HDPE Reinforced Polyethylene Geomembrane for Dam Project

HDPE reinforced polyethylene geomembrane is a suitable choice for dam projects that require a robust and durable liner to ensure water containment and prevent seepage. HDPE reinforced polyethylene geomembranes combine the advantages of HDPE and polyethylene materials.Provides excellent durability, chemical resistance, and UV resistance, while the reinforcement enhances the liner's strength and tear resistance.

One of the primary purposes of a dam liner is to prevent water seepage through the dam structure. HDPE reinforced polyethylene geomembranes offer a high level of impermeability, effectively minimizing seepage and ensuring water containment.Dams are exposed to sunlight, and prolonged UV exposure can degrade unprotected geomembranes. HDPE reinforced polyethylene geomembranes typically incorporate UV stabilizers, providing excellent resistance to UV radiation and ensuring long-term durability.

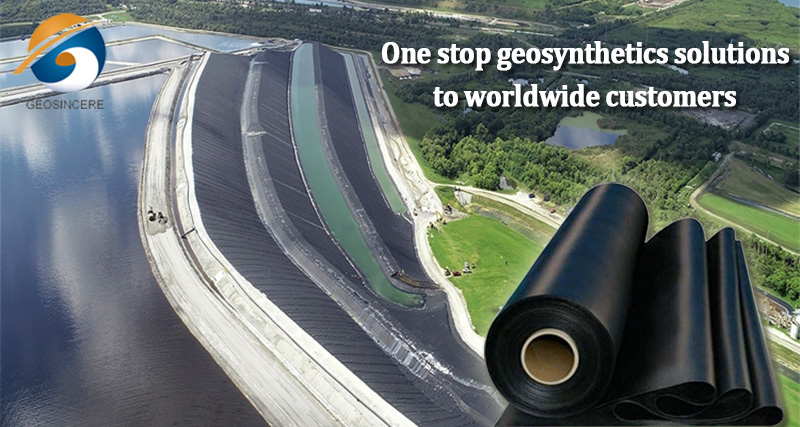

In large-scale infrastructure such as dams and reservoirs, long-term waterproofing and structural integrity are critical. That’s why engineers and construction professionals turn to HDPE Reinforced Polyethylene Geomembrane for Dam Projects—a high-performance liner system designed to resist extreme weather, hydrostatic pressure, and environmental degradation.

The HDPE Reinforced Polyethylene Geomembrane for Dam Project combines exceptional tensile strength with proven impermeability, making it the industry’s preferred solution for dam lining, embankment sealing, and water retention.

What Is HDPE Reinforced Polyethylene Geomembrane?

HDPE Reinforced Polyethylene Geomembrane for Dam Project is a multilayered composite liner made from high-density polyethylene (HDPE), often reinforced with a woven or nonwoven fabric core for superior dimensional stability and tear resistance.

With excellent chemical resistance, UV durability, and thermal stability, this geomembrane is specifically engineered to serve as a robust barrier in dam construction, irrigation canals, and hydraulic containment systems.

Key Features of HDPE Reinforced Polyethylene Geomembrane for Dam Project

✔ High-Density Polyethylene (HDPE) Material

Ensures outstanding chemical and UV resistance in outdoor dam environments.

✔ Reinforced Core Layer

Provides superior tensile strength and tear resistance, even under high water pressure.

✔ 1.0mm–2.5mm Thickness Options

Customizable to suit project specifications and engineering requirements.

✔ Textured or Smooth Surface

Improves friction angle for slope stability or provides ease of welding.

✔ Long Service Life (50+ Years)

Designed for permanent water retention and structural performance in dam applications.

✔ Easy Weldability & Installation

Can be heat-welded on-site for seamless water barrier performance.

Why Use HDPE Reinforced Polyethylene Geomembrane for Dam Project?

When managing billions of gallons of water, even a micro-leak could result in ecological harm, soil erosion, or structural failure. The HDPE Reinforced Polyethylene Geomembrane for Dam Project eliminates these risks by providing:

Total Impermeability: Prevents seepage and groundwater contamination

High Pressure Resistance: Withstands water loads in tall or steep dams

Slope Protection: Enhances liner stability on angled or curved embankments

Environmental Compliance: Meets global environmental safety standards

Cost Efficiency: Reduces the need for traditional clay cores or concrete linings

Applications of HDPE Reinforced Polyethylene Geomembrane for Dam Project

The HDPE Reinforced Polyethylene Geomembrane for Dam Project is ideal for:

Earth-fill dam waterproofing

Embankment lining systems

Hydraulic canal sealing

Irrigation reservoir containment

Flood control dams

Drinking water retention dams

Hydroelectric power dams

Its flexibility and high strength make it adaptable for both new construction and rehabilitation projects.

Technical Specifications

| Property | Specification |

|---|---|

| Material | HDPE with reinforced core |

| Thickness | 1.0 mm – 2.5 mm |

| Width | Up to 8 meters |

| Color | Black / White / Green |

| Tensile Strength | ≥ 28 MPa |

| Puncture Resistance | High (ASTM D4833 standard) |

| Seam Strength | ≥ 90% of parent material |

| UV Resistance | Excellent (20+ years exposure) |

| Service Life | 50+ years under proper installation |

Installation Guidelines for Dam Projects

Subgrade Preparation: Remove rocks and sharp objects, compact the base.

Unrolling & Positioning: Carefully place the HDPE Reinforced Polyethylene Geomembrane for Dam Project using approved equipment.

Welding Process: Use hot wedge or extrusion welding for seam joining; double-weld seams with air channel for pressure testing.

Anchoring: Secure liner in perimeter trenches or concrete anchor beams.

Inspection & Testing: Conduct onsite vacuum box or air pressure testing to verify seam integrity.

Always follow international standards such as GRI GM13, ASTM, and ISO 9001 during installation and QA/QC procedures.

Certifications & Compliance

The HDPE Reinforced Polyethylene Geomembrane for Dam Project complies with:

GRI GM13 (HDPE geomembrane quality standard)

ISO 9001/14001 Quality and Environmental Management Systems

ASTM D638 / D6693 / D5397 testing procedures

RoHS / REACH standards for environmental safety

CE Marking (for European projects)

Conclusion

For any dam construction or reservoir containment project, using the HDPE Reinforced Polyethylene Geomembrane for Dam Project is the smartest choice to ensure watertight protection, environmental compliance, and long-term durability.

This reinforced geomembrane offers unmatched value by preventing seepage, reducing maintenance, and extending the lifespan of critical water infrastructure.

Choose the HDPE Reinforced Polyethylene Geomembrane for Dam Project and safeguard your investment with a liner that meets global engineering standards and delivers performance you can count on.

Chemical Resistance, HDPE geomembranes exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, and hydrocarbons. This chemical resistance is crucial in dam projects where the liner must withstand exposure to various water compositions and potential contaminants.Durability and Longevity, HDPE reinforced polyethylene geomembranes are designed to have a long service life, typically exceeding several decades. They are resistant to UV radiation, weathering, and biological degradation, ensuring their durability and performance over time.