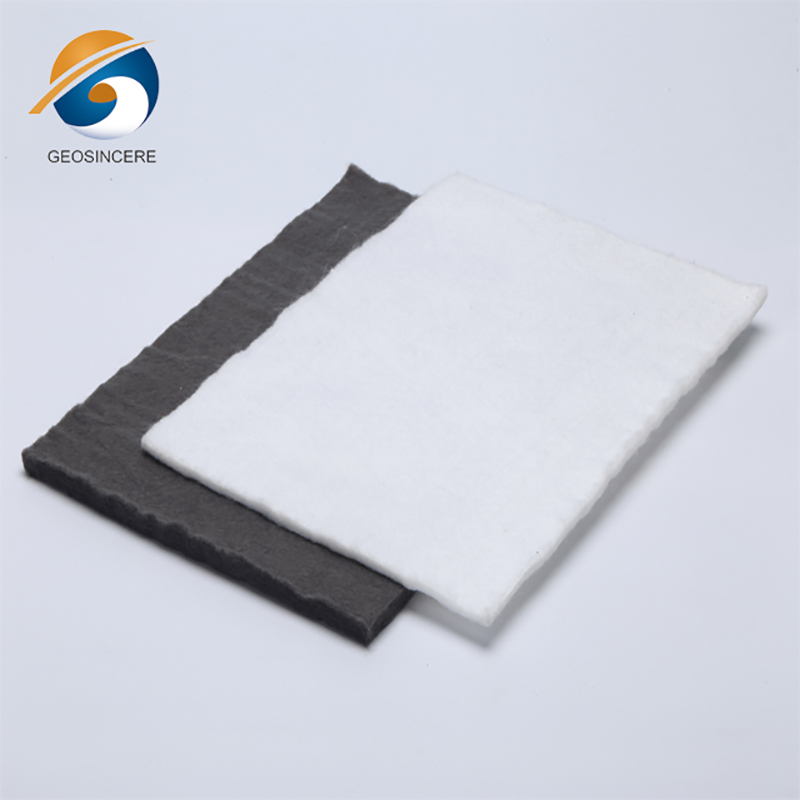

Nonwoven Polyester Permeable Geotextile Separation Fabric

Manufacturing Process

The manufacturing process of Nonwoven Polyester Permeable Geotextile Separation Fabric directly influences its filtration efficiency, strength uniformity, and service life.

Engineering Manufacturing Steps

Polyester fiber selection and quality inspection

Fiber opening, blending, and carding

Web formation and layering

Needle punching for mechanical bonding

Thermal setting and thickness stabilization

Online inspection for mass and tensile consistency

Roll cutting, labeling, and packaging

High-speed needle looms, automatic weight control systems, and tensile testing equipment are essential to ensure compliance with engineering standards.

Product Definition

Nonwoven Polyester Permeable Geotextile Separation Fabric is a needle-punched geosynthetic material engineered for separation, filtration, drainage, and protection in civil and infrastructure projects. It allows controlled water flow while preventing soil migration, ensuring long-term structural stability of roadbeds, foundations, and hydraulic systems.

Technical Parameters and Specifications

The following parameters are commonly specified in EPC tenders and infrastructure design documents for Nonwoven Polyester Permeable Geotextile Separation Fabric.

Raw material: 100% Polyester (PET)

Manufacturing method: Needle-punched nonwoven

Mass per unit area: 100 – 800 g/m²

Thickness (2 kPa): 0.8 – 4.5 mm

Tensile strength (MD/CD): 6 – 25 kN/m

Elongation at break: 40% – 80%

CBR puncture resistance: 1.0 – 6.5 kN

Permeability coefficient: ≥ 1 × 10⁻³ m/s

Apparent opening size (O90): 0.07 – 0.20 mm

UV resistance: ≥ 70% strength retained after 500 h

Operating temperature range: -40°C to +120°C

Structure and Material Composition

Nonwoven Polyester Permeable Geotextile Separation Fabric has a uniform three-dimensional fiber structure that provides both mechanical strength and hydraulic performance.

