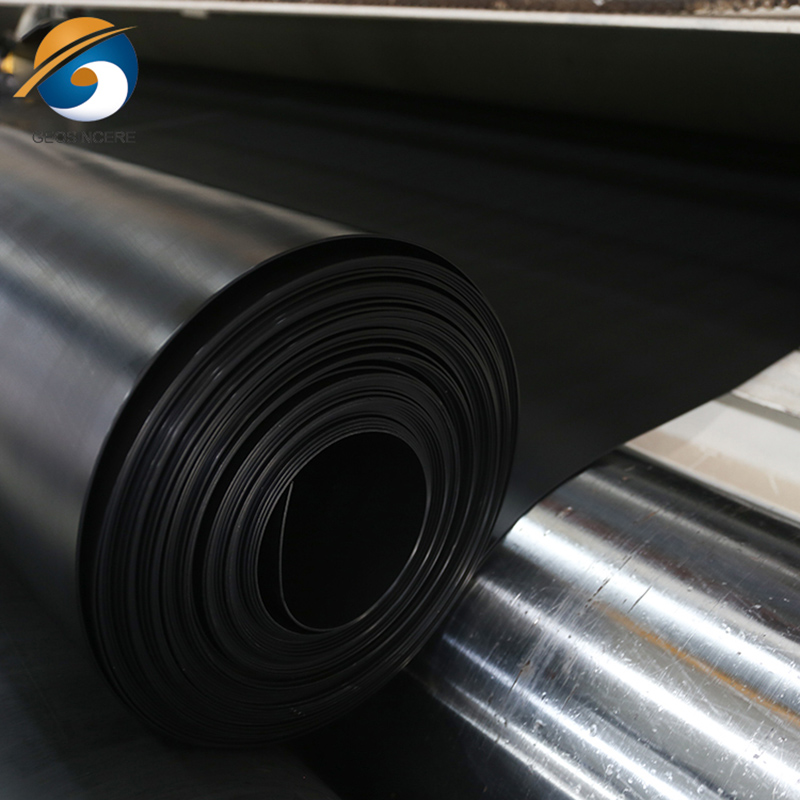

Dam Plastic HDPE Pond Liner Material

Manufacturing Process

The manufacturing process of Dam Plastic HDPE Pond Liner Material is highly controlled to ensure uniform thickness, mechanical performance, and weldability on site.

Engineering Manufacturing Steps

HDPE resin and additives batch formulation

High-speed mixing and drying

Flat die or blown film extrusion

Calendering and thickness control

Surface embossing or smooth finishing

Online thickness and defect inspection

Roll cutting, labeling, and packaging

Automated extrusion lines, gravimetric dosing systems, and online scanning devices are critical to meeting engineering-grade quality requirements.

Product Definition

Dam Plastic HDPE Pond Liner Material is a high-density polyethylene geomembrane designed for water containment, seepage control, and environmental protection in dams, reservoirs, ponds, and hydraulic engineering projects. It provides long-term impermeability, chemical resistance, and structural stability under demanding field conditions.

Technical Parameters and Specifications

The following technical parameters are commonly specified in dam and pond engineering tenders and must comply with international geomembrane standards.

Material: High-Density Polyethylene (HDPE)

Thickness range: 0.5 mm – 3.0 mm

Standard roll width: 5.0 m – 8.0 m

Standard roll length: 50 m – 100 m

Density: ≥ 0.94 g/cm³

Tensile strength at yield: ≥ 15 MPa

Elongation at break: ≥ 700%

Puncture resistance: ≥ 480 N

Carbon black content: 2.0% – 3.0%

UV resistance: ≥ 90% retained after 1600 h exposure

Service temperature range: -40°C to +60°C

Structure and Material Composition

Dam Plastic HDPE Pond Liner Material features a homogeneous single-layer structure engineered for maximum impermeability and durability.

Material Composition Breakdown

HDPE Resin: Primary structural component ensuring tensile strength and flexibility

Carbon Black: Provides UV resistance and long-term weatherability

Antioxidants: Prevent thermal and oxidative degradation

Processing Stabilizers: Ensure consistent extrusion and uniform thickness

Manufacturing Process

The manufacturing process of Dam Plastic HDPE Pond Liner Material is highly controlled to ensure uniform thickness, mechanical performance, and weldability on site.

Engineering Manufacturing Steps

HDPE resin and additives batch formulation

High-speed mixing and drying

Flat die or blown film extrusion

Calendering and thickness control

Surface embossing or smooth finishing

Online thickness and defect inspection

Roll cutting, labeling, and packaging

Automated extrusion lines, gravimetric dosing systems, and online scanning devices are critical to meeting engineering-grade quality requirements.

