart choice for professionals who require reliable soil separation, excellent filtration, and structural reinforcement. Its adaptability across a range of projects, from highway construction to backyard landscaping, makes it an industry essential.

Parameter

Item | Test Method | Unit | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

Index Properties | ||||||||||||

Ultimate Tensile Strength. MD | ASTM D4595 | KN/m | 1 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength. MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength. MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size 090 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | G/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Roll width | / | m | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

Roll Length | / | m | 300 | 200 | 150 | 100 | 100 | 100 | 80 | 80 | 50 | 50 |

Geotextile Separation Underlayment Permeable Filter Fabric for Sale Features

Here's a breakdown of the key characteristics and purposes of geotextile separation underlayment:

1. Separation: Geotextile separation underlayment is primarily used to separate different layers of soil or aggregate materials with varying particle sizes. It prevents the mixing and migration of fine particles into coarser layers, thereby maintaining the integrity and stability of the structure. It prevents the loss of granular materials into soft subgrades, thereby enhancing the overall performance of the construction.

2. Filtration: The permeable filter fabric allows water to pass through while retaining soil particles. It acts as a filtration layer by preventing clogging of underlying drainage systems or geotechnical features. By providing filtration, it ensures the free flow of water while preventing the migration of fine particles and potential soil erosion.

3. Reinforcement: Geotextile separation underlayment can also provide reinforcement to the soil or aggregate layers. It distributes the loads and reduces the potential for differential settlement, thereby enhancing the overall stability and strength of the construction. It can be used to reinforce embankments, retaining walls, roadways, and other geotechnical structures.

4. Permeability: The permeable nature of the geotextile allows water to pass through it, which is essential for effective drainage and groundwater management. It helps to maintain the hydraulic conductivity of the soil or aggregate layers and prevents the buildup of hydrostatic pressure.

Applications of Geotextile Separation Underlayment Permeable Filter Fabric