Structural Composition

Polyester Continuous or Staple Fibers: Provide tensile strength and chemical stability

Needle-Punched Fiber Network: Creates high porosity and permeability

Thermal or Mechanical Bonding Points: Enhance dimensional stability

Open Pore Channels: Enable effective filtration and drainage

Manufacturing Process

The manufacturing process of Nonwoven Polyester Permeable Geotextile Separation Fabric directly influences its filtration efficiency, strength uniformity, and service life.

Engineering Manufacturing Steps

Polyester fiber selection and quality inspection

Fiber opening, blending, and carding

Web formation and layering

Needle punching for mechanical bonding

Thermal setting and thickness stabilization

Online inspection for mass and tensile consistency

Roll cutting, labeling, and packaging

High-speed needle looms, automatic weight control systems, and tensile testing equipment are essential to ensure compliance with engineering standards.

Industry Comparison

Nonwoven polyester geotextiles are often compared with other geosynthetic materials used for separation and filtration.

| Parameter | Nonwoven PET Geotextile | Woven Geotextile | Polypropylene Nonwoven | Gravel Filter Layer |

|---|---|---|---|---|

| Permeability | Excellent | Moderate | Good | High |

| Filtration Control | Precise | Limited | Moderate | Poor |

| Installation Efficiency | High | Medium | High | Low |

| Durability | High | High | Medium | Variable |

| Typical Use | Separation & filtration | Reinforcement | Drainage | Traditional filtering |

Application Scenarios

Nonwoven Polyester Permeable Geotextile Separation Fabric is widely applied across civil, transportation, and environmental engineering projects.

Distributors: Supplying standardized geotextiles for regional infrastructure markets

EPC Contractors: Roads, railways, airports, retaining structures

Engineering Consultants: Filtration and separation layer design

Project Owners: Long-term performance and reduced maintenance cost

Core Pain Points and Solutions

Soil contamination: Geotextile prevents fine particle migration between layers

Poor drainage: High permeability maintains continuous water flow

Base course deformation: Separation function preserves aggregate integrity

Complex installation: Lightweight rolls improve construction efficiency

Risk Warnings and Mitigation Strategies

Improper selection or installation may reduce performance. Risks include clogging due to incorrect opening size, mechanical damage during backfilling, and insufficient overlap.

Mitigation strategies involve soil compatibility analysis, protective layers during installation, and adherence to specified overlap and anchoring requirements.

Procurement Selection Guide

Analyze soil gradation and hydraulic requirements

Select appropriate mass per unit area

Verify tensile and puncture strength requirements

Confirm applicable standards and test methods

Review manufacturer production capability and QC system

Request samples and laboratory test reports

Evaluate logistics, roll sizes, and delivery schedule

Engineering Case Example

In a highway subgrade rehabilitation project covering 35 km, 300 g/m² nonwoven polyester permeable geotextile separation fabric was installed between soft clay subsoil and crushed stone base. The solution significantly reduced rutting, improved drainage, and extended pavement service life under heavy traffic loads.

FAQ

Q1: What is the main function of this geotextile?

A: Separation and filtration.Q2: Is polyester suitable for alkaline soils?

A: Yes, polyester has good chemical resistance.Q3: What grammage is typical for road projects?

A: 200–400 g/m².Q4: Can it be used under riprap?

A: Yes, with sufficient puncture resistance.Q5: How is permeability measured?

A: According to standardized hydraulic tests.Q6: Does it replace sand filters?

A: In many cases, yes.Q7: What overlap is recommended?

A: Typically 300–500 mm.Q8: Is UV exposure allowed?

A: Short-term exposure is acceptable.Q9: How long is the service life?

A: Often exceeds 25 years when properly installed.Q10: Are custom roll sizes available?

A: Yes, depending on production capacity.

Call to Action

To request quotations, technical datasheets, or engineering samples of Nonwoven Polyester Permeable Geotextile Separation Fabric, please provide your project specifications, soil conditions, and applicable standards to our technical team.

E-E-A-T Author Credentials

This article is authored by a civil and geosynthetics engineering specialist with more than 15 years of experience in geotextile manufacturing, infrastructure project design support, and EPC material procurement for transportation, hydraulic, and environmental engineering projects.