Industry Comparison

HDPE pond liners are often compared with alternative geomembrane materials in dam construction.

| Parameter | HDPE Liner | LDPE Liner | PVC Liner | EPDM Rubber |

|---|---|---|---|---|

| Impermeability | Excellent | Good | Good | Excellent |

| Chemical Resistance | Very High | Medium | Medium | High |

| UV Resistance | High | Medium | Low | High |

| Service Life | 20–50 Years | 10–20 Years | 8–15 Years | 20–30 Years |

| Engineering Use | Dams, reservoirs | Ponds | Landscaping | Decorative ponds |

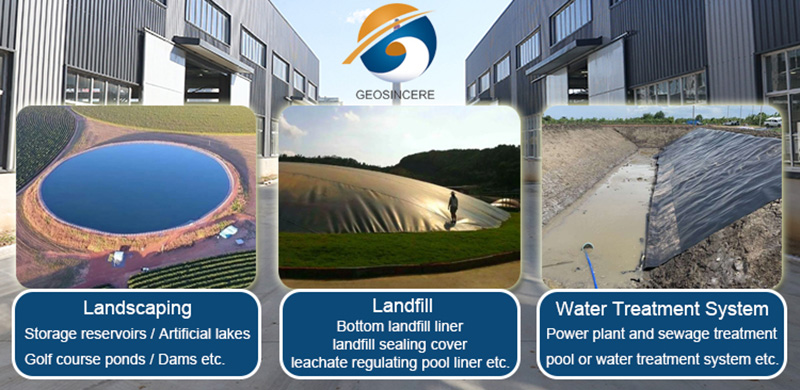

Application Scenarios

Dam Plastic HDPE Pond Liner Material is widely specified across hydraulic and environmental projects.

Distributors: Supplying standardized liner rolls for regional infrastructure projects

EPC Contractors: Dams, reservoirs, irrigation canals, tailings ponds

Engineering Firms: Seepage control design and material specification

Project Owners: Long-term water containment and environmental compliance

Core Pain Points and Solutions

Seepage leakage: HDPE’s low permeability ensures effective water containment

UV degradation: Carbon black stabilized formulation extends outdoor service life

Subgrade damage: Proper cushioning layers reduce puncture risk

Joint failure: Hot wedge welding ensures consistent seam strength

Risk Warnings and Mitigation Strategies

Improper installation or material selection can result in liner failure. Risks include inadequate subgrade preparation, insufficient seam testing, and using non-certified materials.

Mitigation measures include geotechnical assessment, certified welding technicians, non-destructive seam testing, and documented quality control procedures.

Procurement Selection Guide

Define hydraulic and environmental design requirements

Select liner thickness based on water depth and load

Confirm applicable standards and certifications

Evaluate chemical and UV exposure conditions

Review manufacturer production capacity and QC system

Request physical samples and test reports

Assess logistics and on-site welding support

Engineering Case Example

In a 120,000 m² agricultural reservoir project, 1.5 mm HDPE pond liner was installed to control seepage and reduce water loss. The liner was hot-wedge welded on site, followed by vacuum box testing, achieving long-term leak prevention under variable water levels and seasonal temperature changes.

FAQ

Q1: What thickness is commonly used for dam liners?

A: 1.0–2.0 mm depending on design load.Q2: Is HDPE liner suitable for drinking water?

A: Yes, with certified raw materials.Q3: How are seams joined on site?

A: Hot wedge or extrusion welding.Q4: Can HDPE liner be exposed to sunlight?

A: Yes, UV-stabilized grades are designed for exposure.Q5: What is the expected service life?

A: Typically 20–50 years.Q6: Does HDPE liner resist chemicals?

A: Yes, excellent resistance to most acids and alkalis.Q7: Is cushioning layer required?

A: Recommended for rough subgrades.Q8: How is seam quality tested?

A: Vacuum box or air pressure testing.Q9: Can liners be repaired after damage?

A: Yes, by extrusion welding patches.Q10: Are custom roll sizes available?

A: Yes, subject to production capacity.

Call to Action

For project-specific quotations, technical datasheets, or engineering samples of Dam Plastic HDPE Pond Liner Material, please submit your design requirements, project location, and required standards to our technical team.

E-E-A-T Author Credentials

This technical guide is authored by a geosynthetics engineering specialist with over 15 years of experience in HDPE geomembrane manufacturing, dam seepage control, and international EPC project support across water, mining, and environmental sectors.